How to build the most important part of the device? Do-it-yourself furnace firebox laying

Furnace firebox – one of its main elements, designed for combustion of fuel materials.

Any firebox must provide an oxygen supply to maintain the fire, complete combustion of fuel, the release of flue gases and the removal of ash.

Firebox design is determined depending on the type of furnace and type of fuel.

How to fold a stove firebox with your own hands

The furnace firebox consists of blower (ash pan) with a door, grate And combustion chamber (firebox) with a door.

Dimensions are determined based on the volume of firewood for simultaneous loading. The width of the firebox is equal to its door or slightly wider on both sides.

Height The firebox should facilitate complete combustion of the fuel, which is achieved by having free space in the chamber after loading the firewood. The recommended height 80-100 cm.

Reference. The depth of the furnace firebox must accommodate the combustible material along its length, There are no other restrictions.

The firebox is connected to the ash pan. by means of a grate. The latter is designed to supply air during combustion and collect ash. When installing the grate, it must be deepened below the level of the firebox door to prevent burning coals from falling onto the floor.

The firebox must have slopes in the direction of the grate to move ash into the ash pit. The gap between the masonry and the grate should be not less than 5 mmto prevent the brick from breaking due to the difference in expansion of the brick material and metal at high temperatures.

Selection of materials for masonry and ceiling, how to treat the structure

The structure is being manufactured made of red clay brick with facing (lining) refractory material. When choosing a brick material, it is necessary to pay attention to the fact that it is not overburnt or cracked. A high-quality brick suitable for stove masonry has smooth edges, sharp edges and a uniform color, when tapped, a clear, almost metallic sound is heard.

Attention! Sand-lime brick is not suitable for the construction of the device.

The following materials will be required:

- red brick — for walls;

- refractory and wedge-shaped (fireclay) bricks — for lining and forming the ceiling;

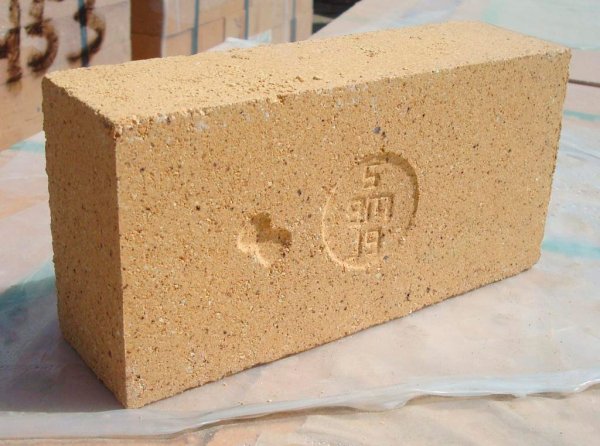

Photo 1. Firebrick used for laying the furnace firebox. Before using the material, it is necessary to make sure that it is intact.

- clay, sand, water — for solution;

- cast iron grate;

- doors firebox and ash pit;

- steel strips or wires — for fastening doors;

- asbestos sheet — for a fireproof gasket between the masonry and the doors.

For connecting stove masonry You can buy a ready-made mixture or prepare the solution yourself. In the high temperature zone, only red clay, sand and clean water are used. The quality of the solution depends on the viscosity, plasticity and fat content of the clay. Sand for construction must be free of dirt and impurities.

Preparing the tools

Making the design yourself will allow required set of tools:

- furnace hammer;

- trowel — for applying the solution;

- large capacity — for preparing a solution;

- building level — to control the correctness of the laying;

- measuring instruments - ruler, tape measure, square;

- plumb lines — to determine the outer contour.

How to properly cover the firebox and make a vault for a brick oven

To build a firebox, a certain amount of space must be determined. exact diagram the future furnace and laid foundation with a layer of waterproofing.

Before laying the bricks on the mortar, you need to assemble the structure without it - to precisely fit the bricks to size.

The construction looks like this step by step:

- Prepare a solution.

- First row They are laid on the foundation without gaps and form a base for the stove.

- On the second row The formation of the ash pan and the fastening of its door begin. To do this, mark the center of the future firebox and place the ash pit strictly under it. Flexible wire is passed through the holes in the door frame and its ends are twisted into a bundle. The wire bundles are fixed in the masonry layer.

- Form a contour blower and the place where the grate is laid.

- Fixing the firebox door using wire. The door frame is insulated with a gasket made of non-flammable material.

- Forming walls firebox and a vault with an opening for connecting the chimney.

- They are doing the lining firebox with firebricks.

Important! During construction You can't mix plain bricks with fireproof ones due to different expansion coefficients. When heated, such masonry will crack.

Bug fixes

When constructing a furnace firebox there are some common mistakes, which can be corrected during the work process:

- When forming the walls, the solution must be applied and level out with your hands to avoid cavities.

- Bricks must be laid during laying wet with waterso that they do not draw moisture from the solution.

- If one brick block is displaced, can't move it into the desired position. It must be removed, cleaned of the solution and laid again.

Cracks in the masonry due to temperature changes rubbed with solution. The cracked brick is removed from the structure, the area is cleared, it is moistened and a suitable brick is put back. If the door is not firmly fastened, it is removed, the seams nearby are disassembled, if necessary, the brick blocks are replaced with new ones.

Useful video

Watch the video, which tells about the process of laying a firebox for a brick oven.

Construction safety

Violation of the technology of stove laying at any stage of construction can lead to danger when using the firebox. The main mistake can be incorrect foundation laying.

Main signs of malfunctions, which arise when the foundation is laid incorrectly:

- The firebox vault is destroyed.

- The doors fall out.

- Burning coal is poured out.

- The brickwork cracks all the way across the entire area of the stove.

- The chimneys are falling into disrepair.

You can't heat the stove in this condition - there is a high risk of fire And poisoning of people by smoke gases. Breakdowns caused by an unsuitable foundation cannot be fixed. The entire stove will have to be dismantled and all the elements rebuilt.

Comments