Not a whim, but a necessary safety measure: how to cover an iron stove with bricks?

When the oven is in operation, its surface becomes very hot. For safety, the device is placed at a certain distance from the walls: not less than meters for metal structures and half a meter for brick.

But this arrangement is not always convenient, especially in small spaces. To avoid damage to surfaces and, especially, fire, put protective screens. They also promote gentle heating and protect against burns.

Content

What can you use to line a stove in a house?

Most often, stove screens are made made of brick or metalThese materials are available and do not require specialized equipment to work with them.

For laying they take refractory brick: normal red or clinker. Silicate is not suitable. The material is bonded with clay mortar (sometimes with the addition of cement or lime), which can withstand high temperatures without destruction.

It is better to choose from metals stainless steel. It is not afraid of dampness and does not emit harmful substances when heated, like galvanized. For fastening to the walls of the room, it is advisable to choose polished sheets, not matte. Then the heat rays will be reflected from the surface. This will reduce the heating of the walls, and the temperature in the room will rise faster.

Types of protective screens for furnaces

For air movement and better heating of the room, the protection is located a few centimeters from the walls. In the lower part of the structure are made gaps: gaps are left in the brickwork for this purpose, and metal sheets are installed on legs.

Reference. When using brickwork, the room warms up more slowly, but comfortable temperature lasts longer.

Such screens are placed on the sides facing the room. And to protect the walls, especially wooden ones, they are being sheathed.

Important! Side and front Screens are used only for metal stoves. Protection of nearby walls is also needed for brick structures.

Size screens depends on dimensions and power stoves. The material chosen also matters. At the same time, make the necessary gap between the screen and the stove, otherwise it will overheat.

Metal

Metal protection is installed at a distance not less than 1-5 cm from the stove itself. The distance to the wooden wall should be not less than 38 cm.

If the screen is attached directly to the wall, it is necessary isolate from the outgoing heat. Then the following scheme is used:

- At a distance of about 3 cm is laid from the wall thermal insulation layerTo create a gap, the material is not attached directly to the wall, but through the slats or metal pipes.

- On top of it metal is installed protection.

- The screen is made in such a size that it is higher and wider than the stove by a meter.

Advice. The air gap creates the possibility additional cooling.

There should also be a small distance between the floor and the screen. The protection is hung on the wall 3-5 cm from the floor. When floor mounting, the screen is installed on special legs. Another option is to make holes in the bottom of the sheet.

Brick around the iron stove

As a rule, the laying is carried out in half a brick. This provides sufficient protection, while not interfering with heating. Sometimes other options are used. When laying in a quarter bricks, the protective properties are reduced, and the heat becomes less soft, but the room warms up faster. But the distance to the walls should be greater than the minimum.

If the masonry is thicker, into a whole brick, the room will take longer to warm up. But this shield becomes a heat accumulator, that is, it gives off heat after the wood burns out.

Dimensions are calculated as follows:

- The height of the screen should be 20 cm more stoves. The masonry along the wall is sometimes extended all the way to the ceiling.

- Distance there should be a distance from the stove to the edge of the shield 5-15 cm.

For cast iron stove

Cast iron occupies an intermediate position in terms of heat-conducting properties. It heats up worse than steel, but better than brick, and cools down, respectively, longer than the first and faster than the second. That is why the protective screen is installed according to special rules. For it, a brick placed on the side, that is, the wall comes out to a quarter of a brick. In this case, less material will be needed, otherwise the technology is preserved.

How to build a stove screen with your own hands

To arrange protection, first of all it is necessary to choose a suitable schemeThen materials are selected, tools are prepared and work begins.

Selecting a scheme

When choosing a scheme, take into account the dimensions ovens, material walls and distance to them. The screen can be located near the wall or at a distance from it.

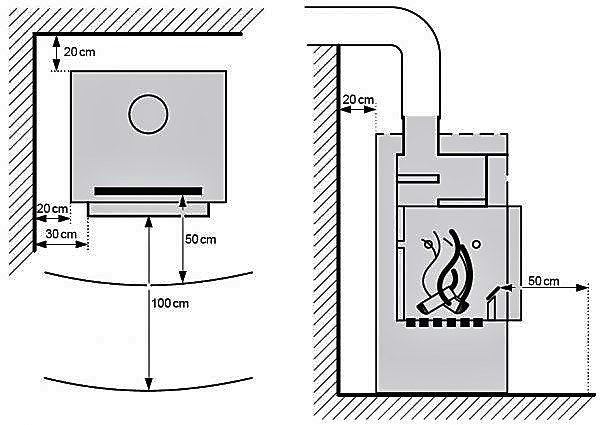

Photo 1. Scheme of installation of the stove in the house, according to fire safety regulations. The necessary distance is indicated.

The brick version requires a long warm-up, but creates a more comfortable atmosphereOver time, under load, bricks can begin to fall out, so the metal version is considered more reliableAnother advantage is that it requires less space.

Important! They are installing a brick screen on the same basis, as well as the stove. Therefore, it is advisable to provide for it in advance. If the base does not protrude beyond the stove enough, a steel screen is used.

Preparation of materials

For brickwork, fireproof bricks are used: red solid or clinker. Silicate material is not suitable for these purposes. It is easier to find out how many bricks you will need if you already have a small number of them. To do this, lay out material in one layer around the stove, leaving a small gap. Most likely, it will work square 3x3 or 4x4If there is no building material at all, you will have to perform these calculations based on the dimensions of the selected type of screen.

This is how they determine how many bricks are needed for one row. Then the required number of levels is calculated. For this, the height of one brick and the entire wall is taken into account. Often there are 11-12 rows, although sometimes more or less is required.

Before you start laying bricks soak in cold waterHalf an hour or a little more is enough for this.

It is used for masonry clay mortar. Clay is mixed with sand in proportion 1 part clay to 2-3 sand. Sometimes some of the clay is replaced cementReady-made mixtures are sold, which are easy to dilute with water.

The quality of the solution is checked in this way: rake the solution to the side with a trowel, it should hold the track, but not tear. If the solution spreads, add more mixture, if it is too dry - water.

For a metal screen, take:

- sheet metal (preferably stainless steel);

- screws or screws;

- Grover washers.

You will also need thermal insulation materials:

- basaltic cardboard;

- asbestos cardboard;

- minerite slab.

Dimensions steel sheet may be smaller than the future screen. Then their quantity is calculated in such a way that it is possible to lay them with an overlap. The amount of thermal insulation is determined for flush installation.

Advice. It is better to take materials with a little in stock.

Tools

For production brick shield you will need:

- trowel;

- construction mixer;

- level;

- container for solution;

- fishing line or boards for marking.

For steel structure you will need:

- drill;

- screwdriver;

- metal shears;

- roulette;

- level.

Once you have selected the desired design and prepared the materials and tools, begin construction.

Brickwork

Before you start working soak brick for 30-40 minutesWhile it is soaking, mark the outline of the building. It is convenient to use a stretched fishing line or boards with bricks or bars underneath.

If the floor is wooden, be sure to put it under the future masonry thermal protectionIt is fastened with self-tapping screws or a special adhesive.

First row placed on the solution starting from the corner. Next It is started from the same corner, but half a brick is laid so that the seams do not coincide.

Above the following levels are laid. For strengthening, between them are laid narrow strips of reinforced meshThe evenness of the masonry is checked with a level both horizontally and vertically.

In the second or third row make holes for cold air. To do this, put a brick at half the distance from the previous oneThen put another half or a whole one, and after that, continue as usual.

Such gaps are made on both sidesIf the oven is powerful, they make more of them.

Don't forget to leave openings for ash pan and firebox. The opening is covered from above. A steel angle is used for this.

Important! While the solution is not dry, to drown stove it is forbiddenIt must dry at a constant temperature.

Installation of a metal shield

Mark the location of the screen on the wall. It should be at a distance of 3-5 cm from the floor, and the height and width are a meter larger than those of the stove.

It is placed on the wall with a small gap heat-insulating materialFor this purpose, you can use special ceramic bushings, slats or tubes.

A metal sheet is installed on top of it. If its dimensions are smaller than the required area, put it down metal overlappingFirst the bottom sheet is attached, then the next one, etc.

For installation screws or wood screws and washers are used. Only the top fastener is screwed in until it stops. The others should be more elastic to compensate for thermal expansion.

Photos of brick lined stoves

Photo 2. A metal fireplace stove lined with brick on three sides – safe and beautiful.

Photo 3. Iron stove, completely enclosed. The masonry has holes for free air circulation.

Photo 4. An iron stove of the Buleryan type requires a brick protective screen on at least three sides.

Possible difficulties during lining

It is difficult to arrange the masonry accurately calculate the places for the firebox and ash panIt is convenient to lay the bricks without mortar and check how the device opens. Then, having made the adjustment, lay the bricks finally.

Useful video

A video showing how to fold a brick protective screen for a stove with a remote firebox.

Application

The furnace screen is designed to protect against excessively high temperatures. Most often it is made of brick or metal. The protective screen surrounds the stove, like cladding, or is located on the sides that are close to the walls. It covers the stove to the top or even higher.

When using it characteristics are improved stove, the risk of fire and burns is eliminated, the room is warmed with a softer and more useful heat. The required temperature is maintained even after the end of the firebox or the device is turned off.

Comments