Year-round heating without worries: how to easily and inexpensively install heating in a private home?

One of main systems of a private house - heating. If it stops functioning, a person will not be able to live comfortably in his home.

Therefore, it is important to choose and arrange heating in such a way that so that there are no interruptions in work. The heating system must suit the owner in quality, price and performance.

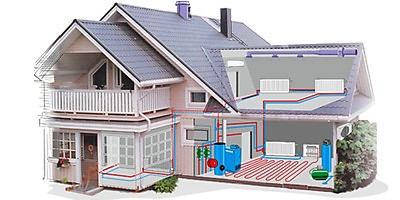

Installation of a heating system in a private house

There are several heating systems, each of which has advantages and disadvantages.

Regardless of the option chosen, everything is necessary during installation think over and calculate.

Water

More often the number of radiators is equal number of windows. Additionally, you will need shut-off and control valves, a circulation pump, and a distribution manifold.

Selecting a boiler

The choice of heating boilers is wide:

- Solid fuel — resembles stove heating, firewood and coal are used. The efficiency is not very high (75–80%), but the cost is affordable, and installation and operation are not difficult.

- Gas — an effective and reliable option when connected to the main pipeline. The advantages of gas boilers include: compactness, safety, availability, high efficiency (up to 97%)But they definitely require a chimney and ventilation.

- Electric - high performance (99%), cheap equipment and installation, ease of maintenance, widespread availability of electricity - these advantages make such a boiler very attractive to the consumer. The disadvantage is expensive electricity and the lack of necessary capacity.

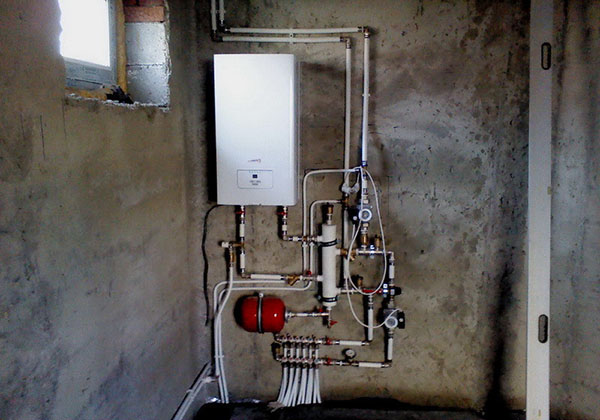

Photo 1. Electric boiler with high performance for water heating system, easy to install and operate.

- Liquid fuel — it uses diesel fuel or waste oil. This is the dirtiest fuel, it is important to remember this when cleaning the equipment. And this type of fuel is not always available. Its efficiency is high, as well as gas.

Installation methods

Water heating can be installed in two ways: one-pipe and two-pipe distribution systems.

According to the single-pipe scheme, radiators are connected consistently, one pipe is both the supply and return.

The two-pipe scheme is as follows: Heat is supplied through one pipe and returned through another.

Attention! When calculating power factors are of great importance: insulation of the house, the material from which it is built, the region of residence and other points.

First, you need to know the volume of air in the house. For one cubic meter of space, 40 Watts thermal energy. More 100 Watts added to the window, 200 — on the door.

Values for a private house multiplied by 1.5 — this is the coefficient of heat loss due to contact with the street.

For example, the volume of the room 250 m3. Let's multiply them by 40, it will work out 10 thousand watts. In the house 4 windows and 2 doors. This will add more 800 Watt required thermal energy. We obtain 10800 W. Multiply by 1.5, we get 16200 W.

This result is multiplied by a regional climate coefficient, which varies from 0.7 in the southern regions to 2.0 in the north. Let's take it approximately 1.2. 16200*1.2=19440 W. This means that the required boiler output should be around 20 kW.

Types of pipes

Pipes for water heating are made from various materials.

- Steel. They are often used, although there are many alternative options. Such pipes rust, are subject to corrosion, and require good welding for their installation.

- Copper or stainless steel. This metal is reliable and durable, but not everyone can use it due to its high cost.

- Polypropylene. The cheapest material for making pipes. It has the following disadvantages: firstly, it is difficult to make high-quality soldering at the joints, this must be done by a specialist. Secondly, polypropylene stretches during heating.

- Polyethylene or metal-plastic. It is more expensive than polypropylene, but easier to install. Pipes made of these materials are better in appearance and of higher quality, since they do not stretch.

Photo 2. Polypropylene pipes suitable for connecting a water heating system.

How to install correctly?

Steel ones need welding, copper ones are joined soldering, stainless steel pipes are installed using detachable or press fittings. Polypropylene is also bonded soldering, but this material melts when overheated, and if it is not heated enough, the connection will flow. Metal-plastic and polyethylene are connected press fittings.

Batteries can be aluminum, bimetallic, steel and cast iron. But the first two types not intended for private homes, as they are used for high-pressure heating.

Cast iron or steel radiators are much better. They are usually installed under the window, where heat loss is most significant. Connection to the pipeline is made from the side, from below or diagonally. Lateral and diagonal connection allows the battery to heat up evenly.

Installation

When installing a pipeline, the most common option is two-pipe system autonomous heating. In progress in three versions:

- dead-end scheme;

- scheme with the accompanying movement of water;

- radial distribution scheme.

When installing pipes, many factors are taken into account, so it is best to entrust this issue to specialists.

Before installation, calculations are made, then materials are purchased.

Stages of heating connection:

- boiler installation;

- installation of batteries;

- piping (starts from the device);

- connection of additional equipment;

- final connection of all elements depending on the pipe materials.

Gas

To install a gas heating system you will need a boiler, pipes, radiators, air vents, various sensors, shut-off valves and thermostatic heads.

First of all, they determine which gas to connect - mainline or liquefied.

This is important because liquefied gas is supplied in cylinders, and the main line is under high pressure is supplied through pipes.

Important! Permission is required for installation of main gas Gaztekhnadzor authorities.

Selecting a boiler

Boilers differ in several ways:

- by installation type — wall and floor;

- by functions — single-circuit and double-circuit;

- by smoke removal method - atmospheric, turbocharged, condensing.

What is the procedure?

Gas heating systems for a house are divided into natural (gravitational) and forced (with pump).

The natural system has low efficiency, since the speed of the coolant is low. The advantage of this scheme is that it does not depend on electricity.

The presence of a pump in a system with forced circulation will allow the use of pipes of a smaller diameter. The efficiency of operation increases, the heat reaches distant places.

Calculation: for heating a house it is required 0.1 m3 gas per hour. For the area 200 m3 boiler capacity 20 kW will consume energy 2 m3/hour.

Near 100 days a year the system operates at full capacity, and the same number of days at half load. Gas consumption for the cold season: 20*0.1*24=48 m3. For half load the numbers are halved - 24 m3The total heating consumption will be: (48*100)+(24*100)=7200 m3.

Pipes

The following types of pipes are used for gas heating:

- copper;

- stainless steel pipes;

- polypropylene;

- steel;

- metal-plastic pipes.

Photo 3. Metal-plastic pipes that can be installed when connecting a gas heating system.

When installing pipes, it is necessary to take into account:

- pressure power;

- system type - natural or forced;

- configuration and length of pipes;

- coolant temperature.

Connection Features

It is better to install the batteries under the window. When wall-mounted, they are hung horizontally on special brackets. The upper edge is placed 10–12 cm below the window sill. When installing the batteries on the floor, they are mounted on special legs and secured to the floor with nails or dowels.

After installing the boiler and radiators, we proceed to the installation of the pipeline. The pipes are connected to the batteries in several ways connections:

- one-sided;

- lower;

- lateral;

- saddle.

Photo 4. Heating radiator mounted under a window on a wall in a room, with lower pipe connections.

The method and order of installing pipes depends on the material from which they are made.

Connection of gas equipment has the following stages:

- Design and approval of works.

- Purchase of necessary materials.

- Cutting into the gas pipeline and connection Houses.

- Installation of boiler, radiators, pipelines.

- Test run systems.

Air

For installation you will need:

- generator or water heater;

- air humidifier;

- air ducts;

- thermostat;

- Air purification filters.

The coolant is warm air, which distributed throughout the house.

How to make heating?

There is a method for carrying out air heating two schemes - forced and gravitational.

In the first case The working fan drives the gas heated by the generator through the air ducts.

Second operates on the principle of gravity in a natural way. It does not depend on the supply of electricity, since it does not have a pump, but the heating is uneven.

To correctly calculate the power of the system, first determine what the amount of heat loss of the entire building. The power must compensate for them.

Heat loss is calculated using the formula:

Q = S*T/R, Where:

S — area of the room (m3);

T — the difference between the external and internal temperatures (°C);

R — thermal resistance of materials (this value is determined from the resistance table).

How to connect?

The installation of an air heating system should be done as follows:

- installation of a boiler and heat exchange chamber;

- connecting the fan;

- air duct layout;

- insulation and isolation pressure and intake channels;

- installation of a special hole in the wall of the house for the air intake hose.

You can assemble the heating system yourself, the connection is better trust the professionals.

First, the boiler is installed. A fan is installed under the combustion chamber, the return pipeline approaches it from behind. The heat exchanger is connected to the supply air duct from above. Then the air ducts and the return draft pipe are connected. A special valve is installed in the pipeline to regulate the air flow.

Reference! If desired, we carry out work to conceal pipes and wires in plasterboard boxes.

Useful video

From the video you can find out which heating system is best to choose for a two-story private house, how to decide on a boiler.

Test run and repair

Before putting the system into operation, it is necessary to perform a test run. This will help to identify and correct installation defects.

When the system is filled with coolant for the first time, it is necessary to monitor the operation of all devices and make repairs in a timely manner if necessary. After filling with water, release air from the radiators. Pressure check is mandatory, if it falls, add water. If everything works, the boiler is started at full power for several hours to check.