Warmth in the house without serious expenses. Types of wood boilers for heating

You are viewing the section Wood burning, located in the large section Boilers.

A wood-fired boiler is a heating unit that is the central element of the building's water heating system.

As the name suggests, the main type of fuel used in the operation of this type of heating boilers is firewood.

At the same time, they often go on sale combination models, allowing the use of both firewood and other energy sources: fuel briquettes, pellets, coal, diesel fuel or electricity.

What to heat the boiler with?

The quality and characteristics of the fuel used is one of the main factors affecting the efficiency of a wood boiler. In this case, it is optimal to use dry logs of medium length from 25 to 35 cm.

The following types of wood are used for heating:

- Oak or acaciaThese types of wood are characterized by low natural humidity, the firewood burns well even without preliminary drying, but it is quite difficult to light it.

- Alder or aspen. The wood of these species is distinguished by the absence of volatile resins and clean combustion. In addition, when firing, the internal surfaces of the chimney are cleaned of soot and tar.

- BirchIn this case, good calorific values are observed: the temperature and duration of combustion are high, but for effective combustion a strong and stable air flow is required. Otherwise, a large amount of tar is released during combustion, settling on the internal surfaces of the smoke exhaust ducts.

Attention! It is highly undesirable to use it as a fuel. softwood due to rapid burnout, as well as increased release of resin and soot, polluting the internal cavities of the boiler.

The volume of fuel required for efficient operation of the boiler, depends on the following factors:

- from the technical characteristics of the model used;

- from the area of heated premises;

- from thermal insulation and natural heat loss indicators;

- from the climatic conditions of the area in which the building is located.

When storing firewood, it is advisable to ensure that the following rules are observed fire safety rules, and also provide the necessary conditions for the firewood did not become damp during storage.

Types of wood boilers for heating

There are many solid fuel wood boilers. In addition to the main technical characteristics (such as dimensions, power, operating temperature range) The differences between the models also include:

- in the material from which the heat exchanger is made;

- in the implemented principle of fuel combustion;

- in the possibility of connecting an additional heating circuit.

Heat exchanger material

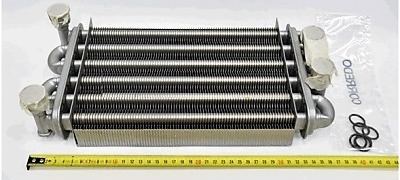

The heat exchanger is an integral part of any wood-fired boiler, since it is responsible for transferring the generated thermal energy to the coolant circulating in the heating circuit. The choice of material largely determines the operational characteristics, as well as the service life of a particular model. The most common boilers are with cast iron and steel heat exchangers.

Boilers with cast iron heat exchangers are durable, the effective service life is at least 20 years. Cast iron is characterized by its resistance to corrosion and high thermal conductivity. However, due to sudden temperature changes, cast iron the structure is easily damaged.

Boilers with steel heat exchangers several cheaper, and the heat exchange and resistance to temperature changes indicators are higher compared to the above-described type of boilers.

However, steel instruments subject to corrosion, due to which their effective service life is from 10 to 15 years.

The principle of fuel combustion

Depending on the principle of fuel combustion, wood boilers are divided into classic and pyrolysis models.

Combustion of fuel in a classic wood-burning boiler is carried out according to the principle of a fire: all the firewood placed in the firebox burns simultaneously. The heat exchanger is located directly above the combustion chamber. In this case, heat energy losses are quite high due to the impossibility of regulating the combustion intensity.

The difference between pyrolysis models is in a different principle of fuel combustion. In their design, such boilers have two chambers. Fuel is loaded only into one of them, while the wood does not burn, but smolders. Due to the lack of oxygen and under the influence of temperatures exceeding 400 °C, smoldering affects only the lower layer of the loaded fuel.

Photo 1. The structure of a pyrolysis wood boiler. In the first chamber, the wood smolders, and in the second, the combustible gas burns.

As a result of smoldering, pyrolysis gas is released, which enters the second chamber through the nozzle. The gas ignites at a temperature exceeding 1000 °C. The intensity of gas flow is regulated automatically in accordance with the set parameters. The efficiency of pyrolysis boilers significantly exceeds the similar indicator of classic wood-burning models.

Reference. In addition to the high efficiency of pyrolysis boilers compared to classic models, they also significantly Increased intervals for refilling fuel.

Number of connected water circuits

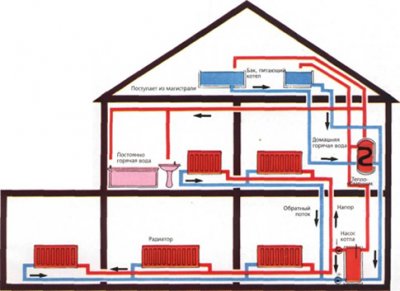

In addition to classic single-circuit boilers, there are also dual-circuit models on sale. The main difference between the two types is in the number of connected water circuits.

As the name suggests, single-circuit boilers allow you to connect only one water circuit, which is directly responsible for heating.

In the design of dual-circuit devices, in addition to the main one, there is also there is an additional heat exchanger, which allows you to connect an additional water circuit to the boiler.

As a rule, an additional circuit is used to provide hot water supply or to operate the system. "warm floor".

Double-circuit boilers are not intended for heating rooms with an area of more than 200 m2. To heat a space whose area exceeds the specified value, you need single-circuit boiler and water heater.

Main characteristics

The main characteristics and attributes of wood boilers, on which depends efficiency and safety of operation:

- Power. The efficiency of heating directly depends on the parameter. The power of the unit is selected in accordance with the area of the heated premises based on the calculation 1 kW generated thermal energy at 10 m2 squares. At the same time, the power reserve is also important, on average amounting to 30% from the resulting value.

- Fuel consumption indicators. This characteristic influences the volume of fuel required for efficient heating.

- External thermal insulation of the boiler. The presence of protection will help avoid burns in case of accidental contact with the external surfaces of the operating unit.

- Supplementing the device with an automatic emergency cooling system, which prevents damage to the internal elements of the boiler when the coolant in the heat exchanger boils or overheats.

Important! Boilers with capacity more than 55 kW It is advisable to install it in a separate room, equipped in accordance with current regulations for the installation of boiler rooms in private homes.

Useful video

Watch the video for some helpful tips on choosing a wood boiler for heating.

The feasibility of using wood-fired heating boilers

Using a wood boiler as the central element of a heating system is advisable if there is no possibility of connecting gas heating, as well as due to the low efficiency of using other energy sources.

Photo 2. Wood-fired heating boiler. The device looks good and can fit into a modern interior.

When choosing a boiler, it is important to take into account the technical characteristics and features of a specific unit, as well as the building that needs to be heated. Optimal choice consists of a comprehensive assessment of existing conditions, as well as the personal preferences and financial capabilities of the buyer.