How to achieve unusually high productivity? Do-it-yourself Buleryan stove: diagram, drawing

To heat temporary barracks for workers in logging areas, Canadian engineers have come up with an original stove.

Buleryan uses the principle of pyrolysis decomposition of wood And combustion of gases in the secondary chamber. The stove turned out to be so successful that the operating principle of this stove is copied by different manufacturers; it is installed in warehouses, greenhouses, garages and even in expensive mansions.

Furnace specifications

The Buleryan stove is responsible for heating and maintaining the temperature in the building. It must have the following parameters:

- Power. The Buleryan can be made either small or very large, and adapted for operation in buildings with an air volume up to 1500 m3.

- EaseThe stove does not take up much space during storage or transportation and does not require high chimneys.

- Technological and easy to manufacture. The oven can be made by any competent welder in the garage.

- High efficiency. This is achieved thanks to a large heat exchange surface and complete combustion of fuel.

- Long burning. If used correctly, it is enough one or two bookmarks firewood per day.

- Omnivorous. You can burn dry wood in any form.

- Original appearance. With the proper technological level of manufacture, the stove can decorate the interior of a country house in an industrial style.

Design Features

Buleryan stoves They differ only in size and additional elements.

- The firebox is formed from bent pipes round or rectangular cross-section, which serve as a convection jacket and body. The design resembles a horizontally installed cylinder welded from bent elbow pipes.

- The door can be round or squareIts size is more important - the larger it is, the easier it is to maintain and load more firewood.

- In Buleryan there is no ash pan or grate. The air supply is regulated by a valve on the door, which can be used to completely block the oxygen supply.

- Secondary chamber - afterburner chamber - separated from the firebox by a screen made of bent thick sheet steel. It starts on the second or third knee of the firebox.

- An important feature of the oven is presence of air injectors. These nozzles supply air into the combustion chamber of pyrolysis gases from the first knee of the body and increase the efficiency of the stove. up to 85-90%.

- For proper operation additional fittings are needed — locking mechanisms, door seals, air supply and release valves.

- Increased heat removal and operational safety are ensured by sheet steel heat shieldsThey also give a presentable appearance.

There are stoves on sale that are similar in appearance to the Buleryan, but have important differences. Such stoves do not have an air jet (secondary combustion chamber). Some craftsmen insert grate bars and ash chamber into the firebox. These elements are not inherent in Buleryan.

How to make a Buleryan sauna stove with your own hands, diagram and drawing

The design of the Breneran (Buleryan) stove is quite simple, materials and technologies are not complicated. That's why this stove has earned real love. It is capable of both maintaining heat and quickly heating up a large volume of air.

Photo 1. Scheme of the structure of the Buleryan wood-burning stove. Arrows indicate parts of the stove structure.

Buleryan stove of our own making perfect for heating greenhouses, utility rooms, garages, workshops, baths. The larger the room, the larger the firebox should be.

When building, prepare only new metal. Walls thinned by corrosion will quickly burn out and the stove will not last long. For optimal operation, the metal thickness should be within 3-5 mm. It will be required 12 pieces of 2-inch pipe, 1.2-1.5 meters each, sheet iron for the shelf, ends and door, a piece of pipe with a diameter of 120-150 mm for the removal of hot gases, rods of different diameters for dampers and shut-off elements.

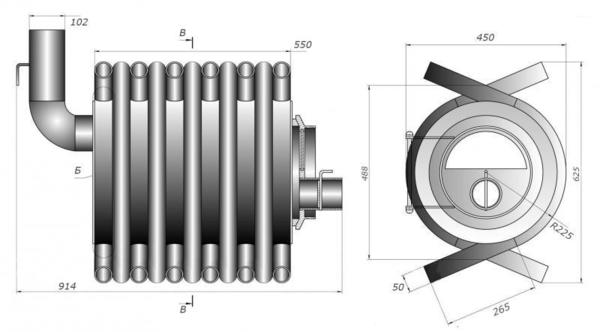

Photo 2. Drawing of the Buleryan wood-burning metal stove with dimensions. Front and side views.

You shouldn't use galvanized or painted pipes. — the quality of the welds is worse, and during operation of the furnace the coating will burn off.

Attention! Zinc and paint combustion products have a bad effect on health!

What skills will be needed?

Welder 4th category will provide beautiful sealed seams, but If you don't have welding skills, it's better not to try. Metalworking skills are required to a lesser extent - even if it is crooked and ugly, the stove will heat properly.

It will also come in handy skill in using an angle grinder — there are a lot of cuts in the stove.

Important! Protect your eyes and skin when working! Watch where sparks fly. Do not remove the protection from the grinder, Use appropriate discs.

You will need the following tools:

- Pipe bender for round or square pipes. If you don’t have one, you can use a homemade device in the form of a lever.

- Cutting tool — plasma cutter or angle grinder (grinder).

- Measuring - tape measure, caliper, end needle templates.

- Hand tools - vices, hammers, files, wire brushes.

Work order

The construction of a Buleryan consists of simple logical stages and production will not take much time and effort.

- We bend pipes. We use a pipe bender or a lever, if necessary, fill the pipes with sand and heat them. A smooth bend of 90 degrees will be optimal.

- We assemble the first 5 sections. We place the pipe on a flat surface, and place the second one on it, forming the walls of the firebox. Short sections of pipe of the same diameter can serve as linings.

- We make a shelf for the secondary chamber. First, we make a template out of thick cardboard, and then we cut and bend the metal sheet according to it. We weld it.

- We manufacture air injectors. The air flow is directed to the lower part of the secondary chamber, and the injector tubes are well heated by the furnace flame. The injectors have the form of a curved tube, inserted with one side into the first convector tube.

- We connect the remaining air ducts and weld them. We fill the gaps with a strip of metal. The result is a sealed cylinder.

- We manufacture and weld the ends of the stove. We weld an outlet for hot gases from the secondary chamber to the rear one. The front end has a cutout for the door.

- To this cutout, perpendicular to the end, we weld a flange made of a flat strip of metal. The door seal is pressed against it to prevent unauthorized air from entering.

- We make a door wider than the outline of the bank. It is a sheet of metal with curtains and locking fittings; two edges are welded on the abutment side, between which a sealing cord is laid.

- We install the blower. This is a piece of pipe welded perpendicular to the stove doors. We install a rotary damper inside the ash pit. Make sure that the damper is not completely tight - even when closed, combustion should not stop completely. If there is a need to extinguish the fire, a plug is put on the ash pit pipe.

The stove is ready! Its surface can be coated with bluing or heat-resistant paint. If desired, we manufacture heat-insulating screens that follow the contours of the furnace.

Pitfalls

The Buleryan has a simple design, but even an experienced craftsman may encounter difficulties. Do not rush when adjusting the parts - It is better to use cardboard templates and needle end templates for round pipes.

Photo 3. The finished Buleryan stove installed indoors. Protective screens are installed around the stove.

Buleryan needs good warm chimney. If you only have a brick stove, be sure to insert a stainless steel sleeve there. The Buleryan is a "greedy" stove, the temperature of the outgoing gases is low. The steam contained in the smoke condenses and flows down as condensate, so heat the stove with dry firewood and insulate the chimney.

Don't make the Buleryan too short - the firebox should be minimum 35-40 cm long.

All welds must be hermetically sealed. After installing the back cover, turn the stove on its end and fill it with water. Wet seams will indicate where to finish welding or rework the stove.

Useful video

Watch the video, which demonstrates the production of the Buleryan stove in the form of a slide show.

How to stoke a Buleryan correctly

Read the instructions before heating! The operating mode of this stove differs from others. Violation of the rules will lead to burnout of the walls, failure of the stove.

The Buleryan is first filled with kindling chips. Firewood is placed on top - the firebox should be packed tightly. It is better to use logs split in two 10-15 cm shorter than the firebox. Firewood should be dry, preference should be given to birch, oak, acacia and other hardwoods wood.

The chips are ignited and the door is closed tightly. The air supply is open. 10-15 minutes, until heat is generated and the secondary chamber is warmed up.

Then the air supply is reduced to a minimum and in the firebox two processes occur: decomposition of firewood into pyrolysis gases and ash and combustion of these gases in a secondary chamber using air from injectors.

Correctly configured Buleryan does not emit smoke - everything burns cleanSimplified analogues are heated in a hot mode, like a simple potbelly stove; such stoves have no right to be called Buleryan.

Error the owners of the stove - Frequent removal of ash. The Buleryan stove cannot be completely cleaned; there should always be ash on the bottom, which protects the bottom of the firebox from overheating and helps maintain the smoldering mode.

The Buleryan stove only runs on dry hardwood. They provide the highest efficiency during pyrolysis combustion.

Comments