Easy to make, convenient to use. A muffle furnace for firing ceramics is a master's dream!

Firing is a process of exposing products to high temperatures, which changes physical and chemical properties materials.

During firing, water evaporates, chemical reactions occur, and amorphous minerals dissolve and crystallize. The technology is applied to increase density, strength products and changes in their appearance.

Content

What should be taken into account when choosing a ready-made muffle furnace?

When choosing a factory muffle furnace take into account the type and composition fired products. Factory furnaces allow you to set a wide range of temperatures and set the firing time.

The choice is influenced by:

- type of materials to be fired;

- volume of products to be fired.

Materials processed: clay, porcelain, earthenware, stone

Materials for firing at its core contain clays. The following are fired in muffle furnaces:

- red clay (pottery and decorative items);

- terracotta (decorative interior elements, sculpture, tiles);

- fireclay (pottery, decorative crafts for interiors);

- porcelain figurines, dishes;

- products from stone mass;

- faience products.

The firing is carried out in one, two or three stagesThe number of stages increases if glaze and painting are applied to the surface of the products.

Red clay and terracotta burn at a temperature 900-1100 degrees. First (waste) roasting is carried out at 900-960 degrees. Temperature second (watered) and third firing depends on the characteristics of the enamel and paint.

Porcelain and stone masses during the first firing they heat up up to 800-1000 degrees. Temperature second and third firing within 1250-1420 degrees and depends on the technical parameters of paints and glazes.

Faience first processed at temperature 1200-1250 degrees. Temperature second-third firings - 900-1250 degrees.

Fireclay ceramics and pottery are fired at a temperature 1350-1400 degrees (utility firing). Glazing and decorating are carried out at a temperature of 900 degrees.

Volume of products

The volume of products has a decisive influence on the choice of the finished device. There are models on sale with front and top loading, the volumes of their working chambers vary greatly.

For firing small items produced in small series, a compact muffle electric furnace is suitable. PM-8 (manufacturer JSC "Elektropribor", Russia). The size of the working chamber is 19x12x30 cm, the maximum volume of products for firing is 0.0068 cubic meters.

A muffle electric furnace from a Russian manufacturer is suitable for firing large ceramic products. JSC "Nakal", model PC-1000/14. Internal dimensions of the muffle — 160x78x78 cmThe chamber allows firing products with a total volume 0.97 cubic meters.

For firing items up to 0.064 cubic meters, a muffle electric furnace from a German manufacturer will do Well, model WF-35 (internal size of the muffle 40x40x40 cm).

Photo 1. Muffle furnace WF-35 from the manufacturer Welte (Germany). The working chamber with heating elements is visible.

The maximum number of products is usually loaded into the chamber in order to use the entire working volume of the muffle. If the products are not produced constantly, in small series, souvenirs have small dimensions, it is enough to purchase a furnace with a compact working chamber. If the products large volume (or the master creates small items in large series), you should choose a unit with a spacious firing chamber.

Reference. When loading, take into account coefficients of linear expansion each type of ceramics.

Description of high temperature ceramic kilns

Muffle furnaces for firing ceramic products operate on gas and electricity. Induction ovens for this purpose do not use.

Electrical devices

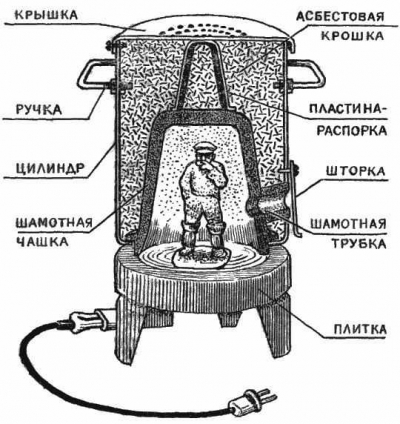

Electric ovens operate from the mains 220 And 380 voltsThe unit consists of the following elements:

- from muffle (thick-walled chamber made of refractory material);

- made of heat-resistant cladding muffle;

- made of metal corps;

- made of metal doors with heat-resistant insulation;

- from heating elements;

- from temperature control devices.

The body of the factory muffle furnace is made of steel. Amateur craftsmen often use metal casings for electrical appliances.

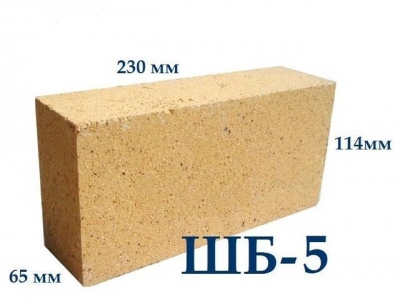

The muffle is laid out from refractory (fireclay) bricksA ready-made fireclay-sand mixture, mortar, is used as a binding solution.

Thermal insulator (basalt mineral wool, fluffed asbestos) are stuffed between the body and the muffle. Good heat insulators are perlite and expanded vermiculite.

The heating elements in this version are: nichrome or fechral coils, infrared heaters. Important devices for setting the desired temperature are the thermostat and relay.

The door of the muffle furnace is firmly pressed against the body with the help of castleOn its inner side a layer of mineral wool and a plate of fireclay brick are attached.

Gas ovens

In gas muffle furnaces the chamber is heated by gas from a household gas cylinderGas is used as a heater. burner from domestic stoves or ovens.

The body of the gas muffle device is made of metal. It can have a square or round cross-section. Hobbyists use as a body steel tanks, welded Sheet steel boxes.

Heat-resistant cladding is made of rolled basalt wool, vermiculite, asbestos fiber, perlite. The cladding is attached to ceramic fasteners, nichrome wire.

Heat-resistant cladding is laid fireclay firebricks. The masonry is done using fireclay mortar or mortar.

Gas burner is attached to the bottom of the case or to the side of the camera. It does not provide uniform heating, therefore the firing is carried out in another muffle, which is inserted from above into the chamber. The fired items are placed in it.

The lid is reinforced a thick layer of loose heat insulator and fireclay. Furnace gases escape through special cracks or gaps between the lid and the body.

Making a muffle electric furnace with your own hands

Before starting work, select materials, devices, electrical equipment. The oven is connected to the household electrical network.

Selection of materials

The oven of this model is compact, its production does not require special materials and parts. For work you will need:

- mortar (ready mix) - packaging 5 kg;

- leafy steel thickness 3 mm (2.2 sq. m);

- fireclay bricks 16 pieces;

- mineral wool roll (basalt);

- fiberglass tube, ceramics (diameter 10 mm, length -15 cm);

- rolled steel corner section - 3 m;

- spiral (fechral, nichrome) for electric stove (1.6 m);

- thermocouple.

Important! Used materials and electrical equipment components, do not guarantee normal operation electric furnaces.

Preparation of tools and equipment

To lay the muffle you will need: stove maker's tools (trowel, spatula, tape measure). To work, you need to buy or rent equipment and tools:

- electrical drill and drill bits;

- grinder for cutting metal and brick, set of discs;

- arc welding machine and electrodes;

- ruler, square;

- Electrician's tool (screwdrivers, large and small pliers, round-nose pliers, side cutters, nippers).

Step by step instructions

Before starting work, mix the masonry mortar. Construction of an electric furnace includes the following stages:

- Sheet steel is marked, draw lines using a pencil, ruler and square, then use a grinder cut out the details casing and door.

- With a welding machine weld the casing.

- To the casing weld the door mounts. A lock is welded onto the door.

- Grooves are cut into the bricks with a carbide drill (under the spiral).

- From corner profile weld the frame (for muffle chamber).

- In the frame lay out the muffle (chamber), fastening the bricks with mortar.

- Camera dried for 5-6 days.

- Carefully into the grooves lay the heating coil, the ends are brought out beyond the muffle through a pre-drilled hole.

- Spiral in 3-4 places they are fixed solution.

- Through the hole into the muffle chamber insert a thermocouple, the contacts are protected by a fiberglass tube.

- The places where the wires come out are covered up masonry mortar.

- Camera dry for 2-4 days.

- Place it against the back wall of the case layer of mineral wool.

- They put it in the case lattice stand on "legs", on it - a muffle.

Important! Lattice plays important role, thanks to it, the heavy muffle will not compress the porous heat insulator.

- The gap between the body and the fireclay chamber is filled with porous thermal insulator (mineral wool).

- To the inner surface of the door attach a layer of porous thermal insulator, fireclay plates.

- The door is hung on hinges, adjust the seals to the dimensions of the chamber.

Photo 2. The finished working chamber of the muffle furnace: metal casing, a layer of insulating material, a brick with a spiral.

The brick does not have to be fixed to the door. When firing, it can be placed directly in the muffle, in front of the door. Next stage installation - connecting the oven to the electrical networkFor this you will need:

- thermostat;

- electromagnetic starter (relay);

- terminal blocks (made of heat-resistant plastic);

- steel casing for the shield;

- electrical twin-core wires;

- fork.

Reference. Technical parameters of the circuit are calculated in advanceBased on the calculations, a thermostat and relay, and heater parameters are selected.

In the electric furnace under consideration, a standard one was selected thermostat M-1-K. The device allows you to set the firing temperature 1250—1350 °C. To switch modes, there is a button on the front panel of the device four buttons. Connection of the thermostat is described step by step in the documentation to the device. The thermostat, electromagnetic starter, and terminal block are attached to the shield box using brackets and bolts.

Possible problems and difficulties

A big problem during construction and commissioning of the furnace is incorrectly chosen electrical equipment, heating elements, coil parameters.

This leads to destruction heating elements or spirals. If the master has no experience in calculating electrical circuits, it is necessary ask for help to a professional electrician.

When laying a muffle from fireclay bricks Mortar or fireclay-sand mixture is not always used. Instead, amateur craftsmen take a regular clay-sand mixture. As a result, already during cold drying in the masonry cracks appear. When the oven is first started, the cracks increase. To solve the problem, The muffle is dismantled and bricks are laid on fireclay mortar.

Advice. For muffle furnace will do fireclay brick with letter "Ш"Bricks with the letter "U" (recycling) are less durable.

In the manufacture of a muffle electric furnace not all home craftsmen install thermostats. This leads to overheating and damage to products already at the first starts. To solve the problem, you should install a thermocouple and a thermostat.

If used for masonry old, used brick, already during test runs, it appears cracksThe camera will have to be dismantled and a new one built.

Useful video

Check out the video, which shows in detail the creation of a muffle furnace: from a drawing with dimensions and explanations to the finished device.

Rules for safe use

The muffle furnace for firing is installed on non-combustible base (ceramic tiles, a layer of brick, a steel sheet under which sheet asbestos or flat slate is laid). If the electrical circuit is designed for 220 Volts, the device must not be connected to a network with voltage 380 Volts and vice versa. Electric ovens are a must grounded.

To work with the oven must not be allowed children should not be nearby when opening the door flammable objects, children, animals.

Loading and unloading of the camera is carried out in closed clothing, cotton gloves and protective glassesLong hair should be tucked under hat, scarf. You cannot open a device that has just been turned off.

To avoid burns You can't take hot items from the chamber, touch the hot parts of the muffle. Place them in a visible place in the workshop a fire extinguisher and a first aid kit.

Comments

If you see heating elements inside the furnace - then this is a regular ceramic kiln! Not a muffle furnace! You need to know the hardware.

Porcelain in such a furnace turns out excellent in my personal opinion. Everything that passes through it turns out almost a masterpiece. I recommend it to you!