Maximum savings: making a very efficient and cheap waste oil furnace

Furnaces on waste oil appeared back in Soviet timesBurnt kerosene and other types of oil required safe recycling, and most types of fuel were difficult to obtain.

Thus, recycling turned into re-use - waste oil furnaces allowed to heat a garage, house or cottage efficiently.

Description of the device on waste oil

Waste oil furnaces very convenient in non-residential technical premises, where there is not enough space to store fuel or there is no need to heat constantly.

The devices are used to heat various agricultural buildings where animals are kept, for greenhouses and hothouses.

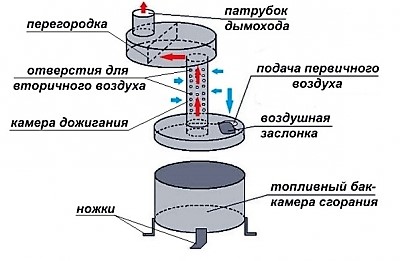

The principle of operation of the furnace is as follows re-burning oils in a special way. The device consists of two combustion chambers connected by a pipe with holes, through which the flow of oxygen is carried out.

Operation is in progress as follows:

- Into the lower chamber waste from the fuel tank is supplied, as well as oxygen through a special blower.

- When oils burn, the hot gases released enter up through the pipe, in which they are additionally enriched with oxygen - this increases the combustion temperature.

- In the upper chamber the process takes place afterburning of combustion products, their final disintegration. The released hot air rises into the chimney and is discharged outside.

To improve efficiency combustion of fuel, the upper chamber is equipped with a blower, providing an intensive flow of oxygen.

Important! Furnace power depends on the volumes of the lower and upper chambers, so they are often made in large sizes.

But the increased amount of fuel in the lower chamber leads to increasing the risk of explosion devices, and a large upper chamber reduces temperature combustion. To ensure reliable operation, drip feed of oil is often installed, and the size of the structures is made small or medium.

The use of waste oil furnaces provides the following advantages:

- functionality — the device is used for heating, heating water, cooking;

- safety - no access to open flame;

- fast, high-quality heating small utility rooms;

- availability - it is easy to make the device yourself;

- easy operation, possibility of transportation.

The designs also have flaws, which are best taken into account in advance:

- noise (hum);

- need for filtration waste oil from impurities;

- hot oven surfaces can become cause of burns;

- the design has to be clean regularly from the carbon deposits settling on the walls.

When installed and operated correctly The device produces almost no soot or carbon, and is also safe to operate.

Fuel

Furnaces on waste oil operate on the following types of technical oils: machine or transmissionAfter use, these products turn into viscous black substance, subject to disposal.

Many companies give away waste at low prices, so even a large purchase of the product will be inexpensive.

Owners of their own car or other equipment also often use the remaining waste oil for heating. It will also work fuel oil and various lubricants. Fuel consumption does not exceed 1-2 l per hour, and the resulting power is equal to the power of the electric heater.

Types of waste oil furnaces

Due to the efficiency of the design, a conventional waste oil furnace is sufficient for high-quality heating. To increase efficiency, they use additional modifications, expanding the functionality or increasing the power of the device.

A regular stove that runs on used fuel

The most common option — a device consisting of two chambers, similar in size (the shape of the tanks does not matter).

Lower chamber must be installed on sturdy stands-legs that are securely welded to the bottom. The tanks are connected to each other perforated metal pipe, which also serves as a support for the upper chamber.

The dimensions of the structure depend on the desired heat output. The device for small rooms will be compact - 70x40x30 cm.

Enough two tanks with a diameter of 30 cm And 10 cm high, length of connecting pipes - 30-40 cm. Chimney, not less than four meters, is attached to the upper tank.

With supercharging

To increase the combustion temperature, a blower is installed. For a standard design with a height of 70-80 cm and width 30-40 cm enough small fan, which is installed on the floor and is connected by an air duct with a diameter up to 10 cm with the upper chamber. It is recommended to install air duct instead of blower on the lower tank. When oxygen is pumped in, the combustion temperature increases - the result will be smokeless combustion of the product, the flame will turn blue.

Drip type

In such a device, the fuel is not contained in the lower tank, but in separate fuel. The remote oil container is located above the level of the lower chamber, is connected to it by a fuel supply pipe. This ensures more stable work, reduces the risk occurrence of a fire hazard situation. If the dimensions of the furnace are 70x40x30 cm, then the dimensions of the tank should not be less than 30x15 cm.

Important! To ensure oil filtration, a filter is installed at the end of the hose immersed in the fuel tank. filter, which is being cleaned at least once a month.

How to do it yourself: drawing

Waste oil furnaces are known for their affordability - it won't be difficult to make the device a person with welding skills. To select a manufacturing scheme, first calculate the dimensions of the room — for a small garage or workshop, a compact unit with a simple circuit will be enough. If the device must perform additional functions, for example, used to heat water, it is better to choose a scheme with a blower. Drip fuel supply will make any type of stove safe and easy to maintain.

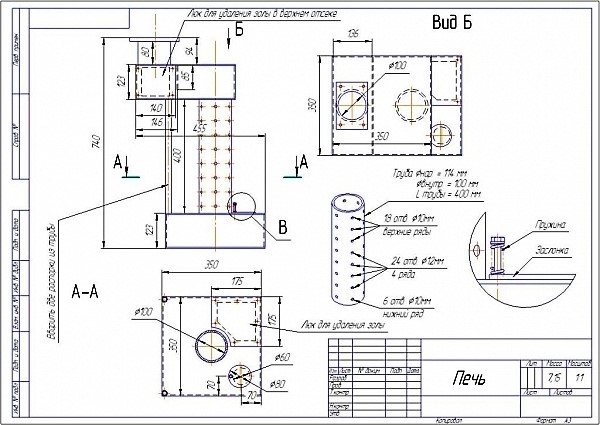

Photo 1. Drawing of a conventional waste oil furnace and its parts. Dimensions are in millimeters.

Materials and tools

To produce a standard design of size 70x40x30 cm will do scrap metal, pipe cuttings, gas cylinders. To make a regular low-power oven, it will do steel thickness 5-6 mm. The tools you will need are: grinder with metal discs and welding machine with appropriate protective equipment (mask and gloves), perforator in order to drill holes in the pipe.

Operating procedure

Before starting production choose a place — a convenient chimney opening is taken into account. Next, the walls, floor and ceiling covered with non-flammable material. In technical rooms where the walls and floor are made of stone and brick, thermal insulation will help direct the heat flow into the room. Manufacturing and installation are carried out in the following order:

- Using a grinder, cut out parts of the lower and upper chambers. It is better to adhere to the standard dimensions - width/length - 30-40 cm, height - 10-15 cm.

- In the blanks holes are cut for the blower, chimney, connecting pipe.

- The lower and upper chambers are welded.

- To the bottom of the lower chamber the legs are welded on (metal corners will do).

- It is being manufactured connecting pipe - a piece of length is cut off 36 cm, they drill holes in it holes with a diameter of 1 cm (six rows of 8 pcs.).

- The pipe is welded to the lower chamber.

- The upper chamber is installed and welded to the connecting pipe.

- A chimney branch is welded to the top of the chamber.

In order to strengthen the structure, the upper and lower chambers additionally joined by a support rod (a non-bending piece of thick steel will do). This will reduce the load on the connecting pipe and eliminate the risk of its deformation when heated.

Possible complications

When making them yourself, it is often allowed mistakes, which affect the efficiency of the device:

- incorrect placement — the surfaces of the device become very hot, there is a possibility of ignition of nearby objects and casing;

- device location in a draft creates a fire hazard;

- oversized upper chamber causes a decrease in temperature, since the oxygen supply is insufficient for intense combustion;

- lack of fuel filtration leads to clogging of the chimney pipe, the presence of impurities causes the risk of fire and explosion.

If you follow all the rules of manufacture and installation, the waste oil furnace will not create potentially dangerous situations.

Useful video

A video that talks about some of the intricacies of manufacturing and operating waste oil furnaces.

How to check a homemade stove before use?

To ensure correct and efficient work It is recommended to check the equipment:

- integrity welding seams;

- lower tank, connecting pipe, chimney for presence blockages;

- cleanliness blower, filter, fuel supply hose;

- lack of moisture (condensate, water remaining after cleaning).

Advice. The used oil must reach no more than half the height lower chamber.

Regular cleaning and inspection the device guarantees safe operation, as well as will extend the service life equipment. Choosing a furnace for waste oil will provide a convenient opportunity to utilize the oil, and will save on the purchase of expensive fuel.

Comments