To prevent the floor in the bathhouse from suddenly disappearing from under your feet: how to make a reliable foundation for a stove with your own hands?

To ensure reliability and stability In order to maintain the design of the furnace and prevent the loss of its original appearance and functionality, it is necessary to build a reliable support.

Without a properly constructed foundation, brickwork can become warped over time, requiring large repair costs, so It is worth thinking about its design and layout in advance.

The foundation should be installed with sufficient or a small margin of safety.

Content

Types and schemes of foundations for different stoves: Russian, bath, metal

Before choosing the scheme and type of foundation, you should decide on view of the future oven - bath, Russian, fireplace or metal.

The latter practically does not require additional support; it is enough to protect the surrounding area from fire.

Bathhouse the oven is usually small in size and has a small weight. It is worth dwelling on in more detail Russian the stove and the support for it.

It takes on average about one and a half thousand bricksOne brick weighs about four kilograms, total weight the design without taking into account the solution will be six tonsThere are also lightweight options, when the stove weighs up to one and a half tons.

Important! The depth of the foundation and the choice of type are influenced not only by weight of the oven, but also soil type plot.

Monolithic

The simplest option for building a foundation, which is reinforced slab, placed in the base of the stove. The load on it is distributed evenly, but the overall weight of the stove should be taken into account, especially if it is made of brickwork. On average, such slabs can withstand the weight up to 800 kilograms per square meter. It is worth considering that this figure also includes the weight of the stove itself. For a full-fledged Russian brick oven, this option will be inappropriate.

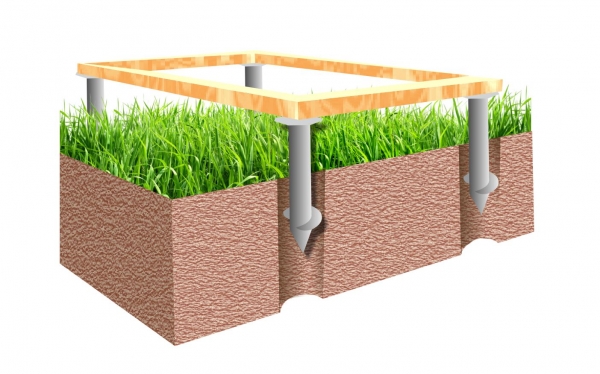

Pile

This type is four supports, screwed into the ground, on which it is laid reinforced concrete slab. It is suitable for highly heaving and loose soils, reliably holding the structure. Piles diameter 20 centimeters, length 170 centimeters capable of withstanding under the grillage up to 2-2.5 tons loads on each.

Photo 1. Diagram of a pile foundation: the supports are screwed to the depth of soil freezing and securely hold the structure.

Ribbon

The ribbon type is iron-reinforced concrete shaped like an inverted T. It refers to budget options, used for filling concrete not lower than grade 200The disadvantages include: high susceptibility to groundwater influence, and also fragility on highly heaving soils. It is practically impossible to install such a foundation on a rocky one.

In addition, if a strip foundation is also laid under the house, the base for the stove should be place separately at a minimum distance fifty centimeters from the mainOtherwise, the structures will be interdependent, and not only the stove, but also the house may become skewed.

Screw

This type is similar to the pile type, with the difference that during installation, screws are screwed in. propellers with blades, which securely hold the soil. The concrete solution is poured directly into the piles, after which it is allowed to harden.

Since iron is subject to corrosion, it is possible for such a foundation to retain its properties for fifty years old with slight deviations up or down. The most durable is metal coated with a special polymer.

Installation of this type possible only until the walls of the house are raised. It can be carried out either manually using a drill or using special equipment. Suitable for heaving soils with low stability.

Columnar

Economical option that is ideal for soils consisting of coarse and medium sands. For water-saturated, peaty, clay soils, this option won't fit. Columnar is supports dimensions forty centimeters on each side. They are placed around the perimeter of the building, and can be installed on top. concrete slab.

Foundation for a brick stove in a bathhouse or in a house with your own hands

This procedure consists of four main stagesIt should be noted that the choice of the type of foundation is also influenced by the financial capabilities of the home owner. However, it is easier to save on the construction of the stove itself than on the foundation.

Selecting a scheme

Depends on the dimensions and material of the future furnace. The choice is made based on:

- Soil. For the sustainable sand, stone-sand strip and columnar foundations are suitable. For peaty, water-saturated, highly heaving soils, you should choose screw or pile. For rocky A monolithic slab would be ideal.

Photo 2. Soil examination at the site of future construction: a pit was dug for visual examination.

- Weight of the furnace and material manufacturing. It is not necessary to lay a foundation for a metal stove, since its average weight is up to 200 kilogramsA foundation will need to be installed under the brick oven, the depth of which also depends on the level of soil freezing and the number of bricks.

Advice. The perimeter of the foundation must exceed the dimensions of the furnace by 6-10 centimeters.

Materials

For bookmarking foundation depending on its type will be required:

- Concrete;

- Sand;

- Iron brick;

- Rubble stone;

- Roofing felt or other waterproofing material;

- Asbestos sheets;

- Crushed stone;

- Gravel;

- Reinforced concrete slab;

- Screw piles.

Preparing the tools

For construction the foundation will require:

- Shovels for digging a pit;

- Concrete mixer;

- Trowel and others.

How to make the foundation itself: instructions

For strip and monolithic the order of work looks like this:

- Preparing the excavation pit up to one and a half meters deep. Width it should be, as a rule, ten centimeters wider than the future foundation on each side;

- Creating a seal sand pillows. It can be alternated with gravel (the equivalent of gravel is broken brick, rubble stone);

- Fill everything concrete sole (up to five centimeters), wait until it hardens;

- Install waterproofing material - roofing felt. You can use bitumen mastic or liquid rubber;

- To erect formwork made of plywood or OSB boards, put inside reinforcing mesh;

- Fill with concrete. Wait until it hardens completely.

Ready to use such a foundation is up to three weeks depending on the quality of the concrete and the presence of plasticizers in it. When choosing a strip foundation, a trench is dug around the perimeter of the future building, and not a common pit.

Important! You shouldn't touch the concrete. before it has completely solidified. This will allow you to avoid damaging the foundation during the construction phase. The hardening concrete must be wet regularlyto avoid cracks.

Pile the foundation is erected using the following technology:

- The pit is being built up to twenty centimeters deep (the slab will be placed in it);

- Around the perimeter create small pits the same depth for installing piles;

- Screw in the piles into the holes, maintaining a strictly perpendicular position;

- Cut off the tops on one level.

- The next step will be installation on top of the piles reinforced slab. It can be replaced by independent installation of formwork and reinforcing mesh with subsequent pouring concrete mixture.

Photo 3. The foundation for the brick oven is ready, you can start laying out the first rows of the heating structure.

Possible errors and ways to correct them

If the masonry of the stove itself or the chimney is destroyed after construction, problems appear through cracks, the problem is in the incorrectly laid foundation. In this case, partial alteration is impossible, since subsequently the restored areas will again be subject to the same damage.

Carefully! The finished oven not subject to partial repair, if errors are found in the base filling.

To fix the situation it will be necessary completely disassemble the oven and re-install the foundation, which leads to significant costs of both time and money.

Useful video

A video showing how to prepare a foundation for a brick sauna stove: how deep to dig, what to fill it with, how long to wait for it to harden.

You can't do without correct calculations

From the foundation the durability of the entire furnace depends, its proper functioning. It should carefully weigh all the pros and cons each type of foundation, calculate the weight of the future building and install a support with a safety margin. In addition, the total weight of the furnace should include the mass of the solution.

In this case better safe than sorry and install a stronger and more expensive support than redoing the entire stove when it cracks

Comments

And when installing a screw foundation, you still can’t do without a monolithic slab under the entire area of the stove. Therefore, using screw piles is an unnecessary waste of money.