Learn the secrets of the masters: instructions for making a smokehouse with your own hands

You are viewing the section Smokehouse, located in the large section DIY construction.

Subsections: Homemade, What to make from, Components, accessories, Made of metal, Made of brick, At the dacha, For different products, Cold smoked.

A smokehouse is a device for smoking and storing food products. It is a small closed structure with ventilation, a firebox and a grate (with a brazier).

Bacteria and harmful additives are destroyed by heat treatment, this is allows products to be stored for long time.

The most common type of smokehouse is a structure with a wooden floor and a firebox made of fireproof brick material.

Content

- Operating principle, structure and general scheme of the smokehouse

- Types of smokehouses using shavings, sawdust and firewood

- DIY Smokehouse: Step-by-Step Instructions

- Materials and tools

- Preparation for manufacturing. Drawing with dimensions

- Question about the stand: buy a ready-made one or weld it yourself in the garage?

- What to make the case from

- Two ways to build a firebox. Additional function: barbecue stove.

- Time to make the lattice

- Crash Course on Making a Pallet

- How to make correct legs

- The final touch: assembling the finished smokehouse

- Final thoughts

- Useful video

- Comments (33 opinions)

Operating principle, structure and general scheme of the smokehouse

Hot smoke at temperature 300 °C condenses inside the products and gives them the desired color and aroma with a minimum content of harmful impurities.

The smokehouse consists of the following components:

- smoking camera;

- grates or hooks for product placement;

- firebox;

- thermometer (in some cases);

- chimney.

The difference between cold and hot smoking

Temperature of the smoking chamber at cold smoking makes up from 20 to 30 °CIn this range, products acquire a smoked aroma while remaining rawChicken breasts, beef, pork chops, salmon, scallops or steak are ideal for cooking this way.

Before smoking, the meat must be thoroughly processed. Cooking time depends on the amount and type of food. In some cases, after removing the food from the chamber, it is additionally brought to readiness in a frying pan or steamed.

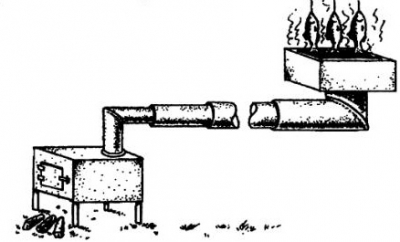

IN cold smoking structures the chamber and the firebox are connected by a chimney and are located at a distance from each other. This allows the smoke to cool as it enters the chamber.

At hot smoking Can smoke and cook food at the same time at temperature from 52 to 80 °CAfter the smoking procedure is completed, the food is served on the table.

Not recommended heat food over 85 degrees, as they can become excessively dry and unsuitable for further consumption. This method of production uses a closed type smokehouse, where the camera is located next to the hearth.

Note. Meat and animal skins it is forbidden smoke at the same time.

Types of smokehouses using shavings, sawdust and firewood

There are several types of smokehouses, each of which has its own characteristics: home, made of metal, made of brick, for the dacha, for different products, from improvised means.

Water and electric smokehouses with a water seal: round and rectangular

Water smokehouses have vertical orientationAt the bottom of the structure there is a firebox for firewood, and on top there are hooks for hanging food.

The water drain located above the firebox helps regulate the internal temperature, and the water seal does not let smoke out of it.

It is similarly structured electric a smokehouse, except that the smoke is supplied to it by means of sawdust, not charcoal.

This ensures a more stable temperature and requires less control over the smoking process. The shape and size of electric smokers do not have specific standards and vary depending on the expected amount of products and financial investment. The size varies from 30x120 to 60x240 cm.

Cylindrical homemade smokehouse from a barrel: economy class

Clean barrel with the bottom cut out Can be used as a smoker for small quantities of meat, poultry or fish.

Prepared the barrel is placed on a standoh, for convenience they are done recesses or pits for heating and kindlingSmoke is produced naturally.

In some cases, they use cement and fill it with it. foundationUse metal or wooden tubes as shelves to hold your products.

Before first use, make sure there is no moisture on the meat and that the wood is not damp.

It is recommended to use wood wood chips, sawdust or coal to start a fire. To get as much smoke as possible, add sawdust or larch wood. Install a thermometer if you want to manually control the temperature. The recommended size of the structure is 60x120 cm.

Attention! Never do not use gasoline or other means of ignition. In addition to being flammable, you risk spoiling the food with harmful fumes.

Stone or concrete large stationary smokehouses

A separate type of smokehouse is wooden structure or concrete blocks. Despite the fact that such structures the most difficult to build, they hold a lot of meat and are ideal for a large family.

They make it easier to control the temperature, which significantly reduces the fire hazard. For owners of spacious premises It is recommended to install fans in smoking devices so that the smoke can treat all the food in them.

As the walls over time are covered in soot, place food so that it does not touch the walls or ceiling.

Main elements concrete smokehouse:

- firebox;

- space for products (racks, hooks, grates);

- chimney;

- thermostat.

Elements may vary Depending on your needs, you can additionally add barbecue, storage for firewood or kitchen utensils.

The size of your smoker can be calculated based on the expected amount of meat and its weight. Recommended parameters are: 30 cm x 60 cm.

Advice. If you plan to not only cook, but also store meat in the smokehouse, pack the product carefully to prevent bacteria and insects from getting in.

Photos of interesting smokehouses: smoker steam locomotive, house, industrial cabinet, fireplace

Photo 1. A smokehouse of this design, combined with a grill, is called a smoker. The product is often shaped like a steam locomotive.

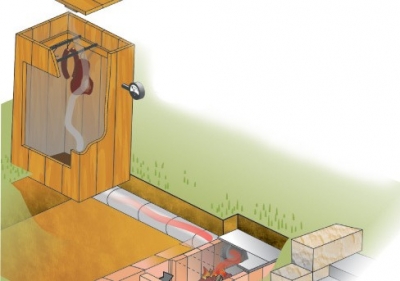

Photo 2. A stationary smokehouse can be made in the form of a small house.

Photo 3. The cabinet of the industrial smokehouse is taller than a person, which allows you to smoke many products at the same time.

Photo 4. A smokehouse can be a great addition to a fireplace. You will get a multifunctional structure.

DIY Smokehouse: Step-by-Step Instructions

It is important to remember that complex structures will cost much more, so before building, think about whether it is necessary to do large structure or is it better to do without compact version.

We will consider a project that is suitable for both lovers of small devices and those who prefer complex designs. The result will be a full-fledged smokehouse with a large area.

Main material in the project — wooden pallets, which you can buy at the warehouse of any store. In some cases, they are given away for free.

Before starting work carefully prepare the place for construction, if necessary pour the foundation.

If you decide to make a standard firebox as well, choose firebrick, as it heats up and cools down faster than red clay. It is desirable for laying buy a ready-made solution, this will save time and money.

Materials and tools

To work you will need:

- 20-30 deconstructed pallets;

- 2 screws of 1.27 cm;

- aluminum foil;

- iron flooring for roofing (not galvanized);

- pen (for the door);

- hinges.

Tools required:

- bimetallic band saw;

- drill;

- roulette;

- iron shears;

- knife;

- hacksaw;

- stapler;

- workers gloves.

Preparation for manufacturing. Drawing with dimensions

Please note the following points:

- smokehouse size;

- price materials;

- experience in construction.

The ideal size for a pallet smoker is 90x90 cmThis is enough to cook enough meat for a large family or company.

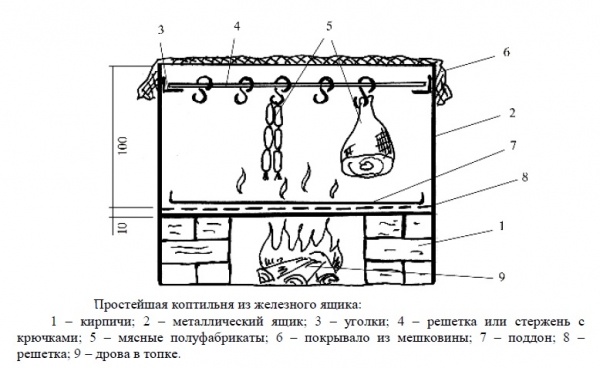

Photo 5. An example of a smokehouse drawing with dimensions and explanations. Only instead of a metal box, you can use a structure made of wooden pallets.

Question about the stand: buy a ready-made one or weld it yourself in the garage?

Use as a stand material thin metal, which is easily cut with special scissors. Be sure to measure the interior area smokehouses, so that there are no errors during further welding.

It is desirable to have at least a little experience in metalworking. Otherwise recommended buy ready-made stand in a specialty store or use hooks as holders.

What to make the case from

Assemble from pallets separately each side of the smoker. Remember that assembly is done last, when all components are ready.

The first knocked down side will serve as a reference point; measure each wall along it to avoid further skewing.

If the dimensions of the smokehouse allow build a door, leave a hole for its subsequent installation. An alternative option is the classic compact version with a firebox and a brazier.

Two ways to build a firebox. Additional function: barbecue stove.

In our project, the firebox will be a depression at the bottom of the smokehouse. As materials for the firebox, you can use firebrick or cast iron.

When using bricks Lay out two or three rows depending on the size of your smoker. Manufacturing of metal The firebox requires time and certain skills, but with it the device will serve you much longer.

Exists two options — classic firebox and a fire pit. In the first case the smokehouse will perform additional the role of barbecue, A in the second, over a pit of smoldering wood convenient for hanging meat for smoking.

Time to make the lattice

To make the grate you will need a pipe thickness about 19 mm. The thickness of the handles should not exceed 3 centimeters.

The lattice can have several tiers, but this will require much more material.

Make sure your grates are equipped with a lid, this will help prevent foreign objects from getting into the food and will significantly reduce the fire hazard.

Crash Course on Making a Pallet

Take it apart wooden pallets before assembly. It is recommended to use a bi-metal band saw, which allows you to cut the nails that hold the individual boards together.

Once your pallets are dismantled, put tags for nails and further assembly. Do not try to pull out fragments of previous nails or screws - you can damage the wood.

Important! If the wood is very strong, don't try to hammer nails into it, as splits and cracks are possible. Use a drillto make the necessary holes, then connect the boards with screws.

How to make correct legs

To make the legs you will need: stronger metal, you can buy individual parts in the store. For fastening, use either screws or a welding machine, the first option is more reliable, since in case of skew it will be possible to correct the angle of inclination.

Do not tighten the screws until you are sure that the legs are installed evenlyIf you measured everything correctly, but after fastening the legs are skewed, the problem lies in the racks themselves and they must be replaced.

The final touch: assembling the finished smokehouse

It is recommended to assemble the vertical smokehouse in the following order:

- Lay down the pallets. Make sure they are positioned evenly.

- Install the firebox and/or ignition hole fire.

- If you are using the standard stand, the next step will be its installation inside the smokehouse.

- Assemble the body from pre-knocked down walls.

- Lay the flooring as a roof.

- If necessary install hooks for smoking and the door.

Final thoughts

During construction home smokehouse start from your needs. If you plan to cook often and a lot, choose a more expensive and larger option, it will take a lot of time, but you will get a unique structure that cannot be bought in stores. A home version of the device is much more practical than a ready-made device.

Don't forget that when building a certain skill is required, otherwise you will face many difficulties and unplanned costs, as you will have to frequently replace damaged material.

But with the right approach to work, you can avoid malfunctions and save on the cost of materials, while maintaining its quality.

Useful video

A video that goes into detail homemade metal smokehouse hot smoking: preparation for work, advice on proper handling of the product, as well as drawings.

Comments

We just started it up for the first time, waited until the paint burned off, then the process went normally. But the stove bottom certainly didn't last long, the metal thickness was still small, so we replaced it with thicker iron and the smokebox bottom also had to be made of thicker iron.

You can also use old cabinets - sinks. You just need to add a drawer - a firebox at the bottom, and close the top and bottom, all in all, you can manage in a couple of hours, if you have a metal cabinet - sink, of course.