Safety and beauty: how to finish a sauna stove with decorative materials

You are viewing the section Finishing, located in the large section For the bath.

In most cases, finishing of sauna stoves is done in order to give the structure an attractive appearance.

But the decorative facing elements of the device can act as a heat screen, which provides reliable protection against infrared radiation, and also allows you to maintain heat in the bathhouse for a long time.

Heat resistance and high resistance of facing materials to mechanical damage significantly extend the service life sauna stove, and make staying in the steam room pleasant and safe.

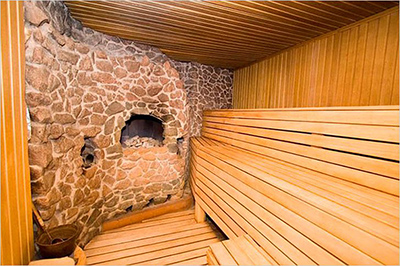

Options and features of finishing various elements of the sauna stove: photo

To begin the design, it is necessary to take into account not only the appearance of the future structure, but also the technical characteristics of the facing materials, which have good heat resistance and the conductivity of the heat emanating from the furnace.

Photo 1. A sauna stove lined with ceramic firebricks, one of the most common materials.

Various methods of finishing homemade sauna stoves involve lining the finished frame of the stove structure with materials such as:

- tiled or clinker tile;

- red, fireclay or ceramic firebrick;

- natural or artificial types of stone;

Photo 2. A sauna stove, the frame of which is lined with ordinary light-colored ceramic tiles.

- high strength steel cases;

- plaster clay based;

- beautiful but expensive tiles.

Each finishing material finds its application in facing any elements of sauna stoves and, of course, has its own characteristics that need to be taken into account during the work process.

Photo 3. A sauna stove with beautiful cladding - tiled finishing material, which is considered the most expensive.

Wall cladding of the structure

The simplest finishing option is plastering. But it can only be done on a brick surface. The stove must be built from this material or lined with it.

When tiling walls, this feature should also be taken into account, because the finishing involves fixing tiles only to a brick base using heat-resistant mixtures, which will prevent tiles from falling off and cracking.

Brick and stone – the most popular methods of finishing furnace structures made of cast iron and metal.

The cladding with these materials is carried out at a distance 10-15 centimeters from the frame of the stove and provides for the presence of lower and upper openings for free air circulation. Finishing is usually carried out to the level of the stones.

Firebox of a sauna stove

The firebox is one of the most noticeable elements and, of course, should complement interior style.

In retail chains you can choose a door for the firebox of the desired design and various models, but the furnace portal is now being designed manually, for this purpose they use materials that are used in the decoration of the room or the stove itself.

If the firebox portal is located in the steam room, it is made in the style of the stove. If the firebox portal is taken out to another room, it should match the design of the room and contain the same finishing materials.

Chimney

The chimneys of the stoves located in the steam room are exposed to high temperatures, which sometimes amount to 500 degrees.

Chimney structures made of metal can be lined heat-resistant types of bricks, after which, at the owner’s request, finishing can be done with tiles, plaster or patterned tiles.

The place where the chimney enters the ceiling is closed basalt, asbestos sheet, as well as a sheet made of metalThe metal sheet is usually placed above the stove and covers its dimensions several times.

Important! Many elements of sauna stoves are characterized by increased fire hazard, being in close proximity to wooden structures of the room, therefore, when facing them, special attention must be paid installation of thermal insulation materials.

Properties and features of using materials for finishing a homemade device

Each finishing material has certain properties of heat transfer, heat resistance and differs in the degree of safety when used. Among such materials there are the cheapest, the most popular and the most expensive, which are selected according to the tastes and desires of the owner.

Brick

A common and popular type of facing material for cast iron and metal structures.

Despite the longer heating time compared to metal, brick remains stable for a long time keeps warm and has excellent resistance to moisture.

Uniform heating of the structure provides a half-brick lining of the stove over the entire height of the metal body, with holes provided in the masonry for air circulation. In places where the doors are located, the upper part of the hole is reinforced with corners.

Dye

Painting is the simplest and most accessible method of finishing a sauna stove, which can be done on any surface, but it is necessary to take into account the heat resistance of the paint, the ability of the coloring material withstand very high temperatures. Regular oil and most enamels are not suitable for this purpose, they quickly crack on the surface expanding from heating, peel off and burn out.

When painting the interior of a bathhouse, you should also consider the moisture resistance of the paints, the structure of which will not be destroyed by a large amount of steam. The basis for the production of such paints and varnishes is silicone and silicon included in the composition. Similar types of paint include popular KO-8101, KO-8111, KO-8222, heat-resistant "Certa" OS-82-03T.

To paint with heat-resistant and moisture-resistant enamel, the surface is cleaned with sandpaper and degreased with solvents, after which they begin painting the stove.

Stone

?

?

Finishing stove structures with natural or artificial stone is also very popular.

The structure of natural stones contains minerals that are distinguished by their healing properties and healing natural power, and artificial stone is popular due to its availability and attractive appearance.

Both materials have excellent thermal conductivity, retain heat for a long time, are durable and are successfully used for lining sauna stoves.

The stone finishing is carried out on the installed steel mesh, under which the basalt fireproof cardboard, which helps to soften the heat from metal structures.

The cladding is done in various ways using solutions resistant to high temperatures. Natural stones are pre-soaked in water for better bonding.

Tile

Ceramic or clinker tiles are a traditional material for cladding. Their properties in terms of heat transfer and heat resistance are similar to brick, so the material laid on the mortar does not crack due to thermal expansion.

In places of particularly strong heating, tiles are laid on silicone heat-resistant sealants, which are applied along the edges of the corners, as well as in the center of the tile.

Between each tile a space is maintained gap for possible thermal expansion, which is subsequently filled with heat-resistant grout.

Reference! The category of tile material also includes finishing with eye-catching, expensive tiles of various shapes and colors. This type of cladding not only has all the characteristics inherent in tiles, but also creates amazing beauty in the interior of a Russian bathhouse.

Steel case

A steel case involves installing a rectangular, square or cylindrical metal frame around the stove on a heat-insulating base. The cases are distinguished by good heat transfer, perfectly retain heat and maintain an optimal temperature level in the room.

Metal cladding is durable and can be easily painted with heat- and moisture-resistant paints, but, just like a metal stove, it gets very hot and becomes unsafe if touched carelessly.

Plaster

Since ancient times very popular and a well-known type of finishing for sauna stoves. The composition of plaster solutions includes various materials in a variety of combinations. The basis for the mixture is:

- clay;

- sand;

- fireclay;

- asbestos;

- gypsum;

- lime;

- cement;

- fiberglass;

- small straw;

- salt;

- water.

The plastering is done on the brick surface on a fiberglass mesh reinforced around the perimeter of the stove and has good thermal conductivity and heat resistance.

Important! The plastered surface is susceptible to whitewashing, painting, is safe to touch, but requires systematic annual care.

Useful video

The video shows how to clad a sauna stove with bricks.

Choice of cladding

Finishing methods differ significantly from each other. In most cases, the choice of the design cladding option depends on the availability of materials and financial capabilities.

For example, installation of a three-layer ceramic chimney that does not require finishing is possible, but this product is not manufactured in the Russian Federation.

Likewise, not all regions of the country have the opportunity to purchase the natural stone needed for cladding.

The option with a brick finish of the stove is the most popular Today, many types of facing ceramic bricks not only have a variety of colors and shapes, but also do not differ in their structure from refractory heat-resistant analogues.

Comments