Let your stove "breathe" easily: installing a chimney from a pipe for a sauna

The bathhouse has long since become a unique institution in Russian culture. national element.

And if earlier our ancestors had to wait until the last embers burned out and only then begin to take water procedures, then with the advent of the chimney the situation changed dramatically.

Its device is responsible for removing carbon monoxide to the outside, minimizing possible risks "to get burned out", and allows you to keep the premises clean, preventing soot from settling on its walls.

Content

The design of the chimney for sauna stoves: which design is better?

In the entire design of the bathhouse, the chimney plays an important role - removal of combustion products.

In addition, by skillfully manipulating the air flows through the chimney pipe, you can regulate fuel consumption and the ability of the furnace to give off heat.

Thanks to the chimney, you can maintain the fire even during the steaming process in the bathhouse.

Device chimney pipe often varies depending on the type and materials manufacturing. Depending depending on the installation method, chimneys are divided into:

- internal, which provides additional heating for the room, but creates an increased fire safety risk;

- external, which do not pose a fire hazard, but will require additional fuel for heating.

From a technological point of view, the internal location of the flue is more complex, but it allows you to save a valuable resource - heat. In conditions of high energy costs, this factor has a significant impact on the choice of the type of flue design.

Important! When choosing installation external chimney, smoke exhaust additional insulation using mineral wool, and the pipes are installed outside, along the facade of the building.

The design of chimney pipes also varies depending on the materials they are made from. There are quite a few of them, but two designs stand out in principle: brick and the chimney from a metal pipe.

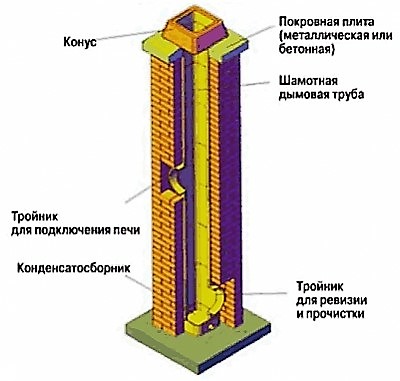

Brick construction diagram

The main advantage of a brick chimney is heat resistance and thermal conductivity.

However, it is worth noting that the construction of this type of chimney is a very complex matter. laborious and painstakingSuch chimneys are usually used for metal and stone stoves.

Main material During construction, fireproof bricks are used, and a solution based on clay or special “furnace” mixtures is also used.

During the construction of a chimney, it is necessary to maintaining perfect evenness of the masonry both the structure as a whole and its individual functional elements.

In order to smooth out the surfaces and reduce the amount of soot and condensate that accumulates in the chimney, the pipe is plastered from the inside, smoothing out seams and unevenness. In addition, this will have a positive effect on traction.

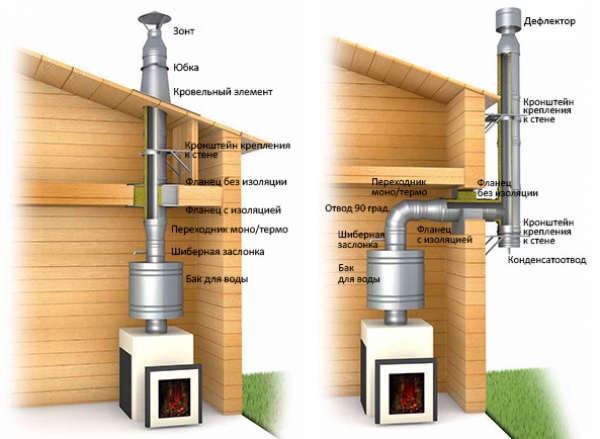

Metal chimney diagram

Metal chimneys easy to install and will cost an order of magnitude cheaperHowever, unlike brick construction, metal has a very high heat transfer. Fires are not uncommon as a result of the burning of the metal chimney pipe.

Steel pipe chimneys are installed directly on top of the stove. Most often, it is required section 115 mm, but this figure may vary depending on the power of the heat source or specific recommendations of the manufacturer.

Photo 1. Diagrams of two options for installing a metal chimney: inside the house and outside.

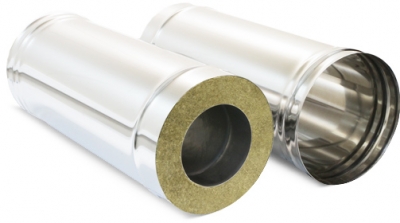

As experience shows, the best material for making this type of flue gas duct are pipes made of stainless steel. Its structure can be single, provided that it is well insulated. However, there is a more practical solution - sandwich pipeSuch a channel essentially consists of two pipes of different diameters, and the space between them is filled with thermal insulation materials, in particular mineral wool.

Exists a number of features and requirements, which extend to steel flues:

- internal wall thickness should be from 0.8 mm;

- steel must be resistant to temperatures up to 850°С inclusive;

- indicator thickness of basalt filling must begin from 50 mm, and his density — from 120 mg/m3;

- model external It is better to choose pipes in the same way made of stainless steel.

Installation of a chimney for a bathhouse from a sandwich pipe

The flue gas exhaust system made of steel pipes is the best option in terms of price-quality ratio, and requires the least labor costs.

Preliminary preparation: diameter measurements, selection of tools

Before you undertake the independent installation of a chimney, you need to take the time to thoroughly design of this enterprise:

- Measure distance between the roof ridge and the pipe ovens, then add another 50 cm and get the total height of the chimney.

- Divide the pipe into upper and lower parts, which will later be secured with a clamp at the middle height of the attic. The upper part insulate.

- Calculate the size of the protective cover according to the formula d * 3.14 + 30 mm, Where d — pipe diameter including insulation.

- Do it two galvanized blanks for both parts. Their size should be slightly larger than the holes in the ceilings.

- Prepare a metal strip for the clamp 20 cm wide, and its length is calculated by formula P + 30 mm, Where P — the circumference of the outer pipe.

- Cut out 4 galvanized rings, which will be used to secure the insulation in the future.

- Weld a strip to the bottom edge of the top pipe 4 cm wide, into which the upper end of the lower part of the pipe will be inserted.

In addition, in your work you The following tools will come in handy:

- Bulgarian;

- set of locksmith tools;

- galvanized sheet with thickness 0.8 mm;

- steel sheet with thickness 2 mm;

- metal shears;

- stainless steel metal pipe;

- mineral wool.

The order and rules for doing the work yourself. Where to install the damper?

Having carefully prepared, you can begin to assemble and install the flue. To do this, you should cut out in the ceiling and roof holes measuring 450*450mm.

You need to cut it out according to the same dimensions two metal blanks. A round hole is made in one of them, and an oval one in the other (it is attached to the roof slope).

The insulation is put on the pipe and secured with a galvanized casing, and the ends are covered with metal rings with edges concave inwards. Then it is placed on the branch pipe furnace, and its upper part is placed in the passage on the ceiling. After which the opening is closed with a galvanized blank.

A pipe with a welded metal strip is placed into a passage located on the roof. Lower and upper part they are placed on top of each other and tightly are fastened with a clampFrom the inside of the roof, the hole is covered with a metal plate. Very important fill the free space between the flue and the ceilings with something non-flammable substance: asbestos, expanded clay, clay.

It is worth mentioning such a device in the chimney as a damper. It allows regulate air flow and most often has the form of a metal valve.

Important! Gate necessary in home stoves to keep the heat longer. In bathhouses, its presence is not required., and is considered a relic of the past.

As a final stage of installation, it is necessary to thoroughly heat the stove with wood. This way you will check the functionality of the smoke exhaust: if there is no foreign smell of smoke and no sparks fly anywhere, then the installation can be considered successful.

Useful video

A video that reveals some of the intricacies of installing a chimney: the main types of outlets, which of them will be easier to clean later.

Recommendations for the care of the chimney of a wood stove

The chimney needs regular cleaning. The most proven and simple way is mechanicalTo do this, you need to arm yourself with cleaning products. with ruffs and weights. In rare cases, they will come into play crowbar and sledgehammer.

A good preventative measure to clean the flue from ash and soot would be to fire up the stove from time to time. aspen firewoodIn this case, excellent draft is created, which sweeps out all unnecessary things from the pipe.

In particularly severe cases, or if there is no desire to fiddle with a brush, there are special chemicals cleaning.

The principle of these devices is that they collect not only soot, but most importantly condensate, which inevitably forms in the chimney at the beginning and end of the firebox. The system is very easy to clean and allows you to save fuel. As is known, with a straight-through pipe, most of the heat "flies into the pipe."