The possibilities are endless: you can even make a smokehouse out of a bucket

You are viewing the section What to make from, located in the large section Smokehouse.

Smoked products are delicacy, which most consumers love. However, store-bought products often disappoint with their imperfect taste.

In addition, smoking often uses chemical compounds that can cause serious harm to health, so it is preferable to consume these delicacies, homemade.

To do this, you can make a smokehouse with your own hands, because its production is a process not that difficult, as it seems at first glance.

To make this device, you can use wood, stainless steel sheets, metal pipe and old household appliances such as a boiler and gas stove.

Content

- Types and making of smokehouses with your own hands

- Preparation of materials and tools

- Made of wood

- From timber

- Made of plywood

- Stainless steel metal smokehouse

- From an old gas stove

- From the boiler

- From the pipe

- Advantages and disadvantages of smokehouses made from different materials

- Useful video

- Comments (3 opinions)

Types and making of smokehouses with your own hands

Before making a smokehouse, you need to decide on by smoking method products. It comes in two types - hot and cold.

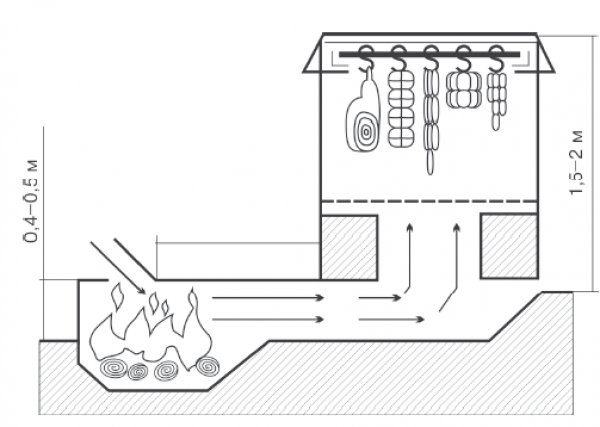

Cold smoking allows you to preserve the appearance of products and their taste. The main disadvantage of this method is that it takes a lot of time. In this case, hearth is being installed separately from the camera, in which the cooking process will take place.

One option is to dig a hole at some distance from the smokehouse, in which a fire will be built.

It is connected to the chamber by means of a chimney. The length of the chimney in this case is 2.5-3 metersIt is organized as follows: a trench is dug, depth which is 0.3 meters, A width — 0.5 meters.

Bricks are fixed along its entire length. They should fit tightly together and be fastened with cement mortar. A metal sheet is placed on top of the trench and covered with earth.

As an alternative to brick, you can use stovepipe. A damper is arranged in its upper part. It is needed to control the flame of the hearth and remove excess smoke from the product.

The smoke exhaust at the point of connection with the chamber must have diameter 200 mmIt is necessary to ensure its tightness so that the smoke enters the smokehouse.

The process of preparing the product hot smoking takes much less time than with cold. In this case, the container with shavings or sawdust is fixed directly into the open fire. The smoke from these materials during combustion should go into the chamber with the products. A container for collecting fat from the products is fixed under them. Holes are made in the chamber or a smoke exhaust is organized through which excess smoke will go away.

Once you have decided what kind of smoking chamber you need, you can start creating it.

Preparation of materials and tools

To make a smokehouse, you will need:

- materials for making a camera. This could be wooden boards, plywood, an old gas stove, etc.;

- strong reinforcement, the diameter of which should be not less than 6 mm;

- wire made of steel, for the production of gratings;

- materials to create a chimney or directly by herself pipe;

- Bulgarian with a disc for cutting metal;

- welding machine;

- nails and hammer;

- measuring roulette.

Made of wood

The smokehouse made of wood resembles miniature houseThere are walls, a door, a roof, and a chimney. Products cooked in a wooden smokehouse have a rich taste and aroma.

Manufacturing of the case

The smokehouse body is made as follows:

- The frame of the device is a rectangular structure, height which is 2 meters, A width 1 meterIt is assembled from beams.

- Frame from three sides It is finished with boards that fit tightly against each other.

- On the fourth side a board is installed, also knocked together from boards. It should close tightly without any openings.

- It's being put together roof with a hole for a tubeIf there is none, then it is simply done window, so that it can be opened and closed at any time. After that, the roof is fixed to the structure.

- Inside the structure are organized grooves for tray and grateFor the tray, the grooves are made at the bottom of the structure, for the grate - in the middle.

Important! If gaps form between the boards, then this is will have a negative impact on the quality of the product. The gaps need to be sealed with tow.

How to make a lattice

To make the grate you will need unpainted wire with a diameter of 5-6 mm. It is performed from it frame, the size of which corresponds to the internal size of the smokehouse. Pieces of wire with a diameter of 3 mmThe distance between them is — 2 cmAll parts of the grille are welded together.

A tray is made from a metal sheet. Its size corresponds to the size of the grate, as well as the internal size of the smokehouse.

Smoke exhaust

The smoke exhaust is carried out as follows:

- It is being dug out trench, the length of which is 2.5-3 m, width - 0.5 m, depth - 0.3 m.

- The trench is being laid out brick, which are connected to each other cement mortar.

- On the brick the metal sheet is fixed.

- Above the earth is being filled up, layer in 15 cmso that the chimney does not freeze in winter.

Assembly

It is being dug out pit, corresponding to the dimensions of the smokehouse. Its depth is 40 cm. It is placed on the bottom of the foundation crushed stone, concrete blocks are fixed along the walls using reinforcement. Then all this is filled with concrete mortar. It is installed on the foundation camera, inside which a tray for collecting fat from food and a grate should already be installed.

Attention! The assembly of the smokehouse begins with the arrangement of the foundation for it.

To the foundation the chimney is being installed. An iron angle welded from a metal sheet is fixed at one end. Its size must correspond to the dimensions of the chamber. It is installed on the foundation. At the other end of the flue, a firebox. It should be made of firebrick and equipped with a metal door. This will be the place where the fire is made.

The final stage is the installation of the smokehouse. It is fixed directly to the foundation. Two structures are fastened together using metal brackets. The device is ready for use.

Photo 1. Possible drawing of a wooden smokehouse with the indicated dimensions. Arrows indicate the direction of smoke movement.

From timber

A log smokehouse is made in the same way as a wooden smokehouse, but here, instead of boards, the body is made entirely of beams.

Manufacturing of the case

The body of the smokehouse is made of beams, 1.3-1.5 m long and 20x50 or 50x50 mm cross-section. The frame of the device is formed from them. It is a rectangular box. Then it from three sides is covered with boards, section 20x150 or 25x150.

When making a frame from beams, you need to decide on roof construction. If a gable roof is assumed, then guides are made from bars, which represent an isosceles triangle. A median is made from the vertex to the base.

Then it is done doorway. Boards are nailed, 20 cm long at the top and bottom. A door is fixed in the opening, a roof with a hole for the pipe is installed on top. After that, the body of the smokehouse is covered with clapboard. A metal sheet is laid on the roof, the hole for the pipe is not closed.

Inside the smokehouse, they are formed grooves for fixing the grate and trayFor this purpose, boards are used, the length of which is 90 cm. By using screws They are screwed onto the sides of the camera.

How to make a lattice

The grate is made from unpainted wire. First, a frame is made, the dimensions of which correspond to the dimensions of the interior space of the chamber. Wires are welded to it at a distance of 4 cm from each other. The grate is ready.

The tray for collecting fat from products that flows out of the products during smoking is made of a metal sheet. Its dimensions correspond to the dimensions of the grate.

Smoke exhaust

To make a chimney, you need to dig a three-meter trench between the fireplace and the smoking chamber, width - 0.5 m, depth - 0.3 m. It is installed in it. stovepipe, which is filled with concrete mortar. A layer of earth is poured on top, the thickness of not less than 15 cmThis will prevent the flue from freezing even in winter.

Photo 2. The smoke exhaust from the old chimney leads to a place prepared for the firebox. Thanks to the firebrick, it is quite safe to make an open fire there.

Assembly

Before installing a smokehouse on the site, a foundation is made for it. For this, a hole is dug pit, corresponding to the dimensions of the smokehouse, with a depth of 40 cm. The bottom of the foundation is covered crushed stone, concrete blocks are fixed along the walls using reinforcement, after which the entire pit is filled with a solution made of cement. On it the camera is fixed. Inside of which there should already be a tray installed to collect fat released from the products during smoking, and a grate.

To the foundation the chimney is being installed. An iron angle welded from a metal sheet is fixed at one end. Its size must correspond to the dimensions of the chamber. It is installed on the foundation. At the other end of the flue, a firebox. It should be made of firebrick and equipped with a metal door. This will be the place where the fire is made.

The final stage is the installation of the smokehouse. It is placed directly on the foundation. The two structures are fastened together. using metal brackets. The smokehouse is ready!

Made of plywood

The smokehouse is made in the same way as from wood, but here plywood is used for its lining. The disadvantage of such a device is low thermal conductivity.

Reference. To make a plywood smokehouse retain heat better, it is enough to make the walls in several layers and cover the structure clapboard.

Stainless steel metal smokehouse

The main advantages of a stainless steel smokehouse are: long service life And safety use. Its size depends on the user's needs for smoked products. To provide a small family with delicacies, a compact rectangular device will be enough. To supply a large family with smoked products, the smokehouse must be of impressive size.

Manufacturing of the case

To make the body of the device, you will need sheets of food-grade stainless steel, such as: AISI 304If you use an old barbecue made of the same metal as a base, all that remains is to close the extra holes, make a lid and grooves.

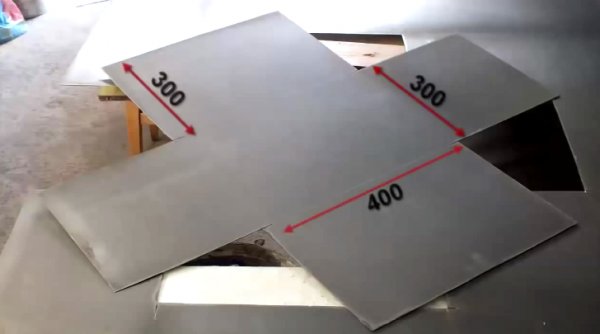

Photo 3. A shape cut from sheet metal measuring 300x300x400 is quite suitable for the body of the smokehouse.

Algorithm for making a smokehouse:

- Sheets of material are being cut, in accordance with the selected device dimensions.

- Details are welded among themselves.

- Inside the case the grooves are fixed for a grate or grates.

- From steel sheets the lid is being made, equipped with a handle and a small hole for smoke to escape.

- Under the lid inside the device grooves are made for water.

How to make a lattice

The grate is made of unpainted wire. A frame is made from it, the size of which corresponds to the internal size of the smokehouse. Pieces of wire are fixed to the frame. at a distance of 4 cm from each other. All parts of the grate are welded together.

Smoke exhaust

The smoke exhaust in this case not organizedThe only thing that is done is a hole in the lid.

Assembly

A tray with sawdust is placed inside the smokehouse, a tray for collecting fat from products is fixed on it, a grate or grates are installed on the grooves. The grooves are filled with water. Such a smokehouse is placed on an open fire.

For this purpose, a hole is dug, 40 cm deep. Its width and length should correspond to the dimensions of the smokehouse. Then it is lined with firebrick. Then the fuel is placed here, lit and the smokehouse is installed. It can be used even in an apartment. For this, the device is placed on the stove and left to cook the products.

From an old gas stove

An old gas stove can be used to create a smokehouse. To make the device, in this case, you will need minimum time and effort.

Manufacturing of the case

An old gas stove is ready smokehouse body. There are grooves for the grate and the baking tray, the grate itself and the baking tray for collecting fat from the products, as well as the necessary thermal insulation and seals to ensure tightness.

How to make a lattice

To make grates for such a smokehouse won't have to, since they are already in stock.

Smoke exhaust

To organize the smoke exhaust, holes are drilled on the side walls of the stove 2-4 holesTheir diameter should be 10-15 mm. The same holes are made on the side walls at the top of the stove. Thanks to this, smoke will be removed both from below and from above the structure.

Assembly

From the design the gas oven burner is removed. Instead, fuel for open fire. A baking tray with sawdust is placed on it. A baking tray for collecting fat from products is fixed on top. A grate is inserted into the center of the stove, on which products will be cooked. The device is ready for use.

Photo 3. The smokehouse from the old oven has already been used more than once - traces of soot on the surface confirm this.

From the boiler

There is no need to rush to throw away the old boiler. Its body is suitable for creating a smokehouse.

Manufacturing of the case

The first thing to do is the lids are sawed off devices. After this, the inner tank is removed. In the outer tank, a hole with a door is cut out, like a damper on a stove. To it the barrel is welded without a bottom and an external tank. This is necessary to create thermal insulation. At the bottom of the structure, above the opening with the door, grooves are organized for trays, and in the middle - for the grate.

How to make a lattice

Unpainted wire is used to make the grating. A frame is made from it, the size of which corresponds to the internal size of the structure. Pieces of wire are welded to the frame at a distance of 4 cm from each other.

Trays for sawdust and fat from food are cut out of a metal sheet. It should be the same size as the grate.

Smoke exhaust

The smoke exhaust here is open top constructions.

Assembly

The structure is placed on a metal sheet, down the hole with a door. There will be an open fire here. A tray with chips or sawdust is installed on the first groove, and a tray for collecting fat from products is installed on the second. A grate for products is fixed in the center. After that, you can start smoking.

From the pipe

Even from a simple metal pipe you can make a smokehouse.

Manufacturing of the case

To make the body, you will need a metal pipe, diameter 300 mm, door hinges, metal corners, handle, hook and metal sheets. The principle of making a smokehouse:

- From the sheets 2 bodies are cut out, the size of which is equal to the diameter of the pipe section. A small hole is made on one sheet, after which it welded to one side of the pipe. On another disk the loop, handles and hook are fixed. Using a loop, the sheet is secured to the other side of the pipe. This will be lid smokehouses.

- Inside constructions corners are welded. They will serve as guides for the location of the tray where the fat drains, as well as the grate for the products.

- Down pipes corners are welded, which will become her legs.

How to make a lattice

?

?

Unpainted wire is used to make the grating.

A frame is made from it, the size of which corresponds to the internal section of the pipe. Wire pieces are welded to the frame. at a distance of 4 cm from each other.

A tray for collecting fat from food products is cut out of a metal sheet and is the same size as the grill.

Smoke exhaust

The only flue gas outlet in such a design will be hole in the lid or on a welded sheet.

Assembly

Sawdust or other smoking material is placed at the very bottom of the smokehouse. After that, a tray and a grate are placed on the corners. The structure itself is placed to the hearth of the fireAfter this, it can be used for its intended purpose.

Advantages and disadvantages of smokehouses made from different materials

?

?

Each smokehouse discussed above has its own advantages and disadvantages.

So, in the design made of wood, beams or plywood you can cook food using this method hot and cold smoked. This is the main advantage of the smokehouse. The disadvantages include the fact that the materials presented have short service life.

The advantage of the design made of stainless steel is that she simple in manufacturing and transportable. It can be used both in a private house and in an apartment. Another advantage of such a smokehouse is long service life.

Disadvantage - you can cook food only by hot smoking.

Smokehouse from an old gas stove do easier total. Here all the details are already done. Another plus is that it can be used both in an apartment and in a summer house. The design has long service life, but you can cook food here only by hot smokingThis is the main drawback of the device.

The main advantages of the smokehouse from the boiler and pipe is long shelf life. Flaw - impossibility of cold smoking products.

Making a smokehouse from scrap materials is a piece of cake not at all complicatedThe process takes little time and does not require much effort, and the finished product will last for many years, delighting you with delicious smoked delicacies.

Useful video

Check out this video that shows you how to make a makeshift smoker out of foil.

Or he's just a fishing enthusiast and catches the fish himself. Then it's a completely different matter.

And the dimensions of such a chamber, in my opinion, can be made any. Everything will depend on the power and performance of the smoke generator.

And such a setup will be quite profitable for small-scale production, even if you use purchased fish. The cost of smoked fish is still higher, and it is easier to sell