2 ways to make a stove from a pipe with your own hands. What are the advantages of a homemade design?

Stoves made of steel or iron pipes easy to make and are intended for use in steam rooms, small production workshops and winter work sheds.

Depending on the purpose of the premises, they are selected different diameters and arrangement methods firebox bodies.

Description of typical schemes of stoves from a pipe

The stove made of a pipe is a metal cylinder with holes drilled into it for the firebox and ash pan and a chimney welded on top. There is two main options stoves from pipes:

- horizontal;

- vertical.

Horizontal The models are suitable for baths and industrial premises, as their design provides for installation of the tank for heating water and other auxiliary devices.

On "lying" stoves barbecues and grills are installed for barbecue, which makes them the best option for a garden plot or a summer house.

Vertical The ovens take up a small area and are suitable for heating cabins and cooking in small country kitchens.

Reference. IN vertically located oven firewood burns faster and give more heat, and horizontal the structures melt more slowly, but allow you to retain heat longer with less fuel consumption.

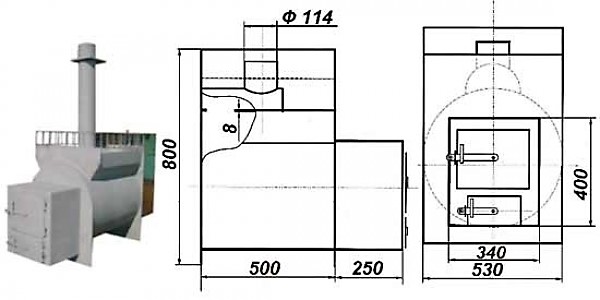

How to do it yourself: drawing 500x530x800

Before starting the installation of the stove, the type of its location is selected and a drawing is being developed taking into account the purpose of the structure, the available area for installation and the availability of the necessary building materials.

Photo 1. Example of a drawing of a homemade sauna stove made from a horizontal pipe. A heater is additionally installed on top.

Selection of materials and tools

The pipe for the stove is being made made of iron or steel diameter 0.4-0.6 m depending on the type of construction. Thickness walls - from 6 to 10 mm, thicker metal is more difficult to process, and thin walls deform at high temperatures.

When determining the diameter and height of the future firebox, the builder is guided by the volume of the heated space and planned fuel consumption, since in a larger firebox the wood burns faster and more heat is released.

Attention! It is not recommended to choose pipes made of high carbon grades steel to avoid cracking of welded seams during operation of the structure.

During the installation process, the builder The following tools and materials will be required:

- welding machine;

- grinder with replaceable discs;

- drill with a drill bit;

- reinforcement;

- steel wire diameter 2.5—3.5 mm;

- chimney pipe diameter 0.15-0.25 m;

- steel angles thickness 4-8 mm;

- sheet steel;

- stove doors and hinges;

- cement and sand;

- formwork boards thickness 1.5—2 cm.

If the stove is being made for a bathhouse, then it is also necessary stainless steel for water tank and tap.

Preparing the site and pipes for assembly

After choosing a project and purchasing materials the space is being cleared under the base in accordance with the drawing. Suitable for horizontal structures pile type of foundation, and for vertical ones - monolithic.

Pouring the foundation for a vertical oven it is done like this:

- A square hole is dug in the soil depth 15-30 cm and side 20-30 cm larger in diameterfirebox.

- The bottom is covered with crushed stone, on top of which reinforcement is laid.

- Wooden formwork is installed on the sides of the pit in such a way that its edges protruded above the ground by 10-15 cm.

- The legs of the future furnace are welded to the upper edges of the reinforcement tie so that their upper edges rise above the formwork. at a height of 10-15 cm.

- Sand is mixed with cement in a ratio of 3:1 and diluted with water to the consistency of sour cream.

- The pit with the reinforcement is filled with ready-made cement mortar up to the top level of the formwork and leveled.

To save solution, it is permissible lay a brick in a hole, fastening it with cement and laying reinforcement. A brick foundation is suitable for a not too massive stove.

Important! For the furnace base are used only fire-resistant grades bricks, since with prolonged use, ordinary bricks are destroyed, which leads to the collapse of the structure.

For reinforcement knitting, rods are used diameter 1-2 cm, which are welded into a lattice with perpendicular projections at the nodes. The upper parts of the legs are leveled with a building level and, if necessary, cut off and welded again.

Reference. The cement solution dries in the pit not less than 7 days, during which the furnace is assembled.

The pipe is prepared by aligning edges to level And grinding down protrusions grinder. If the outer or inner surface is covered with paint, then it is cleaned with grinding discs or sandpaper to avoid the release of toxic substances during the combustion process.

The order of construction of the stove

Construction vertical the furnace is carried out as follows:

- The pipe cylinder is cut off 1-1.5 meters long.

- At a distance of 5 and 20 cm from the bottom the pipes are cut out two rectangular holes for ash pan and firebox with sides 30x5 cm and 30x20 cm respectively.

- A grate with a side equal to the diameter of the furnace is welded from reinforcing bars.

- The grate is given a circular shape by cutting the corners with a grinder so that it can freely enter the cylinder.

- Between the holes for the ash pan and the firebox inside the furnace, welds are placed three corners at equal distances from each other so that the grate rests on them.

- The grate is welded to the supports through the firebox opening.

- It is cut out of sheet steel using a grinder two circles according to the diameter of the pipe, they are welded to its lower and upper base.

- The cylinder is installed on supports protruding from the foundation, with the holes facing down, and welded.

- A hole is made in the top cover equal in diameter to the chimney pipe, which is welded to the stove.

- Hinges are attached to the side and doors are installed.

Bottom thickness the furnace is taken within the limits 6-10 mmIf the design does not have an internal ash pan, and the grate is also the bottom, then length of legs not less than is selected 10 cm. For additional strength, the lower disk is reinforced with corners welded around the circle.

There is a version of the grate made from a sheet of iron with holes drilled in it. diameter 2-3 cmThe grate is installed on the inner corners of the furnace in the same way as the reinforcement grid and is welded.

Reference. To save money, the cut-out part of the cylinder is used as material for the firebox doors and ash pan. compact around the perimeter with steel in strips 2 cm wide, welded on the outside overlapping the edges by 1 cm doors.

After the oven assembly is complete are heating up and if necessary insulate the chimney with glass wool.

Possible difficulties

In a number of cases, during the manufacture and operation of the structure the following problems arise:

- instability of the stove on the foundation;

- jamming of the firebox door;

- weak smoke draft;

- poor weldability of seams.

Unstable position vertical pipe occurs when the brick foundation is poorly made or the legs are not installed evenly when the stove is very high.

To eliminate the problem, bricks are placed under the bottom and short legs are extended by welding thick pieces of reinforcement.

Tightly fitted the doors are jammed due to the expansion of the metal during the heating process. To prevent the doors from sticking, a gap of 6-8 mm between their edges and the hole in the pipe.

Important! Lack of traction occurs when small diameter chimney and his strong fracturesTo ensure sufficient draft, the chimney diameter is selected from 15 cm and bend no more than 40 degrees from the vertical.

For strong welding of seams The corners are selected from the pipe material (steel or iron), and the electrodes are used in accordance with the marking for the specific thickness of the sheets being welded.

Useful video

Check out the video that shows how to make a vertical oven from a 43 cm diameter pipe.

Advantages of a stove made of a pipe

Making a stove with your own hands will allow you save money on purchasing materials and making project according to specific conditions and the goals of the builder.

Form pipes maximum close to spherical, this is ideal for the firebox to produce sufficient heat with low fuel consumption. Plastic metal allows the installation of new elements already during the operation of the finished structure.

And the temperature of such a stove can heat up to 100-110 degrees. If you place the stove as Sergey wrote above, then 100-110 will be in the main part, located in the steam room and 70-80 degrees in the one in the dressing room.

Good luck in making the stove!)