Direct the coolant in the right direction! DIY heating manifold: how to make a device

The heating system of a modern private house is a complex structure consisting of several sections that operate separately from each other.

Here different contours can be used: the main heating main with radiators, divided into several floors, heated floors, heating of utility rooms, etc. Therefore, the system cannot do without such a device as a manifold.

It is used to produce distribution of the coolant along the circuits, taking into account the required quantity and required temperature.

Today collectors sold ready-made taking into account the number of circuits and the required diameters of the pipes connected to it. It is also not difficult to make it yourself, in fact, it is just a pipe to which the branch pipes are connected.

Calculation of the heating system circuits of the house and their distribution

Before proceeding to the manufacture of the collector, it is necessary to carry it out accurately calculation taking into account the number of circuits and diameters of pipes connected to it.

- We need to count the contours. Usually a separate section is brought out to each floor. If warm floors are used in some rooms, then one channel is brought out for each room.

- Distance on the collector between return and supply circuits should be 25-30 cm, between the branches 10-15 cm. That is, the device must be made in such a way that it is easy to maintain and easy to control the process of lowering or increasing the temperature in each section.

The main parameter of the collector assembly is hydraulic balance of the structure and the heating system as a whole. It is based on the ratio of the diameter of the pipe used to make the collector and the pipes of the circuits. The sum of the latter should be equal to the diameter of the collector pipe. For example, if a house uses three separate sections in which the feed pipes have a diameter of ½ inch, then the diameter of the pipe in the collector will be equal to 1 ½ inches.

Materials for manufacturing

To make a manifold unit, you can use the following pipes: metal (round and rectangular cross-section) or polypropylene. The connection of the outlet circuits to the collector pipe is made through ball or valve valves, with the help of which the supply of the coolant to each section of the heating system is regulated.

Polypropylene knot

For this purpose, pieces of polypropylene pipe are used, for example, diameter 32 mm (you can use leftovers from the construction of the heating system of the house) and several fittings in the form of tees of the following dimensions 32/32/32 - it is installed at the end of the collector unit, and 32/32/16 — intermediate elements for connection with drainage channels in sections.

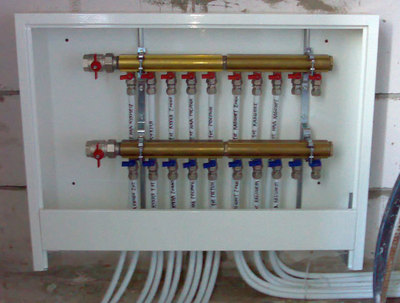

Photo 1. Collector for the heating system, made of polypropylene. The red lines indicate the flow of the coolant.

The first tee is mounted perpendicular to the main pipe. Its two external pipes, located vertically, are connected as follows: An air vent is connected to the upper one, and a drain cock is connected to the lower one. A valve or ball valve is mounted to the opposite end of the manifold installation. A pipe will run from it towards the boiler.

The intermediate tees are connected into one structure, which will be called a manifold. Therefore, the manifold unit is first assembled by welding the tees. 32/32/16 with pieces of pipes 32 mm, after which the tee is installed 32/32/32 and on the opposite side a tap. Then taps or valves are connected to the intermediate fittings on the branch pipes 16 mmIt is with their help that the adjustment of the coolant supply to each circuit will be carried out.

Advantages of a polypropylene device

First of all, it should be noted cheapness design, because for this you will only have to purchase a small number of tees and taps. Other advantages:

- if the welding is done correctly, such a structure will not leak;

- polypropylene is not subject to corrosion, does not rot and does not change its characteristics under the influence of water and high temperatures;

- light weight of the device;

- ease of installation.

From brass fittings

To assemble such a setup use brass fittings and valves.

For this you need the same connect tees with double-sided couplings by means of a threaded connection with the obligatory winding of a sealing material onto the thread.

Moreover, if the thread on the tees is internal (which is most often the case), then the couplings must have external threads and tightening nuts.

The number of tees is the number of circuits, plus one. The latter is installed at the end of the manifold and is connected by two pipes to a drain valve and an air vent.

From a profile pipe

This the most complex process associated with metal welding. This requires skill and experience, because welding two pipes requires complete welding of the joint across the entire thickness of the connected products.

It is recommended to first sketch on paper a precise location of the branch pipes. The branch pipes are taken as elbows with a diameter corresponding to the dimensions of the pipes of the outlet circuits. The parameters on paper are transferred to the profile pipes used as a collector. Their cross-section or 80x80, or 100x100 mm.

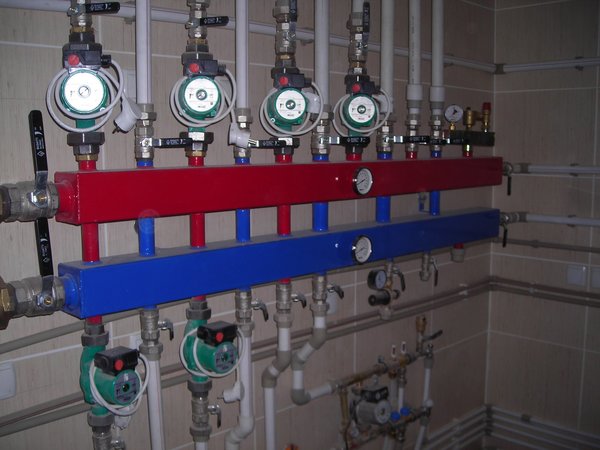

Photo 2. Collector for heating, made of profile pipes. The hot coolant is marked in red, the cold one in blue.

They are marked on one side locations of branch pipes with an exact designation of the outer diameter. After that, holes are cut with a gas cutter or plasma cutter. The couplings are welded to them strictly perpendicularly. At one end, the large pipe is closed with a metal plug (fastened by electric welding).

The same plug is installed on the other side., in which a hole is pre-cut for connection to a valve or tap. That is, a coupling is cut into the hole. Welding areas must be cleaned of scale with a metal brush.

Two such elements are connected into one structure. by installing metal profiles between them. One is connected to the coolant supply circuit, the second to the return circuit. It is better to mark different groups in different colors: toRed is used for feed, blue for return.

How to make a solar collector with your own hands

This device can be used for additional heating of water. It is installed outside on the sunny side so that the sun's rays illuminate the device all the time.

- To make it you need several boards from which the box is knocked together.

- The back wall is closed with any sheet material: plywood, metal, OSB, fiberboard or chipboard.

- It fits inside polystyrene foam panel as insulation.

- Foil is attached over the polystyreneIt will act as a reflector of sun rays, increasing the intensity of their impact on the collector installation.

Attention! As a collector you can use any metal pipe, for example, copper from a refrigerator condenser. It is formed into a coil and laid on top of the foil. The ends of the tube are brought out beyond the wooden box: one is connected to the water supply network, the second is brought into the house as a hot water circuit.

All that remains is cover the entire structure with transparent glass. The device is installed at an angle so that the sun's rays fall perpendicularly onto the collector group.

Rules for connecting fittings

Several options for assembling a manifold for a heating system were considered, but only two of them use fittings.

- Propylene collector assembled by welding plastic, for which a special device is used. The main task is not to overheat the material. Insert the pipe sections into the tees along the axis of the connection. It is prohibited to twist the parts relative to each other.

- As for brass fittings, then The main requirement for assembly is to prevent leaks coolant at the joints. For this purpose, various sealing materials can be used, for example, flax tow, FUM tape or liquid fixative.

Useful video

Watch the video, which demonstrates the process of manufacturing a heating manifold from polypropylene.

Variants of collectors for homemade production

The easiest ways to assemble a manifold for a heating system with your own hands are two: from polypropylene pipes and brass fittings.

But the second one is easier, because, apart from two adjustable wrenches, nothing else is needed here.

As for propylene, for connecting the parts of the device you will need a welding machine.

It is not difficult to work with, but there is a chance that the first few joints will be poorly connected. Therefore, the advice is to make several connections on pieces of waste pipes and damaged fittings.