Bake in 5 Minutes: Italian Wood Fired Pizza Oven

A wood fired pizza oven is domed semi-open hearth.

The device must maintain temperatures well. over 400 °C, have a stone hearth and ensure free air circulation from the bottom up inside the chamber for even and fast baking.

Types of Wood Fired Pizza Ovens

Pompeian constructions are divided into two types - Neapolitan and Tuscan.

Neapolitan - is different low dome and is intended exclusively for making pizza.

U Tuscan furnace vault options tall and round. Which allows you to bake not only pizza, but also bread, or cook various dishes on the grill.

Technical specifications

Common to both types of furnaces are: entrance arch proportions relative to the furnace dome. The width of the ceiling is equal to the level of the vault along the inner radius, and the height is equal to 60-80% of the height domes of the furnace. At the same time optimal lower diameter the inner chamber is about 1 m. Too wide structures accumulate thermal energy inefficiently, while small ones are inconvenient to operate and have low productivity.

The distinctive feature of the Pompeian oven is smoke exhaust, located in front and above the entrance to the arch. It is this device that allows oxygen and combustible gases to actively circulate from the bottom up and ensure uniform and rapid baking of products.

The height of the chimney depends on its locationIf the wood stove is installed under a canopy, the chimney must extend beyond the roof to avoid smoke.

When installing the structure in the open space the height of the chimney may vary within 0.5-1 m.

For heating straw or hardwood firewood is used virtually smokeless when burning:

- Alder.

- Oak.

- Beech.

- Ash.

Important! Not allowed to use pellets, wet and coniferous firewood that produces a lot of soot when burning. This will negatively affect the taste of the finished dishes and the general condition of the unit.

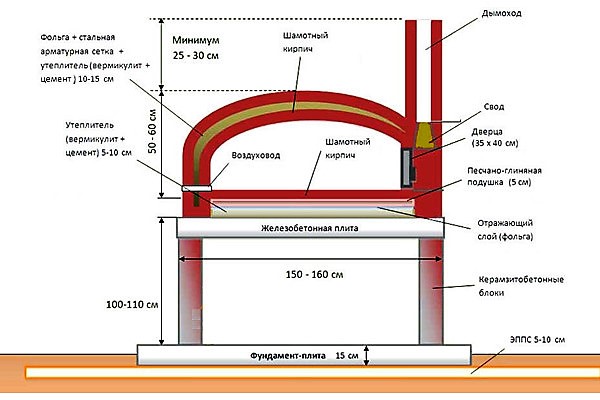

Construction diagram

- Foundation.

- Pedestal.

- Table top.

- Entrance arch.

- Under.

- Dome.

- Smoke exhaust.

Photo 1. Detailed diagram of the Pompeian pizza oven with explanations and dimensions.

When laying the foundation, it should be taken into account that the stove will have weight not less than 700 kgThe foundation must be strong and level to ensure the durability of the entire structure.

Stove pedestal is a continuation of the foundation and lifts the structure itself to a height of about 1m.

Table top is a working area. It is placed on a pedestal and the bottom of the furnace chamber is formed on it. The bottom should be perfectly smooth, since the pizza is baked directly on it without any devices.

Important! The hearth material must be safe by its composition for cooking.

An entrance arch is formed around the bottom and stove dome observing the proportions of a specific scheme. At the top of the ceiling, a rectangular opening is left for connecting the flue.

Materials for building Italian stoves

The construction chamber is manufactured made of fireclay bricks. And you can also take firestone. Fireclay is used for the solution. sand and clay, cement mixtures are not suitable.

Attention! To form the dome and the bottom the use of ordinary bricks is not allowedOtherwise, the chamber will crack and the masonry will begin to collapse.

Foundation It is a reinforced concrete slab laid on a bed of sand and crushed stone.

For the construction of the pedestal The foundation can be made of ordinary clay bricks or silicate blocks. As a rule, the pedestal has a niche for storing firewood or dishes.

Table top It can also be made of brick and stone, but it is better if it is monolithic. For this purpose, a ready-made slab is used or the solution with reinforcement from reinforcement is poured into the formwork independently. Recommended thickness countertops - 100 mm.

A space is required between the oven floor and its countertop. layer of hydro- and thermal insulation to avoid heat loss and destruction. Separation is carried out using Calcium silicate gaskets, expanded clay or perlite sand filler.

The outer part The oven also requires insulation, which consists of several layers:

- Heat-resistant plaster over the brickwork.

- Basalt mineral wool.

- Decorative moisture resistant finishing with a special mixture, stone, tiles.

Smoke exhaust pizza ovens perform made of brick, metal, asbestos in the form of a pipe or box.

When constructing a furnace vault, they use articulated and radial spherical templates, made of plywood, lumber and metal parts. Without stencils, the dome will not be semicircular.

Important! If the stove is planned to be installed outdoors, it is necessary canopy, protecting the structure from atmospheric precipitation.

Useful video

A video that shows in detail how and from what materials it is convenient to build the vault of a Pompeian oven.

Advantages and disadvantages of Italian wood stoves

TO cons can be attributed to:

- Labor intensity of construction.

- High cost of materials.

- Long commissioning cycle.

Advantages wood stoves are:

- Warming up up to temperatures of 300–450 °C per hour and high heat output, which allows you to bake pizza within 2-5 minutes.

- Only in a wood-fired Italian oven can you make pizza according to the classic recipe. The product turns out soft, with a crispy crust and a light smoky aroma.

- The compact size and unusual shape of the stove will decorate any design solution.

Comments