1300 degrees and not the limit. Making an amazing muffle furnace with your own hands

You are viewing the section Muffle, located in the large section Types of furnaces.

In production Muffle furnaces are used for growing single crystals, firing ceramics, melting and refining various metals, and conducting analyses.

Stoves, created independently in home workshops, used for drying ceramic products, working with molten glass, gold and silver.

Content

Schemes of muffle furnaces and features of their designs

Russian and foreign manufacturers offer dozens of models muffle furnaces, differing in power, working chamber size, muffle heating methods, network voltage requirements, design and cost.

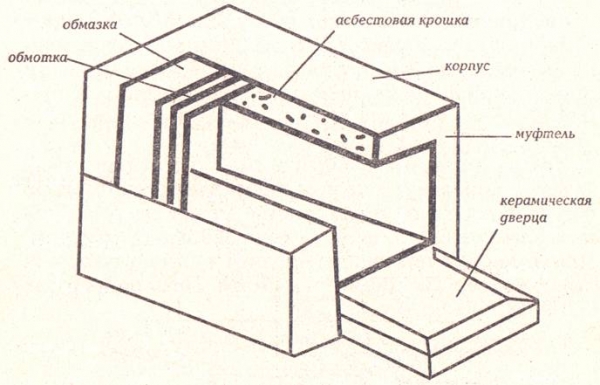

Photo 1. Schematic diagram of the main element of a high-temperature furnace — the muffle. The main parts of the structure are indicated.

Electric stove

In electric muffle furnaces, heating occurs using elements, powered by the mains. Devices consist of the following parts:

- from a case with a door;

- from an outer layer of cladding made of non-combustible porous material;

- from an inner lining layer made of hard refractory material;

- from heating elements and a network connection system.

Frame welded from sheet steel or use a ready-made casing from old equipment (from an electric or gas oven, refrigerator, steel barrel). The larger the casing, the larger the working chamber.

They are facing the body is made of basalt wool (mineral wool) or asbestos fiber, perlite, vermiculite. These heat-resistant materials retain heat well.

Refractory layer of fireclay bricks withstands temperatures of 1300-1850 degrees. A paste of fireclay (kaolin) clay and fireclay sand is used to attach the bricks. A hard refractory layer is sometimes made from a thick layer of fireclay without using bricks.

Heating elements, thermostat, etc. electrical equipment can be purchased in electrical goods departments. On sale are spirals, wire and tapes made of nichrome, fechral, infrared emitters (ceramic and quartz).

They install it on the door lock, preventing it from opening accidentally. A heat-resistant lining is attached to the inside of the door.

Gas device

Gas muffle furnaces not for sale, since there are no technical regulations for connecting a burner to them. The use of gas from cylinders is possible only in factory gas stoves and heating columns.

The craftsmen use standard equipment from a gas stove or homemade burners. Into the design gas roasting appliance enter:

- steel body;

- a layer of porous thermal insulating material;

- fireproof hard layer;

- a ceramic container for firing products, inserted into the furnace (muffle);

- gas burner;

- gas supply tubes;

- Furnace cover reinforced with refractory material.

Frame made from a barrel or an old oven. It is fixed on racks (not on the floor). The section of the body can be round, rectangular, square. The lid They are made of steel and lined with basalt wool and a layer of mortar.

Porous thermal insulation sealant created from expanded vermiculite, asbestos fiber, mineral (basalt) wool or perlite.

As refractory Fireclay bricks are most often chosen. They are bonded with mortar or clay-fireclay mortar.

Reference. A hole for the burner is cut in the wall or bottom of the housing.

Suitable for a small oven burner from household gas equipment, which has gas supply control valves. For large devices, craftsmen use burners of their own making, which are not safe.

Advice. To allow gases to escape from the oven, openings are created at the edges of the lid or at the edges of the tank. small holesTheir size is regulated by covering them with pieces of basalt wool.

IN as an internal container, in which the fired items are placed, a factory-made ceramic vessel is used (in very small kilns - a flower pot). If there is no ready-made container, one can be ordered from the potter.

How to make a muffle furnace on gas

Making your own device includes the following steps:

- creation (purchase) steel body and installing it on supports;

- cutout mounting holes burners and gas outlets;

- laying and fixing porous thermal insulator on the walls and bottom of the oven;

- cladding fireclay brick ovens;

- drying device;

- installation gas equipment;

- manufacturing or purchasing muffle;

- manufacturing lids made of steel sheet and fireclay.

When starting the structure, the burner is turned on at low power, and the flame is gradually increased. Warm-up time on average is 40 minutes, time roasting on a strong flame - 1-1.5 hours.

Fusing furnace

Muffle furnaces for fusing, designed for sintering pieces of glass, create a working temperature up to 600-1100 degreesAt lower temperatures, glass simply softens, allowing it to be bent.

The main difference between fusing furnaces and conventional muffle electric devices is in use as a refractory only mineral wool and other porous materials.

The muffle is heated not an open spiral, but special elements in quartz tubes, which prevents scale from getting onto the products. The heaters are located in the side walls or in the upper part of the chamber.

The fusing temperature is set by a temperature controller. Heated glass is a viscous and fluid material, so fusing furnaces installed strictly horizontally (using a building level).

When making a fusing furnace yourself It is essential to use a thermostat and closed heating elements. Mineral wool is chosen as a refractory. Otherwise, the device is no different from an electric furnace with a brick muffle.

Induction muffle furnace

In such devices, the metal melts under the influence of high temperatures, which are created when passing electric current through a solenoid or core (inductor).

The heated body plays the role of a secondary winding. Muffle induction devices warm up in a few seconds.

There are different options creating an induction furnace at home. In the simplest case, use a copper rod for the spiral, a welding inverter (electric generator), control and measuring equipment, wires, terminals for connecting them.

Making an Electric Muffle Furnace with Your Own Hands

Let's consider the construction of a small muffle furnace. The device will be connected to a network with voltage 220 V.

Selection of materials

The materials for making the device are available in hardware stores and electrical supply departments. To create a muffle furnace, you will need:

- leafy steel thickness 2-3 mm (2 sq. m);

- rolled steel with a "corner" section (3 m);

- heat insulating material (basalt wool);

- fireclay brick, 12 pieces;

- mortar (5-7 kg);

- thermocouple chromel-alumel;

- ceramic tube for thermocouple;

- spiral nichrome;

- fiberglass tubes for insulation of the leads of the coil and thermocouple.

When choosing materials, they are guided by their quality: heat resistance, ability to withstand rapid heating and cooling. In order for the muffle to serve for a long time, you should not take a brick that has been in use for several years.

Preparing the tools

To prepare a paste from mortar You will need a ten-liter bucket and a mixer. When mixing the solution, use a respirator. The following will be required for installation construction tools and equipment:

- welding machine;

- electric drill;

- Bulgarian;

- set of carbide and metal drills;

- stove-maker's tools: hammer-pick, trowel, small spatula, measuring tape;

- Electrician's tools: pliers, nippers, round-nose pliers, metal ruler, regular and Phillips screwdriver.

Step by step instructions

The workflow includes next steps.

- Mark and cut steel sheet. Cut out the casing parts and door parts.

- The casing is welded and the door.

- They are welding to the body hinges for the door and lock mounting.

- From mortar make a solution (according to the instructions on the package).

- From bricks they are putting together a model of the stove, determining where the spiral will be laid.

- In bricks grooves are made with a drill for laying the spiral. A carbide drill is used for the work.

- Corner the profile is cut with a grinder and welded from it the frame for the bricks.

- In the frame laying a muffle of bricks (on a mortar solution).

- Masonry dry for 3-4 days.

- In the walls of the muffle in the grooves laying a nichrome spiral. Having drilled a hole in the bricks, the contacts are brought out.

- On the thermocouple put on a ceramic tube and fiberglass protection.

- They make it in a muffle with a carbide drill hole for the thermocouple and insert her inside the chamber.

- Contact Output Locations coated with mortar solution.

- Muffle dry for 1-2 days.

- On the back wall of the casing lay a layer of mineral wool.

- In the casing install a muffle. It is placed on a metal grate-stand so that the heavy stove does not compress the layer of cotton wool underneath it.

- With a metal drill in a casing drill holes, bring the contacts of the coil and thermocouple outside.

- The gap between the muffle and the casing is tight stuffed with basalt wool.

- Layer basalt wool is placed in the door and fasten with nichrome wire.

- The door installed on the casing, they put a lock.

- They are sawing out a piece of fireclay brick the size of the doorDuring firing, it is placed in the muffle in front of the door.

Important! To prevent the spiral from falling out of the grooves made in the brick, it is placed in several places strengthened with mortar solution.

How to properly connect a muffle furnace to a power source

If you have no experience working with electrical appliances, it is better to contact a professional electrician. To connect the device to the network need to purchase:

- thermostat;

- large terminal block made of heat-resistant plastic;

- small terminal blocks made of heat-resistant plastic for splicing wires;

- contactor (electromagnetic starter);

- two-wire electric cable;

- electrical plug;

- standard electrical panel casing.

For this oven selected single-channel thermostat M-1-K, which regulates the temperature of the working chamber up to 1300 degreesThe device is capable of operating on a complex schedule, with its help you set the time and temperature of heating.

Reference. The cross-section of the nichrome wire and its length, the diameter of the spiral turn, the cross-section of the connecting wires and other parameters of the electrical circuit calculate according to reference books and choose in advance.

The element has 7 connection sockets (two terminals for power wires, two for connecting a thermocouple, three for a relay)The device is controlled by four buttons. When the thermostat is on, the indicator light is on. The device comes with two brackets for mounting in the panel and detailed instructions for connection.

Installation of the block

The block is being installed in the following order.

- The thermocouple and coil contacts are insulated with terminal blocks. connect with two-wire wires.

- To the power cord connect the plug.

- In the shield they are fastening thermostat, contactor and large terminal block.

- To the thermostat via a contactor and terminal block connect the thermocouple, muffle coil, power cord with plug.

An electric muffle furnace is a must are grounded.

Possible difficulties and problems when creating a furnace

Difficulties arise when manufacturing the device with selection of material And installation of a temperature control system. Incorrectly selected materials lead to rapid destruction of the muffle. Thus, some craftsmen, in order to save money, use low-quality bricks, clay-sand mortar instead of fireclay. This leads to cracks in the muffle and loss of heat.

Cracked muffle temporarily sealed with a solution of fireclay clay. The chamber must be removed and replaced with a new one.

If you bake connect to the network without a thermostat, the temperature in the muffle is not controlled. This leads to damage to products that require firing at a given temperature. To solve the problem, you should purchase a thermostat and electrical equipment, assemble the control unit and connect it to the heating elements of the muffle.

Useful video

Check out the video that shows how to start making a muffle furnace: what materials and tools are required, what needs to be done first, and what actions are not recommended.

How to check the safety and reliability of a homemade stove

To check the reliability of the muffle furnace, it is tested. During the test switching on, the device tested at low temperatures, then at maximum temperature. When operating the device indoors circuit breakers should not trip. This indicates that the electrical equipment is not connected correctly.