A great choice for a summer house is a smokehouse made by hand

You are viewing the section At the dacha, located in the large section Smokehouse.

At the dacha, any free space can be used to install a smokehouse. And the best place is where the smoke will not disturb people, plantings, or buildings.

You can do it at the dacha smokehouse of any type: for cold or hot smokedThe first ones differ from the second ones not only in temperature conditions, but also in design.

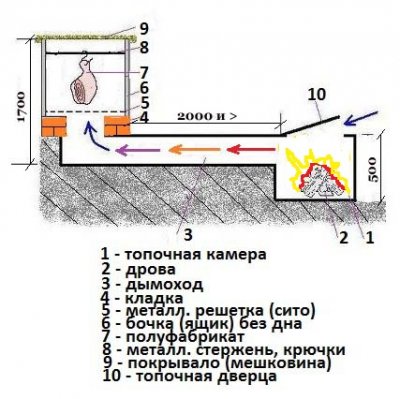

In hot smoking devices the firebox is located under the smoking chamber, and for the cold one - at a distance, not less than 3 meters. This is the main difference between the two types of smokehouses. It also affects the difference in smoke temperature in the devices.

Content

Cold and hot smoking smokehouses for the street, cottage, garden, vegetable garden

At the dacha there is often a need to quickly create equipment for cooking smoked meats. In this case, simple smokehouse from scrap materials. Can be used metal containers of any size: buckets, barrels, tanks, deep basins and pots.

Photo 1. Smokehouse made from an old refrigeratorA similar smoking device can be made from various metal containers.

There are an impressive number of design options for both types of smoking. But they can all be divided into two groups:

A metal smokehouse for hot smoking will help out in cases where fish or meat products have begun to spoil slightly. Such a situation is not uncommon in hot weather. A solid structure that will last for many years, are built from reliable materials: bricks, concrete blocks, foam concrete.

The purpose of building a smokehouse at the dacha is getting tasty and healthy foodThere are no additional functions that would help classify a specific design as a smokehouse for a summer residence.

How to make an outdoor country smokehouse from bricks with your own hands

First of all, a brick smokehouse project is selected. It should include the following elements:

- smoking chamber;

- firebox (also known as a hearth);

- chimney;

- ash pit;

- roof (or lid);

- lattice.

If you plan to build a device of impressive dimensions, it is necessary to arrange foundation.

You can use a ready-made solution or create a project yourself, focusing on the standard requirements for this type of construction.

This could be a solid complex with a barbecue and oven or a simple small-sized brick smokehouse.

Selection of materials

The main building material is brick. It can be used refractory and ceramic, but you can’t give preference to silicate.

Reference. Suitable for the construction of structures and hollow concrete blocks. But in this case, you need to be prepared for the costs of reinforcement and all the components of concrete: sand, cement, gravel or crushed stone. The fact is that hollow blocks will need to be reinforced and filled with concrete.

The metal elements of the smokehouse include:

- tray for collecting dripping fat;

- a grid for laying out products and/or a crossbar with hooks;

- draft control valve;

- door.

Foundation device

The base of the smokehouse should be larger than its dimensions by 10-20 cmThe foundation is built with this calculation in mind. The stages of its construction are as follows.

- They are doing the markings using pegs and a tape measure. Determine the contours of the future foundation.

- Within the markings remove the turf.

- They are digging a hole of the appropriate depth (20-40 cm).

- Level the bottom of the pit And compact it using improvised means or a vibrating plate.

- Sand is poured onto the bottom in an even layer (5-7 cm) and compacted. after wetting it with water.

- On a dry layer of sand they are doing backfilling (on 7-10 cm thickness) of crushed stone or gravel of medium grain size (40x20 mm). Compact the layer.

- The reinforcing mesh is laid.

- Pouring concrete.

Laying the chimney and walls of the smokehouse

The best option would be to choose a masonry from existing schemes and orders. But you can also improvise. In any case, the masonry of the smokehouse begins with the installation of the chimney. For small and medium-sized structures, you will need a chimney at least 35 cm long and 30 cm wide. It can be built made of red brick.

They begin work by laying the first row, which consists of lines of bricks corresponding to the smokehouse diagram, already at this stage it includes walls, firebox and chimney. The mortar is applied to the pre-cleaned surface of the foundation with a trowel, the first brick is placed on it, leveled using pressing and tapping methods. Excess mortar is removed. The process is repeated with the next brick, pushing it tightly against the first one.

Photo 2. The process of laying a brick smokehouse: from the foundation to the walls of the smokehouse.

Optimal scheme of 1 row of brick laying for medium-sized smokehouses:

- Main line from 6-7 bricks, joined together at the ends. Forms the rear wall of the structure.

- From the first and third brick perpendicular to the main line they lay out two bricks each. Connect these lines with two bricks. The outline of the future smoking chamber is obtained.

- Starting from 4 bricks of the main line, they are laid end-on 5-6 bricks next to each other. They receive the base of the future chimney.

- The remaining two bricks the main line is the rear wall of the firebox. It is laid out along the width of the existing grate and door.

Further masonry - building up the contours of the main elements of the smokehouse with bricks and laying all the metal parts at the required height. The ash grate is mounted on the third row of masonry after the installation of the blower. The door is on the fourth.

Installation and design of gratings

Food racks can be made made of thick metal wire or connected to each other stainless steel stripsFor a brick smokehouse that will last for many years, more reliable equipment is needed.

To make such gratings, rods are cut reinforcement bars with a cross-section of 6-8 mm. They are laid in the form of a grid and welded together. Metal corners or plates are welded along the perimeter.

Installing grates during the process of laying the smoking chamber. They choose the most convenient height of the walls, lay the grate on the walls of the smokehouse, apply mortar to the bricks of the previous row and continue laying, building the next row.

Garden smokehouse made of metal

Work on the construction of a metal smokehouse begins with the selection of a project. The main parameters are determined: smoke chamber dimensions. Then they decide whether the design will be intended for hot or cold smoking. For the first option, they design the location of the firebox under the chamber, for the second - through 3-5 meters from it.

Attention! The smokehouse should be installed in a place protected from gusts of wind. There may be buildings nearby. made of non-combustible materials (concrete, brick, metal).

Typical scheme of a prefabricated building smokehouses for hot smoking looks like this: a container (smoking chamber) is installed on a small elevation from the ground, in which there is a tray for fat and grates for products. On top there is a lid with a pipe for smoke removal.

A metal container can be made from stainless steel sheets, connecting them together using welding. But the easiest way is to choose from the available products. These could be:

- buckets;

- gas cylinder without gas;

- washing machine body or refrigerator;

- tank;

- barrel;

- pot;

- medical box.

Stage 1. Making the body

The body of the quickly erected smokehouse is the metal product that is chosen as the smoke chamber.

Step 2. Making the smokehouse lid

You can use wet burlap or a sheet of metal as a smokehouse lid. If you have stainless steel, cut a rectangle out of it and weld a handle to it on top. Drill a hole for a pipe with a cross-section of 10-15 mmA metal tube is welded to it.

Step 3. Making the pallet

You can use foil baking pans or any suitable size products made of heat-resistant material as a tray. The grates are installed on legs that are pre-welded or otherwise attached to them.

Photo 3. A hot smoking smokehouse made from an old metal barrel. A thermometer is built into the walls of the device.

But there is another way to attach the internal equipment of the smokehouse: screwed into its walls bolts or screws. Grids for products are installed on these supports.

Stage 4. A metal rod with hooks for hanging food is attached to the top of the container.

Stage 5. Furnace device.

Two brick walls are built, each of 3-4 bricks. They install the smokehouse body on them. They make a fire between the walls.

In a complex with a gazebo

Those who want to experiment can build a full-fledged stove with a smokehouse, barbecue, oven and unite the entire structure under the roof of the gazebo. The gazebo can be made either closed or open, dividing its area into several zones: for cooking, rest and work.

Most often, gazebos are built made of wood, stone or brickDecorative elements are installed inside, lighting is provided, and the space is filled with furniture.

Useful video

Watch the video, which tells you how to make a smokehouse from a metal barrel with your own hands.

Comments

Since this smokehouse is large and suitable for large celebrations, I made a small one from an ordinary iron barrel to cook for a small company. I think that it is necessary to make an extension to the smokehouse so that there is a canopy and something similar to a gazebo.