Water and rod heated floors for heating a house are one of the most economical ways

You are viewing the section Warm floors, located in the large section Heating.

Of all the surfaces in the room, a person comes into contact with the floor, its heating creates special comfort and in the best way provides the required temperature in a private house.

Content

Rod warm floors for heating a private house

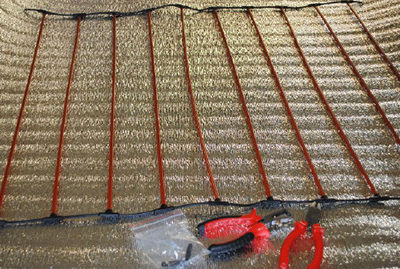

Rod electric floor is a system that includes rods made of a special alloy (usually carbon) and electric wire.

The structure is placed under a cement screed or in tile adhesive and operates on the principle of infrared heating.

The finished kit resembles a rope ladder in shape: between two cables heating elements are fixed in parallel at the same distance. The distance between the tubes is about 10 cm, maximum length of the set – 25 meters.

The principle of operation of carbon reproductive systems

In terms of the operating principle, rod floors are similar to film heated floors, heating occurs by emitting infrared wavesThe rods used are usually made of carbon, silver and copper and when voltage is applied they begin to heat up.

According to manufacturers, carbon floors are more economical (up to 60% compared to some other options). There are variants of systems made from other materials that operate on a similar principle.

The design is based on a parallel connection, and if individual rods are damaged, the others continue to operate effectively. One of the components of the kit is a temperature sensor that allows the system to regulate itself.

Photo 1. Carbon heating system in a private house with parallel rods and self-regulation function.

When the desired level is reached, the rods are switched off. This saves electricity, ensuring a stable temperature in the room. Electricity consumption one sq. m. carbon floor varies from 20 to 160 W and depends on the number of rods.

Peculiarities

The layout is simple, done in parallel rows. Near the wall One of the cables is cut, and the structure is unfolded on the second, and the installation continues in the opposite direction. Placing the structure under the screed or tile adhesive makes it difficult to dismantle in case of breakage. The system's functionality is checked in the presence of an electrician before laying cement or tiles.

Advantages

The advantages of such systems include:

- uniform heating of the entire area of the room, unlike heating with radiators of centralized heating systems;

- cost-effective operation;

- fire safety (protected from overheating by a self-regulating system);

- ease of installation and assembly;

- light weight;

- the ability to place heavy objects on the floor (convenient when rearranging cabinets and other items);

- integration into the design of a “smart” home;

- long warranty periods (approximately 20 years);

- maintaining functionality in the event of partial failure of individual elements.

Cons

Users and experts highlight the following disadvantages:

- breakage of rods during operation;

- non-repairability of floors due to laying in cement;

- high cost;

- "wet" installation method;

- poor mobility – transfer to another room is excluded;

- installation requires the presence of an electrician;

- systems of some manufacturers in fact, they consume more electricity than stated.

Scope of application

The rod system is suitable for use in various premises:

- residential;

- public;

- sports;

- office;

- warehouse;

- with high humidity, such as bathrooms (with high-quality installation and proper waterproofing);

- winter greenhouses.

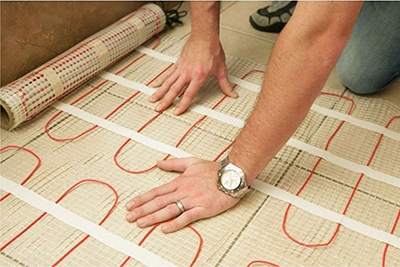

Photo 2. Ceramic tiles are laid on top of the carbon heated floor in the room as one of the covering options.

Carbon floor covering options:

- laminates;

- linoleums;

- porcelain tiles;

- ceramic tiles;

- materials made of natural and artificial stone;

- carpets.

Installation of such a floor in tile adhesive is especially convenient with simultaneous laying of tiles. Special adhesive for warm floors is used. The thickness of the adhesive with the tile should be more than two centimeters.

Preparation for installation and accessories

As a rule, a ready-made underfloor heating kit is used, as well as a number of devices and tools.

The factory kit may include:

- mat with carbon rods in a roll;

- connecting cables;

- other connecting elements;

- end caps;

- corrugated tube with probe;

- instruction.

Devices, materials and tools used for laying the floor:

- reflective material (installed under carbon rods);

- temperature controller;

- temperature sensor with tube;

- pliers;

- crimping tool;

- construction knife and scissors;

- hair dryer;

- scotch tape and other.?

Installation

Installation stages:

- Selecting a surface for installation.

- Selecting the location of the thermostat (convenient to install near the switch).

- Surface preparation.

- Making a groove in the floor, where the temperature sensor will be located (cut a groove).

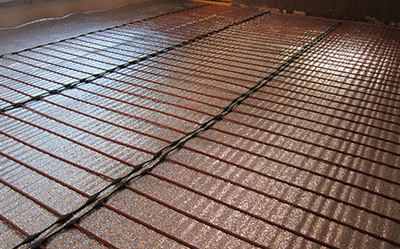

- Installation of heat-reflecting material using glue or tape.

- Laying out carbon flooring with fixation. Start from the connection section to the thermostat. At the turnaround point one of the wires is cut in the middle between two rods, the strip is turned for laying in the opposite direction. The mats are fixed to each other and to the heat-reflecting surface with tape.

Attention! Crossing carbon rods unacceptable.

- Electrical installation of the mat is done with a hair dryer using connecting wires, end and other elements. This stage is discussed in detail in the video instructions for floor kits.

- The connection of the thermostat is carried out according to the diagram.

- In the heat reflector in a checkerboard pattern with a knife holes are cut for connection to the base.

- The temperature sensor, placed in a corrugated tube, is installed in a groove prepared in the floor. It is fixed in the center between two carbon rods.

- A thermostat is mounted on the wall.

- The operation of the underfloor heating system is checked within the first 15 minutes.

Important! Electrical installation must be carried out by a qualified electrician.

- The screed or special glue is poured over the carbon mats. Coating thickness (over two centimeters) ensures the uniformity of the finished floor. Only special mixtures for underfloor heating are used for the screed.

Switching on the heated floor is possible only after the solution has completely dried, which requires 28 days.

Water-based underfloor heating

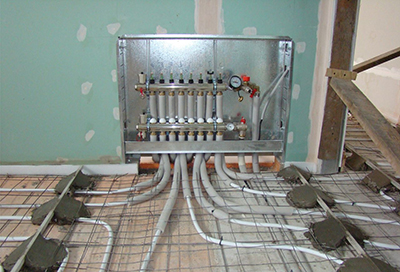

Water systems of "warm floors" are flexible pipes, in which the heat carrier (for example, water) is circulated. A screed is most often laid on top of such a system, but a “dry” installation option is also possible.

In old apartment buildings, this type of underfloor heating is rarely used, since Centralized heating systems are not designed for this.

However, in some new buildings there are opportunities to connect heated floors. More often, water systems are used in private residential buildings.

Peculiarities

Heat carrier with temperature no higher than 40-45 degrees enters the pipes of the structure from the boiler. Often, heating equipment provides stronger heating. In this connection, it is necessary to mix the cooled coolant with the one coming from the boiler. This is done with the help of a special thermostatic valve. The entire system functions with the help of a circulation pump.

Exists the only type of boilers, thanks to which the set temperature is obtained - this is gas condensing boilers. The coolant from such a boiler is sent directly to the underfloor heating pipes, and the mixing unit is not necessary.

Advantages

The following advantages of such floors are highlighted:

- uniform heating of the entire area of the room;

- indoor comfort;

- eco-friendliness (no electromagnetic radiation);

- economy (works from one boiler with a radiator system, the use of gas boilers is especially beneficial);

- absence of visible heating elements, which has a positive effect on the appearance of the rooms.

Flaws

Disadvantages of water heated floors:

- difficulty of installation in apartment buildings (mainly in old buildings);

- increased thickness of concrete screed (7–10 centimeters);

- labor intensity of installation;

- high financial costs for the system;

- possibility of leaks;

- difficulties of repair when using screed (to a lesser extent, this applies to the dry installation option).

Temperature distribution in the room

When heating rooms with any warm floor, the temperature is higher at the bottom of the room and lower at the ceiling. This is the temperature regime comfortable for a person, because the feet are warm and the head is cold.

Before installing water floors, the heat distribution system in different rooms and even their parts is planned and calculated.

In the bathroom or bedroom a higher temperature is comfortable, in the hallway it is not necessary. The coolant in the system circulates through long pipes and can cool down in the process.

In addition, if the floor area is large, there may be several loops of pipes, for this purpose they are arranged special mixing unitsThey allow automatic temperature maintenance.

Reference! If such a system is designed incorrectly, the heating of different parts of the floor will be uneven. To avoid mistakes, contact a specialized company.

Self-regulation

According to the laws of physics, heat is transferred from a hot object to a cold one. When the room temperature rises due to sunlight, the presence of people or household appliances, the heat supply from the water floor begins to decrease. And it, in turn, takes less heat from the boiler.

Thus, the house consumes exactly as much thermal energy as it needs, to compensate for energy losses. This is called the self-regulating effect of water heated floors.

Installation

Exists two main options installation of water floor:

- "Wet". A layer of waterproofing and insulation is laid on the base. Then a reinforced screed with heat carrier pipes is installed, after which the final coating is laid.

Photo 3. Installation of special aluminum plates is carried out with the dry type of installation of a water floor.

- "Dry". For this type of installation, special aluminum plates with grooves for pipes are used. A leveling layer, for example, made of plywood, is placed on top, and then the final coating is installed.

Useful video

The video shows the entire process of installing a rod floor system.

Conclusions: is it possible to heat a house with such a system?

Based on a number of reviews from experts and consumers, it can be concluded that it is possible to heat a residential building only with a "warm floor" system or its combinations with other heating methods. Such heating is characterized by uniform heating of different rooms, self-regulation of the system and saving of resources. The most suitable type of underfloor heating is selected for each room.