Bringing fantasy to life: DIY stainless steel smokehouse

A stainless steel smokehouse is an assistant for lovers of home-made smoked meats. Its it's easy to do it yourself, if you know the manufacturing process of the device in all details.

At the same time, making your own smokehouse has a lot of advantages: the ability to choose any design, which is limited only by the author’s imagination, the use of high-quality materials, and saving money.

Content

Types of household smokehouses with a stainless steel water seal

Stainless steel smokehouses have a lot of advantages: light weight, durability, tightness, ease of carrying. Such structures are made of sheet metal - stainless steel. In order to prepare stainless steel for use, it is necessary to carefully clean it from dirt and dustIf there are dents on thin canvases, they are leveled with a hammer.

Photo 1. Homemade smokehouse made of stainless steel. The build quality is no worse than that of factory analogues.

Most owners of factory-made stainless steel smokehouses are unhappy with the main drawback of the devices - small thickness of metalThe miniature size of these products, as well as the thin-walled gratings, are also depressing.

A smokehouse made by hand is deprived of all this. The master has complete freedom of choice of both materials and design modifications. But the principles of the smokehouse device when creating them must be observed.

Any device for preparing smoked products consists of several main parts:

- smoking chamber;

- fireboxes;

- chimney.

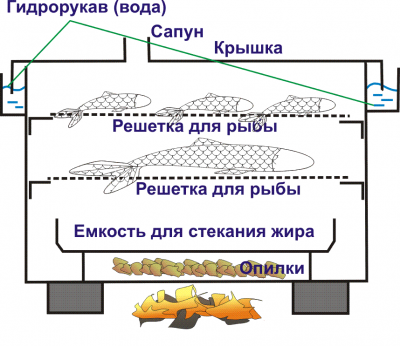

Among the secondary elements - doors, control devices, equipment for laying and hanging products (grids and hooks). A stainless steel smokehouse can be equipped with a water seal, which is otherwise called a water lock.

Task water seal — prevent air from getting inside the smoking chamber and prevent smoke and odor from escaping from it. In the first case, the issue of sawdust combustion is resolved, and in the second, the comfort of cooking smoked meats at home is ensured.

A stainless steel smokehouse is always a lightweight, portable design. It consists of several elements:

- from a metal sealed box with handles (medium sizes 500x300x300 mm);

- from flat, triangular or semi-oval caps with soldered hollow tube for smoke removal;

- from pallet on short legs (designed to collect fat dripping from food products);

- from two gratings, located in two tiers;

- can be built into the lid thermometer.

A firebox and chimney are not provided for this type of smokehouse. It works on the principle of hot smoking. Sawdust and shavings for smoking are placed directly to the bottom of the chamber. The smoke is released through a hole in the lid. If the process of preparing delicious food takes place at home, a hose of the appropriate diameter and take it outside the apartment, for example, through a window.

Making a smokehouse with your own hands from stainless steel 2 and 3 mm thick. Drawings

Detailed instructions for making a stainless steel smokehouse are provided. 2 mm thick with parameters:

- height 280 mm;

- length 520 mm;

- width 310 mm.

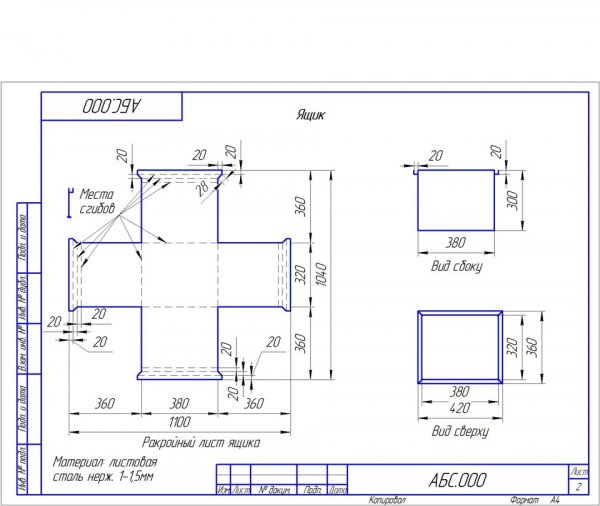

Photo 2. Drawing of a stainless steel smokehouse. Cut-out view, side view and top view. The device can be of any size.

To work you will need the following materials and tools:

- stainless steel thickness 2 mm;

- metal corner 15x15 mm;

- metal rods with a cross-section of not less than 2 mm;

- roulette;

- simple pencil;

- square;

- Angle grinder (Bulgarian);

- disc for metal thickness 1-1.5 mm;

- metal tube cross-section 8-10 mm and length 2.5-3 cm;

- a wooden block of any section, not less than 520 mm.

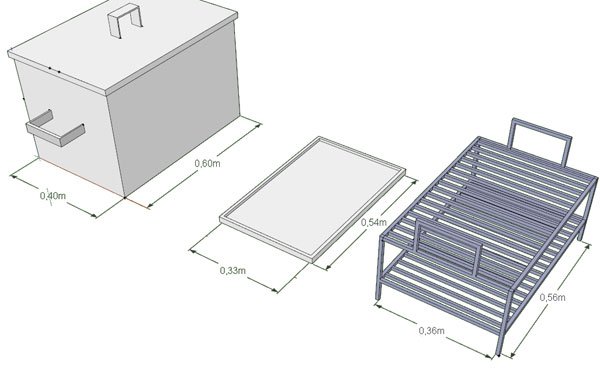

Photo 3. Drawing of all parts (box, tray, grate) of a stainless steel smokehouse with the dimensions of the structure indicated.

All elements of the device are manufactured from the same material. But the handles for the camera and lid can be made from anything non-flammable. These can be fireproof handles from saucepans or other kitchen utensils.

Selecting a project

A stainless steel smokehouse can be any geometric shape: square, rectangular, round. The second form is universal. Suitable for both home and field conditions.

A round design is chosen if you need to prepare a large amount of products in one smoking session. Such devices are in many ways similar to massive tanks. They are difficult to move, so it is recommended to determine a permanent location for the device.

In order to make the task of making a smokehouse easier, you need to do drawing of the future device. School knowledge of geometry and mathematics will help with this. Universal smokehouses made of stainless steel consist of many rectangles of different sizes. It is necessary to determine length, height and width the main element - the smoking chamber. After that, it will not be difficult to make a drawing of the lid, grates and tray.

How to select materials

Factory smokehouses are made of stainless steel with a thickness 1.5 mm (camera and lid) and 0.8 mm (grids and tray).

Practice has shown that this material has a number of disadvantages: when heated, the metal bends, and the grates also bend under the weight of the food.

Therefore, for the manufacture of a homemade device, it is recommended to choose a metal of thickness from 2 mm.

If you plan to create a stationary large-sized smokehouse, you will need metal with a thickness not less than 3 mm.

Reference. The best choice would be food grade stainless steel. AISI 304 or its equivalent 08Х18Н10.

Thickness of steel AISI 304 from 0.8 to 50 mm. The surface of these metal sheets there are 3 types:

- mirror;

- semi-mirror (polished);

- matte.

Manufacturing of the case

Step 1. Using a grinder or metal scissors, cut out a strip of steel of length 166 cm and height 280 mm.

Step 2. Mark the places where the canvas will be folded:

- measure out 520 mm, draw a vertical line;

- measure from this line 310 mm and draw a vertical line;

- they measure again 520 mm.

Step 3. Take a grinder with a metal disc and make cuts no deeper than 1 mm strictly along the previously drawn lines.

Step 4. Bend the metal strip at the cut points. For greater convenience, use a wooden block whose length exceeds the width of the metal sheet. The result should be a hollow box.

Step 5. Weld the two sides of the box together. Clean and level the weld seam.

Step 6. A rectangle measuring 540x330 mm. This is how you get a bottom, on each side of which there will be a bend 1 cm towards the smoking chamber.

Step 7. On this canvas, draw 4 lines along the perimeter of the rectangle, stepping back from its edges by 1 cm.

Step 8. In the same way as with the box, cuts are made and the edges of the bottom are bent.

Step 9. The box is inserted into the bottom and welded along the perimeter. The quality of the weld is checked by pouring water into the resulting container.

Step 10. They make a water seal by welding a corner around the perimeter of the box. 15x15 mm.

The end of the vertical shelf of the corner should not be on the same level with the upper plane of the box, but below it by 3-5 mmThis is necessary so that in case of overflow of the water seal, water does not get into the smoking chamber.

Step 11. A rectangle of the size is cut out of a sheet of steel 542x332 mm and make the smokehouse lid. They weld the handles to it or fasten them with bolts.

Step 12. A hole with a cross-section is drilled in the lid 8-10 mm. A metal tube of length is welded to it. 2.5—3 cm.

Smokehouse base

The base of the smokehouse is its legs. They can be made from metal corners or pieces. reinforcementThe selected material is cut into pieces of the required length using a grinder and welded using a welding machine and electrodes.

What to weld the grate from

From metal rods weld the grate. The legs and upper pins of the grate are also made from them. A metal tube will be put on these protrusions, into which the grate of the second tier is inserted from above.

The second grate is made in a similar manner. It should not have pins at the top.

Photo 4. A variant of making a grate for a smokehouse from an old metal dumpling mold.

Pallet

A rectangle measuring 535x325 mm. Draw a line on each side of the rectangle. 1 cm and make cuts for the bends. Bend the sides of the canvas and weld them in the corners. This is how you get a pallet. Weld legs to it of length 2-3 cm.

Smokehouse assembly

Insert the tray and grates into the smokehouse and close the lid. The device is ready for operation..

Recommendations for using a stainless steel hot smoker

In order to prevent spontaneous combustion of sawdust, the device protect from the wind.

Attention! If smoking takes place at home, draft is unacceptable.

When preparing smoked meats outdoors, they try to find windless place: near the walls of buildings made of brick or concrete, next to a metal fence.

Fire safety regulations must be observed. Stainless steel smokehouses are heated by open fire in most cases. At home, the device is installed on a gas or electric stoveu. The design is safe, but still requires attention during the smoking session.

Useful video

Watch an interesting video that shows step by step the process of making a smokehouse from stainless steel.

Comments