Warmth should be not only at home! Wood-burning stove for the garage: how to make the device with your own hands

Car enthusiasts spend a lot of time in the garage, especially one combined with a workshop, so it is important create comfortable conditions there, ensure fast and safe heating of the room.

Often, they install it for this purpose. gas or electric heaters.

But such devices have a number of disadvantages: high cost of equipment and resources, relatively low efficiency, low durability under conditions of temperature changes, high humidity, and exposure to aggressive external environments.

Therefore, one of the simplest solutions for heating a garage is to use a wood stove. Ideally, it should provide fast, uniform heating of air without filling the garage with smoke and wasting excess firewood.

Content

The nuances of insulation and wood stove schemes for garages

To maintain a comfortable home temperature inside a single garage it will be necessary to install a furnace capable of producing 2-2.5 kW thermal energy, for the operating temperature in 16-18 degreesin will be enough 1.8-2 kW.

Significantly increases the efficiency of heating wall insulationUsually the heat-insulating layer is placed on the outside, but this is expensive and technically impossible in the case where the garages are wall to wall.

Suitable for internal insulation self-extinguishing types of fiberboard and chipboard, but not plastic - it can release toxic gases when heated, which means that such material is incompatible with wood-burning stoves.

Brick garage wood burning stoves

Brick ovens are rarely installed in garages because of their bulky design. The devices take up a lot of space, and the large internal heat capacity increases the time lost in heating the oven to operating temperature. for 1-1.5 hours. However, in some cases, installing a brick oven is justified. Here are the most common ones:

- garage used as a workshop or semi-residential premises;

- the building has sufficient area and high ceilings;

- near there are no others garages, residential and household buildings;

- in the garage no excess moisture, which can damage the solution if the oven is not used for a long time.

For laying a wood stove it is used refractory and fireclay bricks, and is added to the binding solution fire-resistant clay.

Fuel chamber equipped below, usually at the level of the third row, if necessary, provide windows for the cleaning and blowing chambers. Particular attention should be paid to the chimney - its design should ensure effective removal of smoke and soot into the external environment.

Construction of a classic wood-burning brick stove with a cleanout window and without a blower ensures long burning of firewood and high heat output. Due to the relative simplicity of installation, the devices are often encountered in practice.

Sheet metal products

Metal wood stoves are popularly known as "potbelly stoves".

They represent single chamber design made of sheet steel, equipped with a chimney and an ash pan in which solid combustion products accumulate.

Often, a potbelly stove is supplemented with a cooking platform. Compared to brick ovens, metal the devices have such advantages:

- compactness and mobility;

- cheapness of source materials;

- high speed of room heating;

- ease of implementation of the chimney, removal of ash and cinders.

To make a potbelly stove yourself, it is enough have basic skills in operating a welding machine And with metalworking tools. Designs intended for installation in single-car garages are very simple.

In modern hypermarkets of construction and household goods you can find industrially made potbelly stoves. It is obvious that their price will be higher than homemade devices, but such products are reliable and durable.

Use of waste cylinders, device drawings

Empty gas cylinders can be used to make a very convenient wood-burning stove in just a few days. This design combines the advantages of brick ovens and potbelly stoves, allowing you to create a not too bulky, convenient device with long-lasting and intense heat output.

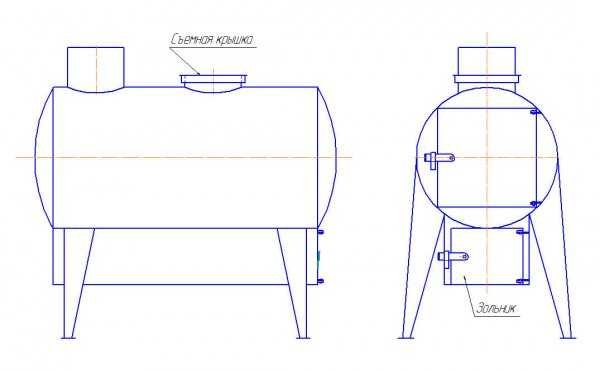

Photo 1. Drawing of a potbelly stove for a garage from a gas cylinder. Represents a horizontal type of construction.

When assembled correctly, such a stove provides thermal power more than 5 kW, which is enough to heat a large garage. One full download firewood guarantees 3-4 hours of stable combustion — this indicates the stove's economy. The structure can be easily equipped with a cooking area if desired. Among the types of wood-burning stoves considered, it is the cylinder stove that has the optimal ratio of material price, efficiency of use and ease of manufacture.

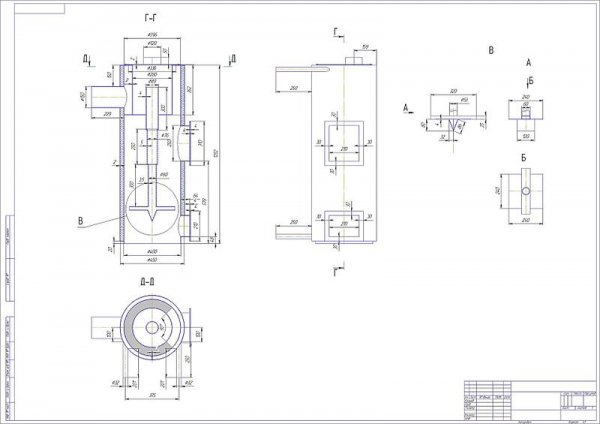

Photo 2. Drawing of a wood stove from a gas cylinder. The design is vertical, the dimensions of the device are indicated.

How to do it yourself: features of choosing a project

The main criteria characterizing a wood stove are its thermal power, expressed in kilowatts, and the average burning time of the wood in hours. The power is selected in accordance with the area of the heated room, usually based on the calculation 1 kW for every 10 square meters.

If the garage has high ceilings or an inspection pit, the power must be increased. The burning time depends on the type of wood used, the thickness and quantity of firewood, and the intensity of the flame. It should be at least 2 hours in temperature maintenance mode with an average fuel load.

It is important to consider the dimensions of the oven and its shape, the quantity and cost of materials required for assembly, the complexity and labor intensity of the work. It is best to create an oven using proven technology, having first familiarized yourself with the design drawings and photographs of the finished product.

Selecting materials and tools

The main raw material for the manufacture of a cylinder furnace is waste gas cylinders. Instead of a vertical cylinder, you can use a thin-walled (about 5 mm) steel pipe with a diameter of 300 mm.

In addition, you will need reinforcement bars or small diameter steel pipes, sheet metal of thickness 3-5 mm, fasteners, and hooks and latches for fixing the lids on the firebox and ash pan windows.

Tools, necessary for making a stove, are in almost every garage, These include:

- hacksaw for metal;

- file and sandpaper;

- grinder with abrasive cutting discs;

- drill with metal drill bits;

- welding machine with electrodes;

- screw clamps.

Before you start working, It is necessary to take measurements of the room and make sure that installing a fairly large wood stove in it will not cause any inconvenience. Then you need to prepare the cylinders.

Attention! Cutting a gas cylinder can be dangerous to life and health if you do not follow the instructions safety regulations.

First of all, you should open the valve completely and release the remaining gas, controlling its output with a soap solution. Then, using a hacksaw, carefully cut off the valve at the very base, constantly adding water to the cutting site. The cylinder freed from the valve is filled to the top with water, shaken, the liquid is drained, and only then do they start cutting the walls with a grinder.

We construct a wood-burning stove

Further steps to make a wood stove from cylinders can be reduced to a simple algorithm:

- In place of the first cylinder valve cut out a rectangular window for the woodshed, in its wall they make long thin slits for the grate, and opposite them - a window for fastening the secondary chamber.

- From the second cylinder make a secondary camera, cutting off its bottom in a wedge shape. In place of the valve, a hole is cut for the chimney pipe.

- From sheet metal cut out the patterns for the ash pan and the receiving window, partitions of the secondary chamber, as well as 10-15 long strips of width about 50 mm - they will serve as radiator fins.

- Receiving window and ash pan welded onto the first cylinder, supports made of pipes or reinforcement are welded to the ash pan and the lower part of the woodshed.

- Partitions are welded into the secondary chamber, and an adapter for the chimney pipe is installed on it.

- The secondary chamber is welded to the woodshed Above the corresponding window, the outer surfaces are welded with radiator fins, and the doors of the receiving window and ash pan are installed.

- The structure is covered with heat-resistant paint to prevent oxidation and destruction of metal.

- The stove is installed in the garage and equipped with a full-fledged chimney, emitting combustion products into the environment.

The end result is a bit strange looking, but a very effective heating agent.

The main difficulty you may encounter when assembling a wood stove is an uneven and, as a result, unreliable weld. The cause of the problem is insufficiently precise cutting of parts or poor processing of mating surfaces. Therefore, it is important to pay attention to preliminary marking, work with the grinder slowly and carefully, and before welding, give the edges the desired shape and clean them with sandpaper.

Photo 3. A finished wood-burning stove made from a gas cylinder, which can be used in a garage.

Useful video

Watch the video, which tells you how to make a stove for your garage from a gas cylinder with your own hands.

Conclusion

A properly assembled wood stove will become a reliable, long-lasting source of heat in the garageIts design ensures product safety, stable operation in difficult conditions and unpretentiousness to the type of fuel.

Comments