How to make an expansion tank for open heating with your own hands: photos and instructions

In individual heating systems they are installed expansion tank.

The main objective pursued during installation is: compensation for changes in liquid volume when heated.

Content

Purpose of the expansion tank

In fact, when the temperature changes, pipelines and heating devices change the internal volume filled with the coolant insignificantly. Water is most often used as a coolant in heating systems, which, when heated to a temperature 90—95 °C can increase volume by 2.5-2.8%.

Attention! Excess liquid is directed into a special container, which is located above all in the heating system.

Another problem that is solved when installing an expansion tank is that the presence of such a container allows you to fill the system with coolant.

In order for the flow of liquid to circulate through pipelines and heating devices, the condition of continuity of flow is observed (Daniel Bernoulli wrote about him in the mid-18th century).

Continuity of flow - absence of places where there is no water. The presence of voids will create a condition in which the existing gas bubbles will not allow the liquid to move.

A similar phenomenon is observed at the beginning of the heating season, and air locks, which are removed by filling the system with water. Excess liquid is located on top in a special container.

Reference! Natural circulation within a closed space is only possible if there is a certain hydrostatic head (Hst). The higher the value of Hst, the more intensive the circulation of the coolant occurs.

When the coolant temperature decreases there is a decrease in volume. Some of the water from the expansion tank returns to the heating system.

Types

Heating systems perform with natural and forced circulation coolant.

In traditional heating designs, expansion tanks are used. open type.

In cases where the coolant is forced into motion by means of special circulation pumps, expansion devices are more often used. closed type.

Open type

An open expansion tank is a regular metal box connected to a pipe from the heating main. It is placed in the highest accessible place buildings (houses).

During the heating season, regularly check the presence of water in the tank. If necessary, add liquid to the expansion tank.

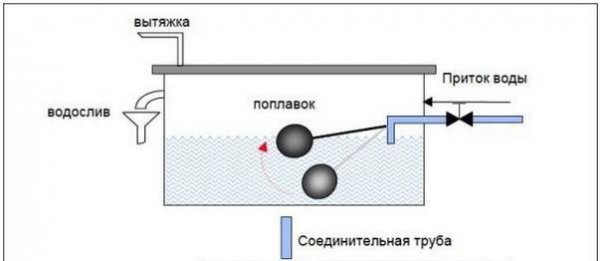

Some experts are installing float system control the level in the expansion tank. When the level drops, the float drops, which leads to the opening of the feeder valve.

Water is automatically added to the required level. Automatic systems are installed only where there is a water supply that maintains pressure exceeding hydrostatic value Hst.

Advantages of an open system:

- Extremely simple device, easy to make with your own hands.

- Maybe function for years, without causing any complaints from users.

Disadvantages of an open system:

- Corrosion damages expansion tank first of all.

- It is necessary to monitor regularly presence of liquid and top up if necessary. Often in private houses, when installing a heating system, the capacity for expansion of the coolant is remembered last. I place it near the ceiling, which creates inconvenience when topping up. We are forced to use flat bottlesto add water.

- It is necessary to lay additional pipe, which will heat only the space near the ceiling.

Important! The coolant tends to evaporate. It needs to be topped up periodically to prevent build-up inside the heating system. air locks.

Closed tank

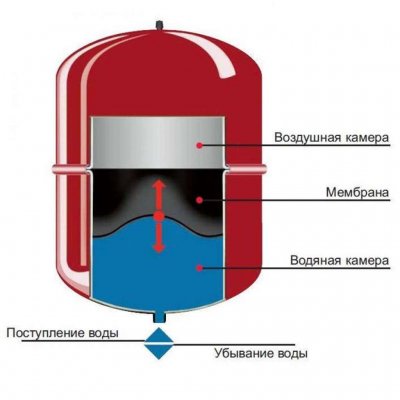

These tanks have two volumes separated by a movable membraneThe lower space contains the coolant, and the upper space contains ordinary air.

To create preliminary pressure in the system, the air part of the tank is provided with valve and nippleBy connecting a pump, you can increase the pressure inside the air chamber.

The pressure gauge is used to control and set set pressure in the heating system Hst.

Installation of such a device is carried out in different parts of the heating system, more often it is traditionally installed near the boiler on the supply line.

Some users install additional taps and pressure gauges to know the pressure value during operation.

Positive indicators closed system:

- There is no need to constantly monitor the coolant level in the system, having filled it once, over several years you don't have to worry about filling.

- Antifreeze liquids (high-boiling alcohols) are added to the coolant, which are not afraid of temperatures dropping below 0 °C, which is important for country houses that are visited only occasionally.

- No metal corrosion, since air does not enter inside.

Minus conditional. It is necessary to equip a closed heating system control devices, as well as a safety valve, which will open in the event of a sharp increase in pressure.

Attention! A sharp increase in pressure in the coolant is possible only if its circulation will stopThis may happen if the circulation pump is damaged or disconnected.

There is another drawback that manufacturers of closed tanks do not want to talk about. The membrane loses elasticity over time. Damage will occur when the pressure inside changes. That is why there are detachable tanks on sale. It is easy to replace the membrane in them after a certain time. Usually, such maintenance is done in the summer, preparing for the new heating season.

Making an expansion tank with your own hands: photo

You should start work by creating drawing or sketch future product. At the same time, the materials and tools for making the expansion tank available to the home craftsman are evaluated.

Photo 1. This is what the diagram of an open expansion tank with a float water level control system looks like.

Tank capacity for a heating system of a separate house or apartment

Only during operation will it be noticeable how quickly the coolant evaporates. Frequent filling will be required. Many people think that a small volume is needed. There are recommendations that it is enough for the expansion tank to have capacity of 5-7 liters. Of course, it is easier to find or make such a volume.

When changing the boiler operating mode (even in winter there are thaws, when the heating of the coolant is carried out to a temperature of only 40—45 °C). From the expansion tank, water can completely go into the system.

Reference! In practice, it has been proven that the minimum required capacity is not less than 10% from the total volume of the entire system.

Calculating the volume of the expansion tank is easy. The length of the pipelines is determined, as well as the number of sections in all batteries. For example, for a house with an area of about 100 sq.m. the volume of the heating system is 120-140 l. Then the expansion tank should be not less than 12-14 l. You can add a little more so that you need to add water less often.

Direct manufacturing

When a home craftsman starts work, he has the following options:

- a ready-made container is used, for example, a large saucepan, a milk jug or a can 12-15 l or more;

Photo 2. An expansion tank can be made from various containers, including a similar aluminum flask.

- in stock available sheet metal and welding machine.

How to make it from a plastic canister

It's easier with ready-made containers. You need to have an electric drill with a set of drills. The process comes down to drilling a hole into which you can run a pipe diameter 21-27 mm.

- Find a drill so large diameter It can be difficult at home. Therefore, a circle is marked out and then holes are drilled along the contour.

- Using a file, grind down jumpers and give the hole an acceptable appearance.

- They use wide washers, rubber gaskets and nuts with the required pipe thread.

- They assemble the future structure and set higher, preferably in the attic.

- To prevent intense evaporation cover with lids.

- To avoid freezing in winter they provide additional insulation. They use old warm clothes or various insulation materials, for example, "Ursa".

This method of manufacturing an expansion tank is the least expensive.

Important! If you have a milk flask with a capacity of 40 l, then it is most convenient to use it to create an expansion tank for the heating system. The lid does not close tightly during operation, the rubber gasket is removed.

Manufactured from sheet material

Certain requirements are imposed on the source material. The thickness of the sheets must be not less than 4 mm. When using a sheet with a lower thickness, the service life may be limited to only a few seasons.

After purchasing the material, we begin to develop a sketch of the expansion tank.

Photo 3. This is what an expansion tank made of sheet material looks like with an air bleed hole and an overflow pipe.

The following tools are required:

- angle grinder (grinder) with cutting discs for metal;

- drill with a set of drills from 3 to 10 mm;

- welding machine with electrodes diameter 3-4 mm.

For assembly, additional devices will be needed to set up and fix the blank sheets. Usually, craftsmen make the simplest jigs that allow you to install the blanks at an angle of 90°.

Attention! When performing any work, it is necessary to observe safety regulations. Use protective glasses or masks, as well as special gloves and a canvas apron.

When marking sheets, scribers with hard alloy tips, rulers and squares are used. The thickness of the saw blade of the angle grinder must be taken into account. It is recommended to use thicker discs. The price is the same as the thin ones, but they wear out more slowly during use.

Reference! When cutting blanks, it is necessary to fix the sheet to workbench, using clamps or special magnets.

You can't weld the entire weld at once, otherwise the workpieces will warp. Therefore First, the entire box of the future product is assembled on several captured points. Only then weld the seams fully.

The welded product is checked using kerosene, which is poured inside and the places where kerosene droplets appear are marked with chalk.

The flammable liquid is completely drained, the box is washed with running water. Only After drying, the seams are welded again, where defects were observed.

The branch pipes are welded especially carefully. Additional stresses may arise in them during installation. The kerosene testing method is mandatory for all branch pipes.

After welding the expansion tank painted using combined primers of the type "3 in 1" (primer-enamel). The interior can also be painted. To do this, paint is poured into the product. The pipes are blocked. Then the box is vigorously turned in different directions. Excess paint is drained through one of the pipes.

Attention! Alkyd enamels dry out within 24 hours. But inside the process of polymerization of the paintwork will continue two to three times longer, which should be taken into account before starting to use.

Installation in the system

After the product is manufactured, it is installed in place. All pipes are connected. For sealing, use linen winding. To prevent further heat loss, the expansion tank is additionally insulated. Any heat-insulating mats, for example, manufactured made of basalt fiber 40 or 50 mm thick. When applied evenly, such insulation will reliably retain heat.

Useful video

Check out the video that shows how to make a homemade expansion tank.

Resume

The expansion tank is the most important device in the heating system, which ensures operability throughout the entire heating period. The simplest tanks can be manufactured home craftsmen on their own. In case of difficulties, it would be better to contact to the specialists.