We build for centuries! The correct proportions of clay and sand for laying a stove

Clay mortar for stove masonry is made from natural materials.

Clay has the same coefficient of linear expansion as bricks made from this raw material.

The solidified clay mixture is a strong and durable material, it does not deteriorate decades.

Content

Composition of clay mortar for laying stoves, proportions

The solution is used for laying the stove itself, but mixtures based on it are better suited for the chimney. lime and concreteThey are less susceptible to cracking from the effects of furnace gases and hot smoke.

Photo 1. Clay mortar is applied to the bricks, thus connecting the blocks.

Clay mortar contains two main ingredients - clay and sand. Sometimes, for strength, table salt (the consumption of which from 80 to 250 grams per bucket of solution), cement (0.75-1 kg per bucket) and heat resistant glue (according to the instructions on the package).

Reference. The amount of clay in masonry mortars depends on its quality and is from 20 to 100% volume of the mixture.

It costs a hundred bricks 30-36 dm3 clay-sand paste (three buckets). The thickness of the seams in the masonry is 3-4 mm, but no more 5 mm.

Recommendations for production

They sell it in construction stores ready-to-use packaged mixes for masonry. They consist of high-quality clay mixed with fine-grained sand.

To make mortar for masonry with your own hands, you have to take sand and clay from the area. Stove-makers sometimes use several types of raw materials from different areas. In order not to make a mistake and not to bring unsuitable material, it is useful to consult with local craftsmen.

Which clay to choose and how to determine its quality

Clay is a finely dispersed rock with a particle size of thousandths of a millimeterThe chemical formula of the main mass of the rock is Al2O3. This material is very plastic, pliable to mechanical action, the clay paste will withstand the finest molding. The volume of the raw material swollen from water increases up to two times.

The composition of clays includes iron and other metal oxides, plant remains, hydrocarbons, carbonates, chalk particles, iron sulfide. Impurities give this rock its different colors.

Fatty clays are finely dispersed, they highly plastic. When drying, the raw material cracks strongly, although the dried pieces have high strength. Such rocks contain from 3 to 15% sand.

Lean (sand-rich) clays, on the contrary, have low plasticity. When dry, they become fragile, disintegrate due to the high content of granular material and are similar in composition to sandy loams. They contain more than 80% sand.

Clays normal (average) the composition does not crack after drying and does not crumble under mechanical impact.

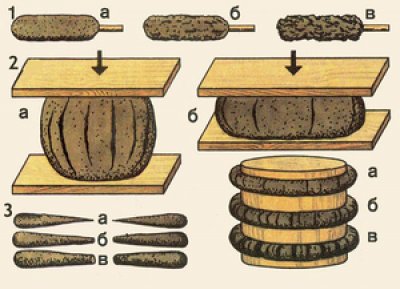

The quality of raw materials is determined empirically. There is Several ways to determine the fat content of clays:

Method 1. From clay that has been soaked 24 hours ago, roll sausages-strands up to one and a half millimeters thick and up to 20-22 cmThey wrap a cylindrical object with a circumference of about 50 cm.

Fat, viscous clay stretches smoothly and easily without breaking. When the raw material has a normal composition, small cracks will appear on the tourniquet from stretching. A tourniquet made of lean clay mass will break when stretched.

Method 2. The dry material is filled with water and softened to a state liquid dough. The soaked mass is stirred with a wooden spatula and lifted upwards. Fat, viscous clay forms a layer on the spatula that strongly sticks to the wood. Normal clay falls off the mixer in chunks. Lean clay falls off completely, leaving only moisture on the mixer.

Method 3. On a freshly rolled clay sphere press with a boardIf the material has a fatty composition, cracks will appear on the sphere when it is flattened by half the diameter. On raw materials of normal composition, cracks will appear when flattened by a third of the diameter, on lean clays - when lightly flattened.

Method 4. The clay is soaked and kneaded. The amount of water should be small, as for pelmeni, elastic dough. A sphere with a diameter of 40-50 mm and make a flatbread thick 25-30 mmThe samples are dried for a couple of days.

- Cracks will appear on oily, plastic clay after drying.

- If the raw material has a normal composition, there will be no cracks.

- On lean clay saturated with coarse impurities there will be no cracks, but the ball will be fragile and will crumble under mechanical impact.

If the ball is dropped from meter high, fat (and normal) clay will not break. A ball molded from lean clay, saturated with a coarse fraction, will break into many pieces and grains of sand.

What kind of sand to prepare

Only fine sand with a grain diameter of up to 1.5 millimetersFor laying, sand of mixed composition (quartz, feldspar, pieces of other minerals, mica) or pure quartz sand is suitable.

Removal of impurities

Almost all quarry clays and sands contain impurities and require cleaning. Residues are removed from raw materials in various ways plants, roots, grains of sand, pebbles, pieces of crushed stone.

How to remove impurities from clay

Impurities significantly impair the quality of the masonry. The cleaning of raw materials is carried out in three stages:

- manual selection plant remains, roots, rubble, pebbles;

- sifting through a metal sieve with hole size 1.5 mm;

- soaking clay;

- rubbing through a fine-mesh metal sieve.

Photo 2. The process of sifting clay through a metal sieve. You need to press it with your palm so that all the particles pass through the mesh evenly.

In practice, to clean clay for mortar, craftsmen do without the labor-intensive process of soaking the raw materials.

How to remove impurities from sand

Sand is considered prepared when water passing through it will become cleanTo prepare the material, you need to complete next steps:

- From sand manually selected plant remains, roots, large stones.

- After a rough selection of the material sift through a metal sieve with cell size 1.5 mm.

- Sand placed in a bag (or net) from burlap and rinse with running waterA hose is used for flushing, and water is supplied under pressure.

Soak

Dry pre-packaged clay purchased from a store should be soaked. For work you need wide capacity (trough), tank or other vessel:

- The container is filled 80% clay.

- Capacity up to the sides fill with clean waterso that it completely covers the material.

- After 24 hours, the solution is stirred.If there is not enough water, add more and leave the clay to soak for another day.

- Soaked material transfer to another container.

Clay mined from a quarry is soaked in the same way. If the material is wet, it is also soaked, since it usually does not contain enough water.

How to knead correctly: step-by-step recommendations

There are several ways to mix clay mortar for masonry. It is prepared in troughs, tubs, metal tanks, palletsIf the volume of work is small, the ingredients are mixed in a regular bucket. Less often - in a special shallow pit and on boards.

Preparation of clay-sand mortar

The stove-maker measures out the required amount of mixture components - clay, sand, additives (cement, glue, salt) and pours them into separate vessels. The amount of each ingredient is calculated in advance and determined during the experiments. Next The work is carried out in the following order:

- Clay is poured into the container and fill it with water for 24 hours. Some stove-makers advise soaking this raw material 2-3 days.

- Clay stir with a wooden stirrer, then - with a construction mixer.

- Into the tub adding sand.

- The solution is stirred (first with a spatula, then with a construction mixer), add a little water if necessary.

- If planned, in a sand-clay mixture introduce additives, which increase the strength of the masonry.

How exactly is clay diluted, the ratio with water

Clay is poured into a trough, fill the container with water to the brimThe next day, the material is mixed and rubbed through a metal sieve. 75% dry raw material takes 25% waterThe ground clay paste is immediately used for laying.

Attention! It is better to take for kneading "soft" water with a low content of calcium carbonate and other salts. Salts appear on the walls of a dried-out stove, and in the absence of whitewash, they spoil its appearance.

Methods of quality control

Stove-makers check the quality of the solution in the following way: they take the freshly prepared clay paste on a metal construction trowel (trowel) And turn it over. A solution of normal composition stays on the trowel without falling. If there is a lot of clay in the paste (fat composition), then it sticks tightly to the trowel in a layer of thickness 3-4 mmIf there is a lot of sand, the solution immediately falls off completely from the inverted shovel.

To check the quality of the material ready for work, you can use the same methods as to determine the fat content of raw clay (molding and drying balls, flattening a ball with a board, testing its strength by dropping it from a height of one meter, pulling out bundles).

What to do if the mixture has dried out

To prevent the clay paste from drying out, store it in a covered container. with a wet cloth. If glue and cement were not added during mixing, the material can be returned to working condition. To do this, the dried mass smash into pieces with a hammer and fill with water. After a day it will soften. If necessary, the pieces are crushed with a wooden tamper. After all the pieces have softened, the solution is mixed with a mixer.

Photo 3. Dried clay in a deep container. It can be mixed again if no glue or cement was added to the solution.

What to do if the mixture is too thick or too thin

The consistency of thick clay can be changed by adding water to it and mixing the mass with a stirrer, then with a mixer. If there is excess water in the solution, you can get rid of it in two ways:

- Give the solution stand still and release excess water to the surface, and then scoop out her.

- Separate the water on a sloping tray. Portions of clay are placed on an inclined surface. Excess water will flow out of it. The squeezed material is placed in another tank (trough). In practice, if there is excess water, more dry clay is added to the trough and left for a day to swell.

How long does it take to dry out heating structures?

The clay masonry takes a very long time to harden, the brick absorbs moisture and practically does not give it back. Therefore, drying the stove takes place in 2 stages.

Natural drying takes at least five to seven daysAt this time, the damper, door and ash pit should be open in the oven.

It is recommended to direct the fan towards the mouth of the firebox. 5-6 days natural drying, the solution hardens only on the surface of the stove, firebox, chimney.

Forced drying is carried out for 9-10 days in summer And 3.5-4 weeks in winter.

The drying time depends from the design of the stove, its size and the time of year. In the oven daily (2 times a day) burn several thin logs.

Drying is considered complete if after 3-4 hours After firing, there is no condensation on the inner surface of the door or on the damper.

Useful video

Watch the video, which shows the entire process of making clay mortar for laying a stove.

Comments

It is faster to simply sift the sand through a large mesh screen. Then sift it through a fine mesh screen.

It is also best to wash the sifted sand not in a bag, as the author of the article advises, but in a sieve with very small cells. The washing process in this case eliminates the need for water under pressure.