Not only reliable, but also beautiful: what do you need to know when making a glass oven door with your own hands?

Oven doors are widely used and are made from a variety of materials: cast iron, metal, panoramic glassThey are found on the firebox openings of all stoves and fireplaces.

By opening the door you can add more firewood, regulate temperature, and watch the burning logs through the glass.

Stove doors with glass

Glass doors for a fireplace or stove come in the following types:

- circular;

- segmental;

- flat (thickness of one glass).

Doors for stoves and fireplaces, where glass is the main or secondary material, are especially widespread.

This is due to a number of qualities:

- fire resistance;

- security;

- ease;

- aesthetics.

Pros and cons

A good quality panoramic glass allows you to see what is happening inside the firebox without it getting hot. Such a door absolutely safe. Sequence fireproof. Unlike the same stainless steel, panoramic glass does not deform at high temperatures. Many homeowners find cast iron or iron elements in the interior to be rough. This cannot be said about panoramic glass, which harmonizes with any decoration.

Of course, such a door has cons. The first of them is - fragility. If you accidentally hit the stainless steel door with a poker, it will not affect it in any way, but the glass will shatter. In addition, after each kindling soot cleaning required, otherwise the glass quickly ceases to be aesthetic and transparent and takes on a sloppy appearance.

Photo 1. Cleaner "HG" for heat-resistant glass, 500 ml, is suitable for removing soot and carbon from a glass door.

Heat-resistant glass is capricious to clean abrasive detergents are not suitable, as this will easily damage the polished surface of the screen.

Metal doors

Metal doors are widely used because cheapness, ease of installation, convenience and fire resistance. At the same time, they ensure absolute tightness of the structure. If the door is made poorly and lets oxygen through, this will sooner or later lead to a fire. Therefore, the stove maker, when installing the firebox doors, constantly checks level of tightness. Only this guarantees quality work.

Cast iron shutters

Cast iron valves are used primarily in furnaces, for example, baths, and not in fireplaces. Their undeniable advantages include high fire resistance, resistance to temperature changes.

But such doors will not please those who like to watch the dance of sparks and burning wood. Cast iron looks not aesthetically pleasing, inconvenient to work with, heavy, less durable, than metal structures.

Making a glass door for a stove with your own hands

The basis for the firebox door with glass is used metal (usually stainless steel or cast iron). According to reviews from experienced stove makers, cast iron is preferable: it is durable, not afraid of high temperatures, easy to clean, and is strong. Stainless steel when heating the stove gets very hot, is not suitable for withstanding open fire and warps quickly.

Tools and materials

To work you will need:

- Bulgarian;

- sheet metal;

- heat-resistant glass;

- construction gloves;

- masonry composition;

- welding machine;

- level;

- fiberglass.

When choosing panoramic glass, you need to remember its fire resistance.

Stages of work

The door installation work consists of the following stages:

- execution drawing the entire structure;

- cutting out blanks made of metal for the frame and sash;

- manufacturing framework;

- fitting glass frames;

- baiting of canopies;

- welding frame parts, installation of glass element;

- installation canopies, latches and handles.

Attention! The task is within the power of those who have at least basic experience in working with a welding machineIf you have never welded before, delegate this task to a professional.

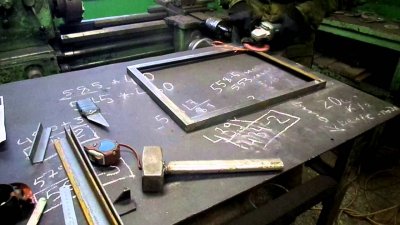

Creating a blank

At first measure the size of the fireplace. The corner is cut out according to the established parameters.

The frame is placed on a sheet of metal, is being marked circuit. After checking all the measurements, the workpiece cut out using a grinder or cutting wheelThis will be the lintel for the door.

The glass element is attached by means of bolts screwed into the corner along the plane. They will not allow the window to fall out, but at the same time do not interfere with thermal expansion.

The door fasten to the lintel by means of canopies.

Attention! Before installation, glass insert comes out of the frame!

Door corner checked with a plumb line. For this purpose they use three-millimeter wire, previously burned and softened in the fire. It is inserted into the frame opening, folded in half and tightly twisted so that no rings form at the ends. If they cannot be avoided, the wire is flattened with a hammer.

A completely blind casement, without a window, is less common. It is made using the same principle, but without a transparent element. When the frame is ready, the future casement is marked and cut out, making sure that it lies on the opening. overlapping.

Fastening to the base

You can't just attach a frame with a door to the brick. You'll need special niche. First, the contours are marked on the masonry, then a recess is cut out with a diamond wheel.

Most often used for fastening metal anchors. Before attaching the door to the base, check whether it opens easily. If it opens with visible effort, the workpiece needs to be modified.

The lintel frame is wrapped with asbestos cord, then coat with heat-resistant glue. The cord will have to be pushed into the recess along the perimeter with a screwdriver.

Reference! Free air flow into the firebox is required. The preferred design is with oxygen supply regulator.

Before directly installing the door on the masonry, the base is painted fire-resistant paint. When working it is necessary respirator and glasses, since the composition is toxic and easily gets into the eyes and respiratory tract. The paint is applied in several layers to mask welding flaws.

Useful video

Check out the video to learn how to make your own glass door.

How long will a glass firebox door last?

When making a stove door yourself, you need to be unhurried and careful in your work. The main thing is to follow two rules: continuous air supply into the firebox and at the same time chamber tightness. A properly executed design will last for more than a dozen years.