3 Ways to Make a Garage Stove with Your Own Hands: Cheap and Effective

In winter, it is problematic to carry out work and repairs in a garage without heating, and if electricity is supplied to all garage areas, then heating is very rare. Therefore, there is only one way out - to use a stove.

Garage stove should be compact, simple in manufacturing, quickly heat the air and operate on a wide variety of low-grade fuelsThe simpler the design, the better, the main thing is to be able to make it yourself.

Types of Garage Furnaces

You can find gas and electric appliances on sale, they are effective, but expensive, require regular refueling and careful handling. The most popular options use the energy of burning wood, diesel fuel or waste oil.

From a gas cylinder or pipe

The option is attractive ease of manufacture. Located vertically, these stoves are very compact. A gas cylinder can be found at a dump or metal collection point, after which it is easily converted into a stove.

The design of the furnace can be vertical and horizontal. The first option is more compact, in the second case it is more convenient to stack long firewood. Wall thickness – not less than 3 mm, the best thing is – 5-6 mm.

The chimney should not be too thin either. Such a stove will serve for a very long time, and it can be fired with wood waste, chipboard, sawdust, pellets, coal.

Can be used two-barrel system, located one inside the other, the space between them is filled with pebbles or sand. The structure takes longer to heat up, but it radiates even heat and does not cool down for a long time. In general, there is no standard for making a conventional wood-burning stove.

The main thing is that it is necessary follow simple rules: use a thick steel wall, firebox and ash pit, grates to improve combustion and an exhaust pipe with a diameter not less than 10 centimeters.

Advantages of wood stoves:

- ease of use;

- low cost of the device itself and fuel for him;

- installed without foundation to any suitable place;

- high efficiency and very fast warm-up garage;

- can be used for cooking.

Long burning wood burning design

To avoid having to add more wood to the firebox frequently, stoves were invented. with limited air access to the combustion zone, such devices can work up to 12 hours on one fillThe same gas cylinder is used as a body.

Photo 1. A homemade wood-burning stove in the garage, which is convenient for heating dishes, such as a kettle.

Combustion occurs from top to bottom under the action of the load, resulting in the combustion of the wood itself and the pyrolysis gases formed during heating. Efficiency such a stove high, and the wood in it burns almost without leaving any residue.

Oil-fired and diesel stoves

The idea of using old motor oil has led to the development of a device capable of burning it releasing a large amount of heat.

The lower container of the device serves as a fuel reservoir, and the main combustion process occurs in the upper half, so its walls must be thicker. The heating temperature can reach 850–900 °C.

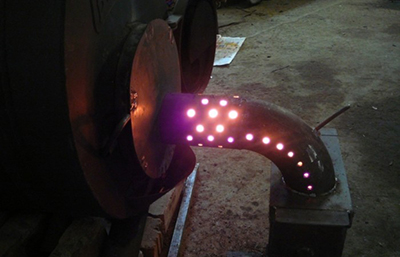

Photo 2. Oil furnace in the garage. The device is small in size, with good heat transfer properties and no soot.

Advantages of using waste:

- fuel availability;

- absence in the combustion process smoke and soot;

- safety and environmental friendliness, only oil vapors burn;

- compactness;

- good heat dissipation.

Important! The chimney must be high up to 4 meters to ensure good traction and stable operation.

The design of the diesel fuel furnace is similar to the unit that operates on waste oil.

To increase efficiency, simple nozzles can be used in the lower part of the burner.

Such furnaces are used:

- diesel or heating oil;

- fuel oil;

- kerosene;

- transformer, machine oil.

Making the device yourself

When choosing the type of stove to use for heating the garage, you should decide on fuel for the device. If waste oil is hard to come by, then there is no point in a liquid fuel device. Solid fuel furnaces are more versatile, and with minor modifications they can run on oil and fuel oil.

Reference! The simplest such device is made from unnecessary materials propane tank, pipe cuttings, various scrap metal.

Necessary tools

- Bulgarian;

- drill and drill bits for metal;

- welding machine or inverter;

- locksmith tools, hammer, ruler.

Work process

Before starting work, be sure to drain the remaining gas from the cylinder. To do this, unscrew the valve or cut it with a hacksaw for metal, pour water through the neck of the cylinder until the smell of gas disappears. After this, drain the water and calmly cut the body with a grinder.

Attention! You can't cut the cylinder without preliminary degassing, this may cause an explosion of the vapors remaining there.

- A horizontal stove design would be more convenient. A hole is drilled in the location of the ash pan 3-4 rows of holes with a diameter of 8-12 mm along its entire length. In one of the ends, a firebox opening is cut with a grinder. This piece will later serve as a door.

- Marking out the place for the pipe, drill around the perimeter and trim with a grinder. You can burn this hole with an electrode if you have experience with such work.

- From a piece of suitable sheet bend the ash pan body and weld it. Hinges are welded to the door and it is hung in place.

- The door can be a standard cast iron one., but for this you will have to make an adapter from corners and weld it to the end of the cylinder. Instead of a door, you can make an adapter with a burner for working on liquid fuel. In this case, the garage stove will be universal.

- From corner trimmings make the legs and weld them to the body.

- The stove is installed in place and the chimney is led out over the roof., its deviation from the vertical should not be more than 30 degrees.

- A heat-reflecting screen is installed along the walls from a sheet of tin or foil, the stove itself can be lined with bricks for better heat retention.

What difficulties might arise?

The most common problem encountered is welding thick sheets of metal and individual parts of the structure. For a smooth weld, it is necessary use electrodes of appropriate thickness.

Another difficulty that arises during construction is poor traction or smoke filling the garage during the heating process.

The solution will be chimney outlet above roof level and installation of a deflector at its end. With its help, a vacuum will be created in the pipe. The quality of combustion is affected by the holes in the ash pit and the distance from the grate to the bottom of the stove.

If you thought that the oven does not heat well room, and the firewood just “flies” into the chimney, then you can do it several turns on the chimney pipe. The speed of the flue gases will drop, and most of their energy will remain in the garage. It is useful to weld the steel structure of the stove with additional heat exchanger fins, and even better to make a water jacket and a liquid circulation system through pipes.

Useful video

The video tells about a garage heater that runs on diesel fuel antifreeze.

Safety precautions when using a homemade stove

- Firewood and flammable materials are stored at a great distance from the operating oven.

- For liquid devices, only heavy fuel is used. Acetone, gasoline, solvent, and alcohol are used for ignition.

- Always have a fire extinguisher or sandbag on hand.

- Do not close the outlet valve, while the remains of firewood are smoldering in the firebox. There is a high probability of carbon monoxide poisoning.

- Do not overheat the wood stove. The red-hot walls can damage the car's paintwork.

Any version of a stove made by yourself will allow you to make repairs in winter and maintain a favorable microclimate for the car. This useful device should be in the garage of every self-respecting car owner.

Comments