Not only do they heat, but they also provide the opportunity to cook food: fireplace stoves with a hob

The fireplace is a direct relative of the stove and a fashionable unit in modern homes.

Popularity is often enjoyed by combined structures with a hob and the fireplace itself.

This is not surprising, since The device has the following advantages: the ability to cook food, heat the room, and have an attractive appearance.

Content

Types of fireplace stoves

Depending on the materials used Furnaces are divided into:

- on metal;

- on brick;

- into combined ones.

It won't be difficult to build such a stove yourself, since all the components are available for sale, and the drawings can be found online. The main condition is adhere to construction principles and safety measures.

With a stove

Such stoves are usually a metal device with a hob and a decorative glass door. The inside of the structure is usually finished with fireclay bricks or special blocks of non-combustible material. based on asbestos or fireclay.

Such stoves are often manufactured in factories. The sizes of such stoves will vary depending on their productivity, which is expressed in kilowatts. The most popular models of stoves with a hob are Ferlux, "Cologne", "Oka", "Okhta" (Konig Feuer), "Narva", "Baikal".

Important! The power of any heating device in practice is selected based on the calculation 1 kW per 10 square meters premises.

One of the simplest steel designs of stoves with a hob and a fireplace - "Bayern". The product has a power 9 kW, which provides heating for the premises up to 100 square meters. The stove is made of sheet material and fireclay internal filler. The total weight of the structure is 126 kg.

With oven

Typically, such stoves are installed in a room that serves as a kitchen or recreation area for a large number of people. Since the size and features of each room always vary, a fireplace stove with an oven is made made of brick according to individual calculationsWhen building on your own, it is recommended to use ready-made schemes Dutch or Swedish ovens.

Photo 1. Brick fireplace stove with oven, made according to the Swedish scheme. The oven is located immediately above the firebox.

To avoid smoke premises, and also to ensure the correct operation of the device, it is necessary to observe the basic patterns when calculating the fireplace part of the stove design.

Reference. The ratio of the width and height of the firebox must correspond to the parameters 3:2, and the depth of the firebox opening should be leveled by 1/2 or 2/3 of its height.

Heating and cooking

A heat exchanger is a means of taking heat from its source, in this case from a furnace. It is usually a structure made of a pipe in the form of a lattice or serpentine, in which water circulates. It is mounted in the firebox or in the chimney. Such designs allow providing the premises not only with water heating, but also with hot water supply.

Important! If the fireplace stove is used not only for heating, but also for hot water supply, then the heat exchanger should not take more 10% of its total capacity.

DIY Kitchen Fireplace Stove

Before making a fireplace stove, you need to do the following: several preparatory activities.

Choice of project: with heat exchanger, hob or oven

The construction of any heating or decorative stove device is always accompanied by calculation of individual characteristics of the premises.

It is not practical to install a large structure in a small room or vice versa.

It is necessary to take into account that combined Stoves can have a hob, a water circuit for heating, a boiler, and also an oven.

Depending on the type of fireplace layout, stoves can be corner, one-sided or two-sided.

It is advisable to use for the kitchen one-sided furnace design and install it against the wall of the adjacent room to provide additional heating.

The front side of the fireplace can be decorated with a decorative door with glass or have a firebox made of fireproof bricks. For aesthetic purposes, a large glazed firebox opening is used, which also minimizes heat loss And the possibility of smoke filling the room.

Attention! When making a firebox with a glass door in the stove, only fireproof glass is used, which can withstand temperatures up to 800 °C. Ordinary glass begins to break down at a temperature over 260 °C.

Materials

To build a stove you need to use several types of bricks: solid refractory or fireclay, facing or pressed.

For decorative purposes, finishing materials such as:

- marble;

- fireproof tiles;

- decorative stone;

- decorative plaster.

For laying the firebox bricks, only a clay and sand-based mortar is used, which can be made independently based on the calculation 40 kg per 100 bricks. For the outer layer, it is permissible to use ready-made cement mixtures. The criterion for high-quality masonry is the thickness of the seam within 3-4 mm.

Important! When purchasing bricks and mortar, you should be guided by technical conditions of the furnace design.

Depending on the specific design You will need the following factory components:

- grate;

- reinforcing corners;

- firebox and chimney doors;

- hob;

- ash pan.

It is used as insulating materials. thick rock wool, providing protection in places where the chimney adjoins wooden building structures. The firebrick chamber and the facing layer are usually separated by non-combustible sheet materials, such as basalt cardboard or sheet asbestos.

Reference. To keep textured metal surfaces clean, it is recommended to seal them first. with masking tape or film.

Tools

Different tools are used to build the stove depending on the material from which the device is built. Each craftsman can connect additional devices made by hand for ease of work. To build a classic brick fireplace stove you will need the following tools:

- hammer-pickaxe;

- combination trowel;

- stitching for internal and external seams;

- level etc.

May be needed angle grinder for fitting bricks and cutting metal corners, sieve for sifting clay and sand, grout for internal firebox seams.

Selecting and preparing a place for a future fireplace

The choice of location for installing the stove is always agreed upon. with the general construction plan of the housing, possible soil subsidence near load-bearing structures is taken into account.

A medium-sized fireplace stove usually reaches a mass of 3-4 tonsTherefore, the foundation for such a structure must be strong and thick.

It is usually made of concrete, the ratio of sand to cement in which is 3:1. It is possible to use rubble stone as a foundation in order to reduce the cost of the process. However, such a foundation must be free-standing and also be 20 cm wider basic design.

Reference. The depth of the foundation is determined structural features of the soilIn most cases, it is enough to remove the soft layer of black soil and begin installing the reinforced concrete structure on dense clay soil.

Stages of construction of a device with a hob

The device is being manufactured in several stages, each of which has its own subtleties.

Pouring the foundation

Before pouring concrete, it is recommended to compact the bottom layer of clay, and also make a two-layer cushion of sand and crushed stone. thickness 50-100 cmReinforcement is used to prevent cracks from forming.

Bricklaying

The first rows of bricks are laid out along and across, alternating through each row. The installation of the ash pit door, the fireplace door and the stove firebox opening is carried out withfrom 2 to 11 rows. In the 11th row The hob of the stove compartment is attached.

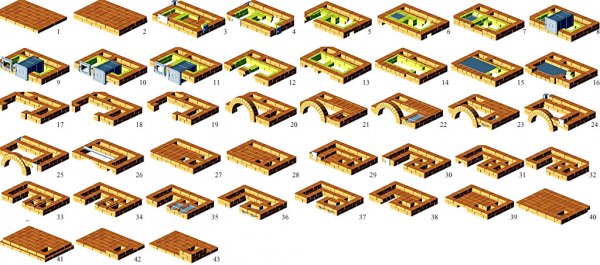

Photo 2. Option for laying out a brick heating and cooking stove. Contains 43 stages.

The chimney is being laid out from rows 23 to 29.

In this case The structure is made entirely of brick. The firebox is separated from the facing part by heat-resistant asbestos sheets. Additionally, it is necessary to cut valves from thick sheet steel, and also use metal corners as reinforcements for the firebox openings closing system.

Difficulties in construction

During the construction stage, problems may arise:

- Cracking of the foundation or walls. This happens because the solution releases moisture too quickly. To avoid cracking of the reinforced concrete foundation, first wrap it with roofing felt. Soak the bricks in water overnight before laying.

- Difficulty in fitting bricks. To avoid unnecessary work, you must first lay the brick on a prepared flat surface without mortar.

- Difficulty in installing metal elements. The firebox and ash pit doors have mounting holes that need to be used for securing with screws or wire.

- Complexity of installation of ceilings and valves. To strengthen the ceilings, an angle is used, and for the manufacture of valves, sheet metal with a thickness of 3 mm. Each metal part is adjusted separately. The valves are installed not on bare brick, but on pre-placed metal spacers.

Useful video

Watch the video, which demonstrates the development of a heating and cooking stove-fireplace project, and also provides the order of the device.

Compliance with calculations is a guarantee of quality

Only strict observance of the conditions project during the construction of the furnace ensures the correct operation of the structure. The construction of such a device will require from 3 to 5 weeks from the start of construction until the first ignition. This is exactly the period during which all solutions will fully harden.

Comments