The main decoration and protection of the firebox: which cast iron stove door does its job best?

The design of the furnaces provides for several types of doors. Firebox doors, as the name suggests, close the firebox. When using them during combustion sparks and embers do not fall out, which significantly reduces the likelihood of a fire.

In addition, thanks to the firebox door combustion efficiency increases and is supported even temperature inside the stove.

Content

What types of firebox doors are there for stoves?

The parts are made from steel, cast iron or glass, as well as from a combination of these materials. Cast iron, due to the properties of the alloy, are the most durable. They are available in various sizes, modifications, colors, etc. Therefore, it is not difficult to select a door suitable for specific conditions.

Modifications: one or two doors, with or without glass

The products are manufactured with one or two doors. Single-leaf doors open either to the left or to the right, and there are also those in which the opening side can be chosen.

Some doors are additionally equipped with dampers - devices for regulating air flow. They are convenient for fireplaces without a separate ash pit. There are stove portals made of cast iron, which include two doors: for the firebox and ash chambers.

Cast iron stove casting is made solid (voiceless) or with inserts:

- from cast iron (decorative, with bas-relief patterns and designs);

- from heat-resistant glass.

The latter option allows you to admire the fire. Doors with glass inserts are also called fireplace.

Important! Cast iron inserts are not only created for beauty. They add a touch of class to the product. additional strength, serving as stiffening ribs.

Form doors, as well as the shape of the insert, can be rectangular or arched. Moreover, they may not coincide with each other. For example, single or double-leaf rectangular doors with arched glass inserts are often produced.

Sometimes it is added for tightness heat resistant cordIt is placed at the joints.

Dimensions, weight and color of the product

The height and width vary quite a lot. There are also small doors, slightly longer 200 mm, and large ones, 450-500 mm and more, which are placed in fireplaces and stoves with baking trays.

Photo 1. Large cast iron oven door with the specified height and width. Blind casting, without heat-resistant glass.

Such casting quite heavy. Weight of the firebox door reaches several kilograms.

Carefully! Cast iron is not only heavy, but also fragile material. It must not be dropped during transportation or installation.

Common colors are - black and greyThey are compatible with all materials.

Service life

Thanks to its properties cast iron elements, unlike steel ones, not subject to corrosion and deformationTherefore, their service life is comparable to the period of operation of the stove itself.

Glass — is a rather fragile material, so a product made with it is most likely will last less. But glass is replaced if necessary. Manufacturer's warranties usually cover for 5-7 years.

How to choose the right model of cast iron stove door?

For brick ovens, it is advisable to select cast iron. still at the design stage. Although it is possible to install the elements in a ready-made heating device. For this need to determine the height and width the hole left for the door. If it is standard, it will be easier to select the necessary parts. Otherwise, you will have to make them to order.

Replace elements and in steel or cast iron stoves. This is done not only because of wear and tear, but also for aesthetic reasons. An option with an interesting pattern or glass insert changes the overall appearance.

Reference. The inserts are made 1 or 3 panes thick. When installing, a sealant is laid, leaving a small space for thermal expansion. Otherwise, cracks will appear.

At the same time factors such as are taken into account:

- type of fuel used;

- temperature conditions;

- dimensions of the combustion chamber.

Important and door parameters:

- form;

- number of valves;

- appearance;

- presence of a heat shield.

Fuel type

Fireplace doors are used with firewood (and also wood chips, brushwood and other wood fuel). Coal and coke require a closed space, since their combustion temperature is much higher.

Firebox size

Exists two size: external and landing. The latter depends on the width and height of the firebox. And the external size is the dimensions of the visible part, they are slightly larger than the landing ones.

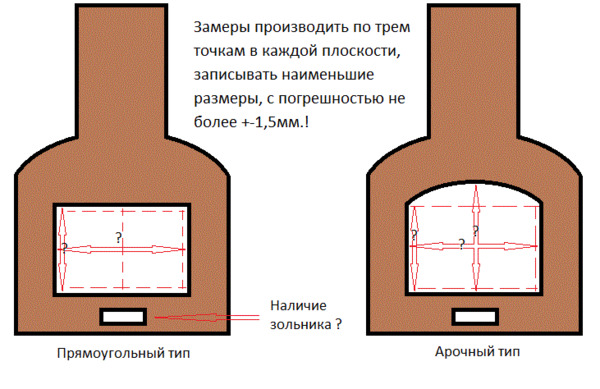

Before purchasing, measure the hole and use it to determine internal dimensions. Their they select accurately, A external ones can be increased by one value or another. If construction is only planned, the width and height are looked at in the project.

Photo 2. An example of measuring the furnace firebox before ordering or making the door yourself.

Temperature conditions

By degrees of adhesion Doors are divided into:

- hermetically sealed (with a special seal and clamping mechanism);

- non-hermetic;

- compacted (this is an intermediate option, without a heat-resistant cord, but with a special mechanism).

With the increase in the degree of tightness, the constancy of temperature conditions inside the firebox. This is especially important for cooking and baking devices.

Geometry of the product

The internal form must match the hole in the firebox. Most often it is rectangular, although it also occurs archedThe external form may differ from the internal one.

Number of flaps

Choice of one or two sashes depends on personal preferences. Single-leaf fireplace doors open best review on the fire. Bivalves are often more similar to vintage models.

Photo 3. Fireplace cast iron door model SVT 401, two leaves with inserts made of heat-resistant glass.

Presence of a heat shield

This shield is especially important in homes with small children or animals. The outer side of the door heats up less thanks to the heat-insulating layer, therefore it is impossible to get burnedGlass inserts are made in two layers with an air gap between them.

Reference. For additional protection, doors are sometimes fitted with removable handlesWithout them, the firebox cannot be opened, meaning the child will not have access to the fire.

Door exterior

It is better if the appearance of the stove elements is match in style among themselves.

Cast parts are produced as more simple forms, and with various inserts, patterns, bas-reliefs etc.

Maybe painting with heat-resistant paint. Most often, products are produced in black and gray flowers, but there are also others.

They look good glass insertsWith them, even an ordinary stove becomes somewhat similar to a classic fireplace. The frame is made in different thicknesses., depending on it, the overall appearance ranges from massive to light, “airy”.

But such options more fragile, tempered glass breaks even from a slight impact. Their harder to cleanIt is advisable to do this after each fire using special gentle means.

Carefully! Before cleaning the glass, make sure it is sufficiently it's cooled down.

Useful video

The video tells how to deal with one of the problems of fireplace stoves: carbon deposits on the glass of the firebox door.

Using Cast Iron Stove Doors

Firebox doors provide safe use and efficient operation furnace equipment. Iron casting strong and durable, fits almost any stove. But it is quite heavy and fragile, which must be taken into account during installation.

Glass models allow you to admire the flame. They are also installed in fireplaces. But glass breaks easily and requires additional care.

Comments

The glass door has a number of advantages - it is quite heat-resistant, fireproof and can withstand even higher temperatures than, for example, stainless steel doors.

Besides, it's very beautiful! The only downside is that such a door has to be washed often so that it retains its transparency. After all, soot and grime stick to the glass, so you'll have to look after such a door. But in all other respects, we're very happy.

In the bathhouse, you can also install a door with a glass window, but here it is still desirable that the firebox channel goes into an adjacent room, for example, into the dressing room. If the stove is heated from the bathhouse itself, that is, from the washroom, then water will definitely get on the hot door at some point, and the glass will simply crack and may even break. That is why I installed a blind cast-iron door on the stove in my bathhouse, and the air flow to maintain combustion is provided by the ash channel. Previously, when I installed a homemade stove, there was no ash channel, so I also installed a damper. And combustion can be regulated by sound, I do this by simply covering the ash pan or damper on the pipe until the hum subsides.

Moreover, our door area was quite large - 60 centimeters long and 50 centimeters high.

The door was ordered cast, with decorations, it weighed about 7 kilograms, but it was very reliable, solid. For reliability, a heat-resistant cord was laid when installing the door.

The color chosen was gray, asphalt, it looks very nice, which is also important.

I hit the glass with a scoop and a poker a couple of times, by accident, but there are no cracks. So the glass for stoves is made very strong.