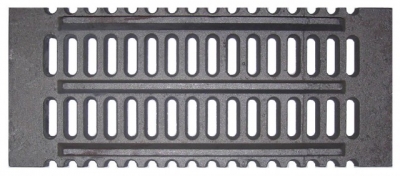

And let all the fuel burn to the end! A cast iron grate is a necessary thing for any stove

The grate is a grate that is installed between the firebox and the ash pan of the furnace. It promotes more efficient combustion of fuel.

After part of it has burned, the ash falls down through the holes. The remaining part goes down and burns more intensely, because air enters through the grille.

The part is made from materials that are resistant to temperature effects: cast iron or heat-resistant steelAt the same time, cast iron grates last longer, as they are more durable.

Technical specifications

There are many types of furnaces, differing in size, type of fuel used and other characteristics. Therefore, the grates for them will also be different. As for the material of the furnace itself, it does not directly affect the choice. The grates are installed in brick, steel and cast iron devices.

Type of construction

There are different types of gratings:

- monolithic;

- typesetting;

- cooled.

Monolithic — these are solid structures. The dimensions are selected depending on the depth and width of the firebox.

Available to fit all standard firebox sizes, this option is the easiest to install.

Typesetting option It is made up of separate rod elements. It is used if a standard one cannot be found, for example, in non-factory-made furnaces.

Important! Often the rods are wedge-shaped. When installing them, they are positioned with the narrower part down. This increases the service life.

Cooled are used in systems with heat exchangers. They are made of tubes through which the coolant passes. Thus, the grate itself is cooled, and the overall efficiency increases. This option is more often used in solid fuel boilers. The temperature inside the chamber reaches 1000°С. Thanks to cooling, the material can withstand such thermal load.

Form

The grates differ in the shape of the web. Different types are used in different designs. The following types of gratings are produced:

- flat;

- basket;

- movable;

- beam.

Photo 1. Basket grate made of cast iron. This type of device is usually installed in fireplaces.

Flat (or tiled) — the most common type. They are installed not only in stoves, but also in solid fuel boilers, as well as in fireplaces. They have a rectangular shape. The dimensions are standard, selected depending on the dimensions of the fuel chamber.

At the basket edges bent upwards, due to which the whole structure resembles a basket. Such structures are placed in open-type ovens intended for cooking. Since such ovens are rare nowadays, and the parts for them are also not very common.

Movable grates are installed in long-burning furnaces where it is necessary to regulate the air flow. The design provides for the possibility of changing the width of the gaps. They have several sections and a shaft, due to which movement occurs. The rotation axes can be horizontal or vertical. An additional advantage is greater convenience during cleaning.

Beam consist of individual crossbars (beams), which can be single or double. They are usually used in non-standard sized ovens.

Size

The dimensions of the product depend on two parameters:

- dimensions of the furnace combustion chamber;

- type of fuel used.

In equipment that runs on firewood, peat and fuel briquettes, the width most often used is in 150-350 mm (in 50 mm increments).

The depth is usually 180 or 250 mm. The largest possible sizes of standard models are 900x800 mm.

When coal burns, more harmful substances are formed. Therefore, the grate size should be larger, from 300-350 mm on both sides.

In any case, gaps are left along the edges not less than 5 mm. They serve to compensate for expansion during heating.

Attention! When choosing a size the weight of one fuel load is also taken into accountThe dimensions, especially the thickness, are selected in such a way that to withstand this load.

Recommendations for choosing cast iron grates for a furnace

A correctly selected grate increases the efficiency of the furnace and reduces fuel consumption. Which option is best depends on:

- type of stove;

- dimensions of the firebox;

- fuel used.

Type of stove

Each type of grate is better Suitable for a specific type of heating appliance. For ordinary tiled stoves and fireplaces are suitable. solid fuel It is better to install cooled boilers. Although flat ones are also used, especially in small models.

For long burning devices choose a movable option for better air flow control. And when using open When it comes to stoves, it makes sense to opt for a basket model.

Photo 2. An open fireplace with a cast iron basket-type grate installed in it.

Fuel type

If the stove or boiler is fired with coal, it is selected larger grilleWhen coal burns, more harmful substances are released, and if there are not enough holes, they will become clogged.

Important! Fuel must not be extinguished with cold water. Sharp temperature changes reduce the durability of cast iron, and the grate breaks over time.

Firebox size

The size of the grate depends on it. It is also taken into account distance between the grate and the walls.

Standard gratings are selected for standard chamber sizes. If this is not possible, the detail is made up of individual beams.

Width of the lattice gaps

The size of the holes themselves is also important. Ash should fall into them, but not small pieces of coal or wood.

The total volume of the lumens is usually not less than 40% of the grate areaOtherwise, there will be insufficient air supply and combustion efficiency will decrease.

Useful video

Watch the video to learn how to make a stainless steel grate with your own hands.

Pros and Cons of Using Cast Iron Stove Grate

The grate is a necessary part of the furnace design, without which the fuel burns much worse. used in all types of stoves and fireplaces, and also in solid fuel boilers.

As materials heat-resistant steel or cast iron is used. The first option is cheaper, but lasts less because it is subject to corrosion.

Cast iron is more durable and can withstand high temperatures better. However, it is a rather fragile material, so cast iron parts must be handled with extreme care during installation.

Comments