Recommendations for choosing a suitable stove for a bathhouse made of a pipe with step-by-step instructions

The design of the stove based on an iron pipe resembles a regular potbelly stove. Bath-type units are characterized by the presence of a heater and a tank for heating water.

Before you start building the device, do design drawing.

Without this, starting work is extremely risky, since the likelihood of errors increases many times over, which lead not only to poor-quality work and rapid failure of the unit, but also to health problems for a person while using the device.

Content

Drawings of bath stoves from a pipe

Sauna stove consists of several elements, connected in series to each other by means of electric or gas welding:

- From the body. It has a blower with a lid, a portal for cobblestones, a firebox, and grates.

- From a container (tank) for heating waterSometimes it is made not as a separate element, but as a continuation of the body.

- From the chimney.

- From a spark arrester installed on the chimney.

Water flows through transfer pipes inside the tank and is discharged through cold and hot water supply pipes.

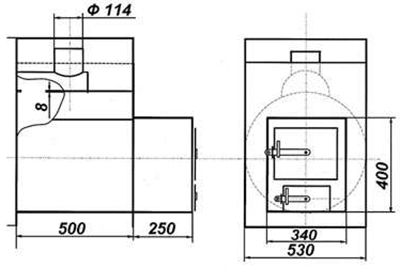

Photo 1. Drawing of a horizontal bath stove made from a pipe, side and front view.

How to make a sauna stove of the right size with a coupling of 400, 500, 530 mm

The choice of a homemade device depends on the dimensions of the steam room and the priorities of the owner. The manufacture of any type of structure is regulated by standards PPB 01–93 and SNiP 41–01-2003. Regardless of whether the oven is horizontal or vertical, a number of general rules apply:

- For the sauna you will need a sheet of 30x35 cm. Distance from the top of the heater to the bottom of the tank — at least ten centimeters.

- The back wall is completely welded, and a door is mounted on the front.

- A coupling made of a steel strip 400, 500 or 530 mm thick is attached on top. Its width is approximately 5 cm. Half is welded to the body, and the protruding part is used for assembly.

- When installing a chimney leave a third of the top of the tank unsealed, so that water can be poured in. A door with a handle is attached to the filling hole.

- A tap with a valve is welded at the bottom of the tank.

Important! The heater is filled with boulders only to half of its space. The inlet can be equipped with an iron rod so that prevent the boulders from falling out.

Vertical homemade device

In a design based on the vertical principle, the grates are located above the heater.

The diameter of the stove will depend on caliber of the selected pipe.

When installing a vertical sauna stove with your own hands, follow the following algorithm:

- Cut off a piece of pipe approximately 0.8 m long.

- The cut edges are cleaned.

- The bottom is welded on from below - a circle of the same diameter as the pipe itself.

- An opening for ventilation is cut out at the bottom.

- The grates are being installed. They are located slightly above the air intake hole.

- A slit for the firebox is cut above the grate.

A hole is made on top of the stove for the chimney. All openings are equipped with doors adjusted to size. After the work is done, the stove is sanded and covered with paint.

Horizontal construction with your own hands: photo

The distinctive feature of this type of device is removal of the firebox from the steam room to the changing room, which makes ignition easier and faster. But horizontal stoves also require much more space.

Photo 2. A horizontal stove with brick cladding, located in the dressing room, requiring a fairly large space for installation.

To make the device, a piece of pipe is taken size 0.8 m, the openings are ground. The grate is installed below. A metal sheet is suitable for it, sufficient to cut out a rectangle of the required size. The middle is cut out of the material, while the edges are not left too narrow. Then metal rods are welded. The finished grate is mounted to the body.

Photo 3. Homemade horizontal sauna stove with a water tank and a compartment for stones.

A metal rectangle slightly larger than the pipe diameter is suitable for the rear section of the device. If you plan to install a heater, this should be taken into account when cutting and add a larger allowance.

It will be about the same size facade sheet. Holes for the firebox and blower are cut in it. Then the form is welded to the front of the pipe. A square hole of about 12x12 cm. This will be the chimney. Next, hang the doors.

Photo 4. A small metal sauna stove with a firebox and blower, with a hole for a chimney.

Before painting, the unit is thoroughly cleaned from plaque and rust. As a finish, the structure can be faced with brick.

Attention! If you paint oven, after the procedure is completed heat up her on the street!

What to be guided by when choosing a project: which design is better to use

When deciding which type of stove to choose, horizontal or vertical, which pipe is better to use, rely on your own preferences, the level of their resources and qualifications.

You will have to take into account the size of the changing room and steam room.

The advantage of horizontal type devices is that due to the low position of the body and the long firebox the heating area of the cobblestones is larger.

This increases the natural convection of hot air in the steam room.

If the room dimensions allow, it is better to choose a horizontal unit.

Necessary materials

To make a sauna stove you will need:

- A pipe made of any metal with a diameter of 50 cm and a length of up to one and a half meters. It is important that the walls are whole, without holes or patches. If there is a hole, you can make a firebox in this place.

- Coupling.

- Metal sheets with a side not less than the diameter of the pipe.

- Container with valve.

You will need tools: a welding machine, a hacksaw for metal.

We install the foundation for the stove

Any stove, no matter what it is made of, requires reliable and strong brick foundationFor a light metal stove, a foundation height of approximately in 70 cm.

First, a pit is prepared, the top layer of soil is removed, and the ground is leveled. Sand is poured onto the cleared surface and compacted.

Next, the reinforcing mesh is stretched and the plane is filled with concrete. We lay red solid bricks flat on the concrete surface.

Preparation of a pipe with a blower of 200 and 250 mm

Before installation, the pipe is cut into two parts measuring 60 cm and 90 cm. The first piece will go under the water tank, the second - under the firebox and the heater. Next, the blower is cut out - a rectangle measuring 200x60 or 250x60 mm. A round steel plate about one and a half centimeters thick is welded on top.

Difficulties in manufacturing

Only a person with basic knowledge of stove making and also having the ability to make such a unit on his own can do it. skills in working with a welding machine. Only under this condition can we say that building a sauna stove from a gas pipe is a simple undertaking.

Reference! In all other cases hire a team to do the work. Gaps in knowledge and a makeshift approach lead to serious consequences.

So, during the welding process, two most common problems arise:

- Too much draft in the future stove. In this case, it is necessary to install a valve in the pipe in advance.

- Risk of soot fire. Neglecting this nuance is fraught with an invariable deterioration in the quality of heating and explosion hazard. This can be avoided in a horizontal furnace by using an afterburner.

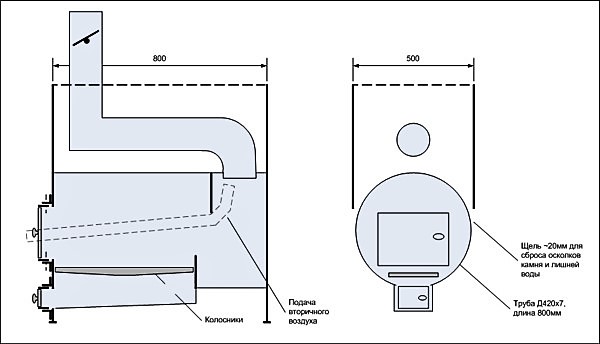

The afterburner is made like this: a horizontal platform is welded to the top of the body, covering half of the entire space. Even higher, almost at the very top, two holes are made in the wall of the stove. Small cylinders are welded to them (the gaps are in the form of tubes), which are then slightly bent towards the pipe.

Useful video

The video shows the stages of making a durable metal sauna stove from an old pipe.

What are the advantages?

Stove from a pipe for a bathhouse more durable a regular rectangular or faceted design, retains heat better, And it's several times easier to install. Thanks to the sealed housing it is possible don't worry about the bathhouse attendant's safety. The heating unit for a bathhouse made of metal also differs with ease.

Before constructing the device, you will not have to look for materials to build the structure. The parts for the unit are sold at any construction market and differ at a reasonable price.

Comments

The pipe itself is 1000 mm in diameter, about 10 mm thick, I didn't measure it exactly, I lined the firebox with bricks inside, I also lined the stove inside with bricks but with cells, the stove is closed and the stones there are heated by an open flame, everything warms up well and quickly. True, in order to drag such a pipe, I even had to remove the jambs in the bathhouse, then install them in place, but this work was then justified, the heat in the bathhouse lasts for a long time. If the frosts are not severe, I don't even drain the water there.