When pipes need to be checked: how are hydraulic tests of a heating system carried out?

Hydraulic tests of the heating system are divided into two categories. Calculation helps to determine the size of communications placed in the building to ensure constant heating.

Cleaning is prescribed when accumulated dirt and rust are detected. This helps restore the original thermal conductivity of pipes if they have become covered with scale during use.

Content

Reasons and frequency of calculation

The calculation is done in two cases: at the design stage buildings or after the heating season. In the first — find the internal diameter of the piping that is sufficient for comfortable heating of the house under construction. In the second determine the ratio of thermal conductivity now to the initial one with the same fuel consumption.

Hydraulic calculation of the heating system: what is it?

The tests must be carried out at outdoor temperatures. at least 5 degrees above 0. The equipment is included in the lower part of the piping, in the return line. Protective panels, if any, are temporarily removed.

Procedure:

- Through the feed pipe system fill with coolant.

- Elevator unit adjust the pressure indicator.

- Employees of the Management Company draw up a report verification results.

Every owner has the right to demand copy documents in hand.

Water consumption for pipeline

The heating system is divided into sections, each of which ends with a radiator. To find the amount of coolant used, use the formula: GV = (860*q)/(∆t*3600*ρ), Where:

- GV — the desired value, l/s.

- q — radiator power, kW;

- Δt — temperature difference between the direct and return risers, °C;

- ρ — density of water, kg/dm33.

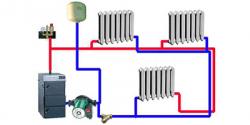

Circulation pump

It is necessary to determine the pressure loss in the system. The result is an indicator that guarantees the passage of water through the piping: Z = P - R*L, Where:

- P — initial pressure, Pa.

- R — specific resistance of pipes to natural friction of liquid against the walls, Pa/m.

- L — length of the harness between two radiators, m.

- Z — pressure loss, Pa.

For two-pipe systems use the sum of the measurements of the direct and return coolants.

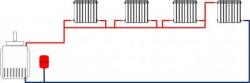

Expansion tank

To calculate, find the length of the piping in the apartment and calculate the number of radiator sections. The capacity is determined by the formula: V = 0.1*(S*L + N*VR), Where:

- V — the required volume, m3.

- S — cross-sectional area of pipes, m2.

- L — harness length, m.

- N — the number of radiator sections, and VR — capacity one, m3.

VR indicate in the passport devices.

Hydro flushing and pressure testing

During operation substances accumulate inside the pipes, settling on the walls. As their number increases, thermal conductivity decreases, which negatively affects the heating of the premises, although the consumption remains the same.

Photo 1. Heating pipes before and after flushing: a large amount of insoluble substances has accumulated on the walls.

The raid leads to damage to property, as fistulas appear, which result in rupture.

Important! The piping is being flushed every year. It is preceded by diagnostics describing the severity and nature of contamination. After cleaning, substances are released through the pipes to create an anti-corrosion coating.

SNiP

Before the start of the heating season, utility services check equipment for compliance with building codes and regulations 3.05.01—85.

Before performing cleaning, the management company employees calculate:

- Length bindings.

- Consumption coolant.

- Pressure systems.

The procedure is carried out in sections.

Requirements

Mandatory briefing for safety personnel performing cleaning.

During the flushing process It is forbidden to approach the harness people not involved in the process. The pipes must be secured and fenced, A check valve air duct - ground in

Hoses carrying compressed gas are equipped with with clamps, then connect with with fittingsThis step prevents slippage under high pressure.

Preparation

Workers take into account the characteristics of each part of the heating circuit, which ensures better cleaning. Before starting the process:

- Research communications.

- They share the harness to the plots.

- If necessary, they install shut-off valves.

- They make calculations, listed above.

- They are conducting hydraulic tests.

Quality preparation ensures results and system protection.

Testing process

Into the feed riser insert a branch pipe with built-in shut-off valves and a check valve. With its help, strong pressure is supplied to the coolant, for which a mixture of water and compressed air is used.

For small systems Only built-in devices may be used. Excess liquid is removed using a tap. If there is an elevator unit, the cone and cup are removed first.

Air supply is provided by compressor. It is enough to clean the pipes 0.6 MPa. A check valve is used to protect the device from liquid ingress. Before starting the pressure, pressure gauges are installed to control the process.

The flushing is done by two methods: flow-through or filling.

- At flowing The pipes are filled with water, leaving the air collector valve open. Then the valve is closed, turning on the supply of compressed gas mixture. The substances are sent to the heating main, starting the cleaning. The duration of the process depends on the degree of contamination. To determine it, a specialist observes the branch pipe from which the water flows. When it becomes transparent, the procedure is stopped, and the excess liquid is drained into the drain.

- For filling The method follows the following instructions:

- They connect to the system two pipes.

- Fill the first piping with clean water and close the valve.

- Compressed air is supplied through the second one. for a third of an hour. The duration varies depending on the diameter and contamination of the pipes.

- After completing the procedure, the liquid is drained through the drain.

- The harness is washed with clean water. 3-5 times.

Before putting the heating into operation, the pipes are filled with a substance that leaves protective layerIts task is to prevent the formation of rust and scale.

Features of hydrostatic procedure in a private house

For hydraulic testing in small buildings, building codes and regulations are used. 3.05.09—62. For safety reasons it is recommended invite a specialist, which will help you make calculations and control the cleaning. It is not necessary to buy equipment for the procedure - it is enough to rent it.

Useful video

Watch the video to see how hydraulic testing is performed.

Crimping machines

A special device is used to carry out hydropneumatic flushing. They are divided into two types: manual and electric. To perform pressure testing of a residential building below 6 floors, they use a device that can develop pressure 60 barIn other cases, the use of electric ones is recommended.

Comments