Much more efficient than wood burning devices! Coal stove for home and bathhouse

Often, a coal stove is chosen for installation in a country house or bathhouse. heat output is one and a half to two times higher than that of wood burning stoves due to the fact that coal burns at a higher temperature.

This type of stove is characterized by a simple design, reliability in operation, and also economy due to the low cost of fuel.

Operating principle and design

I use coal stoves to make them.t brick or metal (cast iron and steel)Metal devices are more compact, but they become very hot during operation and require the installation of a protective screen.

Brick has the ability to accumulate and gradually release heat, so these stoves allow better use of the high heat output of coal fuel.

For efficient operation of equipment good traction is important. When coal burns, air enters the firebox from below, not from above, as when burning wood. Therefore, instead of a bottom, a grate is installed in the furnace chamber. The ash pan located under it functions as a blower when the door is open.

Temperature in the furnace firebox can exceed 1100 degrees.

In order to ensure the durability of the masonry, they use heat-resistant fireclay brickIn some cases, the chamber is additionally reinforced with thick sheets of refractory steel or a cast iron firebox is made.

Attention! There is often a temptation to exploit the high efficiency of a coal stove by building a heating shield or a multi-channel chimney. But this will result in a deterioration in draft, which will create a risk of carbon monoxide poisoning.

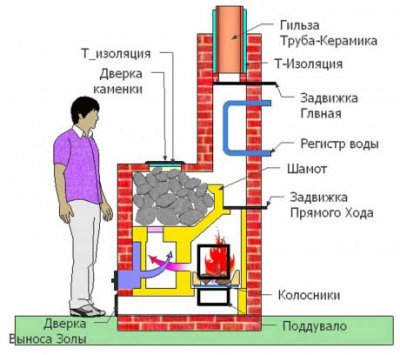

Coal stove diagram for home

The design of a brick coal stove is almost no different from the design of a regular wood stove.

It consists of, arranged in a certain sequence: foundation, ash pan, firebox, vault, chimney.

The main difference of a coal stove is reinforced firebox and increased ash pan volume (burning coal produces more ash than burning wood).

Also, a larger grate must be installed (ideally, it replaces the bottom of the firebox).

The coal in the furnace firebox burns from below, so the walls of the compartment are made inclined - this design helps the upper layers of coal to descend as they burn. The dimensions of the standard device are 110x900cm, height without chimney - about a meter.

For the bath

The bathhouse device is characterized by the presence of a heater - a container for stones. Together with it, the height of the stove will be 1.6m, length 1.1m, width 90 cm. The heater is made open and is located in the upper part of the stove. Because of this, the chimney is located not above the firebox, but on the side.

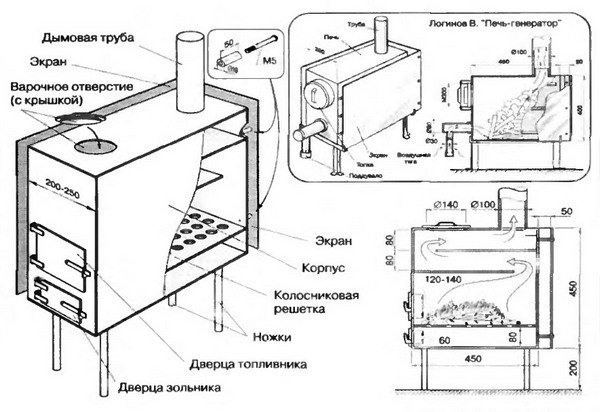

More compact metal stoves are often installed in the bathhouse. Dimensions of a standard metal coal stove 50x80 cm and height 80 cm. It is recommended to make the wall thickness not less than 8-10 mm.

Making the device yourself

Bricklaying is a rather difficult job if you don't have the experience. Therefore, before starting construction It is better to ask a specialist for advice. When making a stove yourself, it is important to carefully follow all the steps and not change the selected design scheme.

Selecting a project, drawings

The choice of the furnace model is primarily influenced by the desired power of the device. The efficiency of the heater depends on the size of the firebox. Usually, coal combustion has a heat output about 500 kcal/hour. Therefore, the device is of standard size 110cm x 90cm suitable for heating a room of area up to 35 sq. m.

Photo 1. Drawing of a metal coal furnace. The device is small in size, it will fit even in small rooms.

Photo 2. Drawing of a coal furnace made of metal. All parts of the device are also indicated by arrows.

Materials and tools

To build a coal-fired oven, you will need fireclay bricks that can withstand heat. up to 1400-1650 degrees without cracking. To prepare the mortar, use fatty clay mixed with water and sand. To lay the outer walls, you will need solid red brick.

Doors and hinges, grate purchased at a hardware store.

The following tools will also be required for the work: hammers, trowel, rule, mortar shovel, hacksaw, grinder, building level, plumb lines, tape measure.

Stages of work

When choosing a place to build a stove, factors such as location of the chimney and dimensions of the room (in a large area it is better to install the equipment in the center).

Walls and ceiling in the selected area are covered with fireproof material.

It is better to think immediately about the place where the coal will be stored - to avoid fire hazards should not be placed in close proximity to the stove. It is also necessary to take into account that coal is very dusty and gets dirty.

A massive brick oven is being installed only on concrete foundation, which is not connected to the main one. Therefore, its location is best calculated at the stage of building the house.

To fill the foundation of the furnace, the following steps are performed:

- A pit is dug, not less than 50 cm deep (calculated based on the groundwater level).

- The bottom is tightly compacted and covered with a layer of wet sand.

- Lays a drainage layer of crushed stone 15 cm wide.

- The formwork is installed and concrete is poured.

- The foundation is left for three weeks until it has completely hardened.

- Waterproofing is laid - a double layer of roofing felt.

To prevent the weight of the stove from causing the foundation to become skewed over time, it is made quite wide.

After the concrete has completely hardened, they begin laying the masonry. The work usually lasts no more than one day.

Construction is carried out in a certain sequence:

- The first row is laid out, then the walls of the ash pit are erected. Before starting each row, it is recommended to first lay it out without mortar in order to calculate the correct position of the bricks.

- Installing the ash pan door (galvanized wire is used for fastening).

- The grate is being installed.

- The walls of the firebox are being erected. They are often made slanted downwards.

- They lay out the body (be sure to leave some space between it and the firebox).

- A cast iron door is installed.

- They are constructing the vault of the firebox. This is the most difficult part of the work, so when doing it, it is important to do everything exactly according to the scheme. The hole for the chimney is usually not closed with a damper, since the draft is controlled by the blower.

- They are building a chimney — the inside of the masonry is thoroughly cleaned of mortar and wiped dry with a rag. Perfectly smooth pipe walls will ensure the absence of ash accumulations and good draft.

When laying bricks, each row is checked using a building level and plumb lines. It is important that the thickness of the masonry joints does not exceed 3-5 mm.

Space in front of the stove covered with a metal sheet.

Possible errors and difficulties

To avoid mistakes when building a stove on your own, It is important to follow the steps exactly as per the diagram.

The most common mistakes that can be made are:

- Use of unsuitable materials — leads to rapid cracking of the seams. The brick also begins to crumble over time under the influence of high temperatures.

- Ash pan is not large enoughThe compartment quickly becomes clogged with ash and impairs draft, which can create a risk of carbon monoxide poisoning.

- Incorrect installation of fittings. All metal parts expand when heated, so if you don't leave a small gap, the metal will press on the masonry and cause cracking.

- Incorrect commissioning - causes cracking of masonry joints when heated.

To dry the device, let it stand from two to three weeks, then they start heating up small portions of fuel, gradually increasing the amount. Complete drying of the stove usually takes about a month.

Features of choosing coal fuel: stone, wood, brown, anthracite

For successful operation of the device, several types of coal are used:

- Stone - is black in color, hard to the touch, crumbles easily. Its moisture content 11-15%, heat transfer 5 thousand kcal/kg. It is poured into the firebox in a layer 12-18 cm, suitable for all types of devices.

- Woody - has a black shiny color with a blue tint, moisture 7-15%, heat transfer 7.5-8.1 thousand kcal/kg.

- Brown - has a light brown color, moisture up to 40%, heat transfer in the area 3.5-5.5 thousand kcal/kg. Universal, suitable for all types of heaters. Its disadvantage is the presence of harmful impurities.

- Anthracite — the most ancient type of coal, humidity 7%, heat transfer up to 9 thousand kcal/kg. Due to the high combustion temperature, it is only suitable for devices with specially reinforced combustion chamber walls. This is the most expensive type of fuel.

It is better to use pre-screen coal, so that no dust remains in it. Then gaps will form between the pieces, improving air convection, and the burnt dust will not form soot deposits on the walls of the firebox and chimney.

Useful video

Watch a video that demonstrates the design process for a wood or coal fired brick heating stove.

Conclusion

A coal stove is a reliable heating device that allows you to heat your living space efficiently. Coal It is used sparingly and has a relatively low cost. If necessary, it can be replaced with firewood and other types of solid fuel. Such versatility and ease of use make a coal stove the best choice for a country house or bathhouse.

Comments

I would also like to draw attention to the fact that a lot also depends on the quality of the coal. We took hard combustible coal - it is strongly baked by a crust, and all the heat goes down. Or you need to stir the fiery mass with a poker. We switched to long-flame coal - everything works great, no problems at all.

When we built such a stove at home, we used only heat-resistant brick for the firebox, lined it with solid red brick. And after laying the stove, we did not light it right away, but let it dry for about 20 days. The first day, we just burned a few chips. Then we heated it every day and added a little bit of fuel. We heated it like this for 10 days. Moreover, each time we heated the stove only when it cooled down completely, so it dries better and the clay solution on which the stove was laid becomes stronger and this also prevents cracking. If you light the stove right away, cracks will appear and they will start to smoke, then the whole stove will have to be rebuilt.