A do-it-yourself metal sauna stove will provide high efficiency and fast heating

Heating stoves for baths made of metal have long been widely used due to their special qualities.

Such devices are practically in no way inferior to traditional brick devices, even are characterized by higher efficiency And heating rate.

Their compactness, ease of use, and low cost become undeniable advantages for owners of suburban areas.

Many metalworking shops offer services for the production of metal furnaces according to the customer's individual project. This makes it possible to obtain a device designed to operate taking into account specific factors and possessing a set of required functions.

It is not difficult to make a wood-burning metal stove with your own hands, especially if you have experience with welding.

Content

Design features, drawings

There are different types of heating devices of this kind, They are united by common design elements:

- Frame — most often made from sheet steel, in which it is convenient to cut holes for the chimney and firebox doors, ash pan.

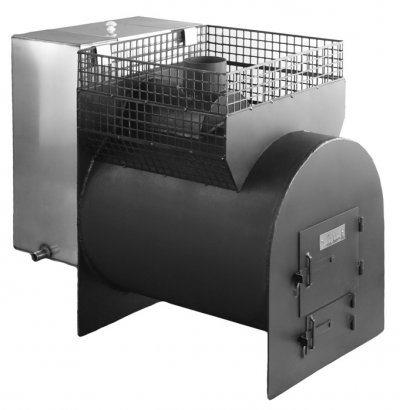

Photo 1. Drawing of a metal stove for a bathhouse (front view, side view) and an image of the device in its finished form.

- Firebox — usually a separate box is made of steel of sufficient thickness (not less than 5 mm), consisting of the firebox itself and a sliding ash pan welded to the bottom. It is separated from the firebox by a steel grate with large cells. In addition to collecting soot, the ash pan performs the function of supplying air to the firebox, i.e. it creates traction.

- Kamenka — a metal basket for stones, most often located directly above the firebox for better heating. The heater comes in two types: open, providing convenient steam generation, or closed, located inside the stove body.

- Water tank — can be located either next to the heater or above it. Usually the water tank is supplied with a special tap that supplies water to the hot stones, this ensures the formation of steam.

- Chimney - removes combustion products, smoke and hot air to the street, also creates draft.

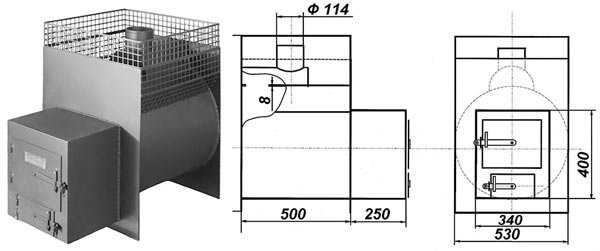

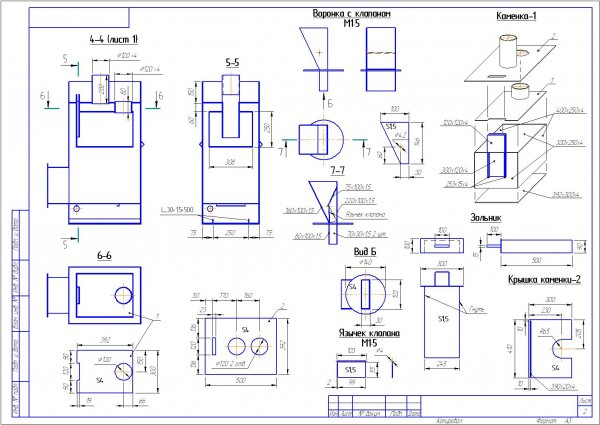

Photo 2. Drawing of a metal sauna stove: every detail of the device is worked out, dimensions are indicated.

Metal stoves tend to heat up a lot during operation, intense heat can cause discomfort to those in the steam room, and the hot surface can cause burns. Therefore, this type of device is usually are faced with stone or brick — in addition to protection from heat, the screen, along with the heater, acts as a heat accumulator. After the stove goes out, the brick screen will continue to heat the air for a long time, drying the steam room after its use.

There is another common way to reduce excessive heat from a stove: the firebox is lined from the inside fireclay (fire-resistant) brick. This method is called lining and has its drawbacks. Overheated air, getting into the chimney, may cause a fire. Therefore, if the firebox is being lined, it is recommended to install a heater above it to absorb some of the heat.

Scheme and dimensions of a simple metal stove for a bathhouse

The most common compact oven has an elementary design and is quickly welded from sheet steel. The body is rectangular, the dimensions are 55 cm x 30 cm, height about a meter. Inside the body there is an ash pan of height 15 cm, combustion chamber height 30 cm. An open grid for stones is installed above the firebox. The chimney pipe rises directly from the firebox to the roof, passes through the heater, giving it a significant portion of the heat.

Reference. To make an even simpler model, you will need old propane tank, which is used as the body of the stove. Holes for the firebox doors and ash pan are cut in the end. A round opening is made in the side wall for connecting the chimney. The cylinder itself is installed horizontally on legs.

Vertical iron stove

The most compact option is a tall vertical case in which all parts are located one above the other.

The dimensions of such a device can vary in accordance with the area of the steam room. On average, for a small room, the optimal dimensions will be 0.5m x 0.5m x 1.3m.

A vertical boiler can contain two or three compartments. It depends on whether a water tank will be installed. The lower chamber contains the firebox and ash pan (the size of the firebox determines the power of the stove and the burnout time of one batch of firewood).

An internal heater is installed above the firebox, with a height of about 45 cm, a door is cut in the body for laying stones.

A water tank is placed directly above the heater, the size of which depends on the needs of the users (the height of the entire stove is selected accordingly).

A chimney is installed above the tank, which is connected directly to the outlet from the firebox. An air gap is left between the walls of the body and the internal chambers. not less than 3-5 cm to protect external walls from overheating.

Horizontal sauna stove with remote firebox

This device takes up more space, but provides the opportunity to place the main part of the stove in the next room or on the street. This option allows for more convenient operations on loading firewood and cleaning the stove. If the stove is brought out into the dressing room, it also heats the second room, which is an additional advantage. In the steam room itself, there is only a firebox, and a heater located above it.

When installing such a device special attention requires attention fire safetyThe partition through which the firebox will pass is carefully insulated.

Best brick up the firebox, this will eliminate heat loss from the steam room. In the dressing room, the walls and floor in the area where the stove is located are covered with fire-resistant material.

The average dimensions of such a stove are 0.5 m wide, 1 m long, the height depends on the size of the heater located above the firebox.

Making a metal stove with your own hands

When choosing a drawing for making a stove with your own hands a number of factors are taken into account:

- area of the premises — the dimensions of the device depend on it;

- availability of desired functions — heating air, water;

- presence of a heater open or closed type;

- heat capacityь — protective shielding.

The location of the device in the room also plays a significant role. If you need a compact stove for a small steam room, a corner location. In this case, it is better to choose a model with a remote firebox or a vertical one. When located in the center of the steam room A large-sized stove can be horizontal and massive for high-quality heating of the room.

Materials

When making a stove yourself, preference is given sheet steelIt is easy to cut and bend, and the material itself is resistant to burning.

For a homemade stove to last, a fairly thick layer of steel is required, but the layer width is too large (for example, 1 cm) may lead to prolonged heating of the device and a decrease in its efficiency.

Therefore, the optimal choice would be steel with a thickness of 5-7 mm for firebox And 3-4 mm for the body.

Other details - doors, hinges for them, valves, tap for the water tank, grates for the ash pan and the heater recommended to buy in specialized construction stores. The chimney is made from pieces of pipe of a suitable diameter (not less than 10 cm), legs - from metal scraps of sufficient thickness to support the weight of the stove, as well as the mesh with stones. To fill the heater Round river boulders of suitable size will do.

Tools

To complete all stages of the work, you will need the following tools:

- welding machine;

- grinder with a cutting disc for iron;

- container for mixing the solution;

- stove hammer-pick;

- trowel;

- rule.

To ensure that the work is carried out safely, it is necessary to purchase protective equipment: a special mask and gloves. You will need various measuring instruments: tape measure, building level.

Construction stages. How to weld a structure correctly?

First of all, a place is prepared for the stove, the foundation is being laid. Most metal devices are compact, so they do not require concrete pouring; it is enough to lay out a foundation of two rows of bricks. If it is decided to lay out a heavy brick screen, it is more advisable to take care of a full-fledged foundation:

- The floor in the place where the stove is installed is dismantled and a pit is dug half a meter deep.

- It is poured onto the bottom drainage pad: a layer of wet sand, a second layer of crushed stone or special granulated expanded clay.

- It is placed on the drainage wooden formwork, filled with concrete mixture.

- After the foundation has dried, it is laid on it two-layer waterproofing (roofing felt).

After preparing the foundation, thermal insulation of the future place for the device is provided. The walls and ceiling are covered with fire-resistant material, the device itself is installed so that there is a gap to the walls not less than 30 cm.

Then they begin welding the structural parts:

- According to the drawing, using a grinder, pieces of sheet steel are cut for the body and internal chambers.

- The sides are welded walls, bottom of the body. Openings for the firebox and ash pan are cut in the front part. Inside, they are welded to the walls of the body. metal corners for fastening compartments.

- Welded and installed firebox and ash pan with a lattice separating them.

- Welding and subsequent placement of the internal heater and water tank (if included in the project) is carried out.

- It is welded chimney pipe And body legs.

After installing the stove, a brick screen is laid out with an indentation calculated in 3-5 cm from the walls of the device. The width of the masonry is usually taken as half a brick, small windows are left in the lower part for air circulation.

Possible installation difficulties

When working independently on the manufacture of the device The following errors occur:

- mismatch between the size of the device and the steam room — leads either to rapid overheating of the air or to the inability to create a comfortable temperature;

- insufficiently thorough insulation of the chimney — due to constant contact with hot air, the chimney most often becomes the cause of fire hazard situations;

- incorrect placement of the oven screen, too close to the walls of the housing - this leads to overheating of the steel, reducing the service life.

Attention! In order to avoid basic mistakes, you should create a template before starting work. precise drawing apparatus and consult with an experienced craftsman.

Photos of finished hardware devices

Photo 3. A sauna stove made by hand. It is made according to a vertical scheme and is additionally equipped with a water tank.

Photo 4. A sauna stove made of metal with a remote firebox. It also has a water heating tank.

Photo 5. Horizontal metal stove for a bathhouse. It is located on a brick pedestal, which prevents the surrounding surfaces from catching fire.

Useful video

Watch the video, which demonstrates all stages of the process of making an iron stove for a bathhouse.

Decorative finishing

If a decision has been made to abandon the brick screen, the metal stove is often lined with other materials to give it a more aesthetic appearance. Facing natural stone — quite an expensive option. Classic type of cladding — clay tiles. The composition of the material helps such tiles to withstand temperature changes and humidity in the steam room, and the appearance will give the bathhouse a unique design and please visitors with coziness.

Ceramic tiles are different affordability of price And a wide variety of colors, but has a significant drawback - general fragility and weak adhesion. The best choice would be clinker tiles.

It is highly wear-resistant and can withstand exposure to hot air.

Wide range of colors to choose from will allow you to choose the right option for every taste, and affordable price will not ruin the family budget.

Now in stores and in the article a stove with a straight chimney is shown. In order to increase the efficiency, I made the outlet a knee, my exhaust pipe does not go straight from the stove, but comes out from behind the stove and through the knee forward, only then goes straight up. Thus, the heat transfer surface for heating the stones has increased and you heat less of the street.