Safety first! How to easily and without fuss build a protective screen for a sauna stove?

One of the most important properties A good steam room requires high-quality heating of the room and maintaining a high temperature for a long time.

It is provided by the operation of a bath stove, which can be made from various materials – brick, stainless steel, cast iron.

If brick products allow you to gently heat the air and do not create additional problems, then metal stoves require a special screen.

Content

What to cover the stove in the bathhouse with? Options for frontal protective screens

Metal furnaces are the most practical and convenient for installation in small spaces, they effectively cope with heating air and water.

But metal has significant drawback - with constant heating its surface becomes hot and can reach a temperature 400 degrees.

This creates uncomfortable conditions in the steam room. The hot metal often becomes cause severe burnsOften, most of the heat is absorbed by the walls, i.e. it goes to heating the street.

To solve all these problems, eliminate the risk of a fire hazard, provide better quality soft air heating, metal sauna stoves screen.

The most suitable material for this - a brick with high heat capacity, capable of maintaining high air temperature for several hours after the stove is no longer fired.

Screens are successfully used to protect the wooden walls of the steam room from overheating and maintain the desired temperature. made of stainless steel. They are distinguished by their reflective properties and direct heat back into the bathhouse. They are also common combined options furnace screen structures.

Metal screen

The stainless steel screen performs two functions: reflection of heat flow and infrared radiation from the furnace, prevention of fire hazards. This requires that the design met the following criteria:

- It is better to choose a steel sheet polished, such material has significantly more advantageous reflective characteristics.

- There must be a distance between the wall and the screen; if there is no insulation on the wall, the distance to it is not less than 50 cm, if the walls are covered with non-combustible material it is enough 30 cm.

- Leave a space of at least between the walls of the oven and the screen 3-5 cm.

- The sheet size should overlap width stoves, the height is often chosen depending on the location of the chimney, which, in the absence of insulation, also emits a large amount of heat. A common option is when the screen covers the wall behind the stove almost to the ceiling - for safety reasons to the ceiling better to leave about half a meter.

The metal screen will not only protect the steam room from overheating, but will also improve the speed and quality of air heating in the room. Due to the simplicity of its design, easy to install yourself.

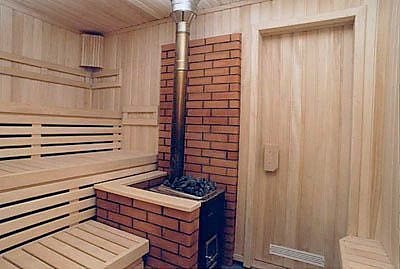

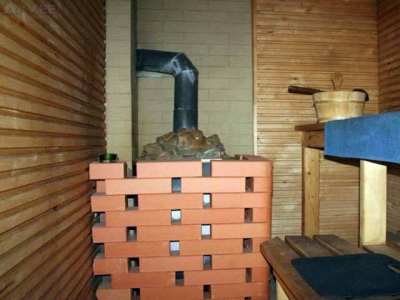

Brickwork around an iron firebox

Since the walls of metal stoves get very hot during operation, a protective screen made of brick will be the best option. This material allows create an atmosphere in the steam room softer and reliable will protect surrounding walls from overheating and the risk of fire hazards. Such a design has the following characteristics:

- masonry width half or a quarter of a brick;

- distance from the walls of the stove to the brick surface not less than 5 cm;

- the screen size is larger than the device itself and reliably protects the walls from heat waves; most often a box is laid out, leaving only the front open the side where the firebox door is located.

Attention! The downside of this option would be long warm-up period steam room, but this is fully compensated by the milder heat, which is beneficial for health.

The ability of brick to accumulate heat and then gradually release it will make your stay in the bathhouse not only more pleasant and longer, but also will increase the service life of the steam room itself. Residual heat helps dry the walls and protect them from dampness.

Brick fence for a cast iron sauna stove

The properties of cast iron allow accumulate heat without intense radiation into the surrounding space, so such a stove does not require protection from excessively intense heat.

But a high degree fragility This metal makes it vulnerable to sudden temperature changes. If you carelessly splash water on a hot cast iron stove, the consequences will most likely be irreversible.

Therefore, it is recommended to install a protective screen first of all, for the durability of the heating device itself.

The brick cladding of this type of product is several times will increase the duration of its heat transferAfter the screened cast iron stove heats the steam room to the desired temperature, there is no need to maintain the fire in the firebox; for the next few hours, the soft heat will come from the heated cast iron and brick.

Dimensions screen depend on the dimensions of the heating mechanism, but when installing it, you must leave it at least two sides of the oven openOtherwise, the cast iron will overheat in the brick box, which will create a risk of condensation and reduce the service life of the material.

Building a stove with a heat-resistant shield with your own hands

If you decide to equip the steam room with a heating device yourself, it will be suitable simple scheme metal furnace with protective brick screens.

For a medium sized steam room up to 20 sq. m a welded corner bath stove would be a good choice made of 5mm thick sheet steel. The design is simple. The firebox is located at the bottom, and above it is the internal heater compartment. A branch pipe is installed on top for connection chimneyIf necessary, a heater is placed next to the heater. water tank.

Selecting a project

The laying of a standard screen for a bath stove made of metal is carried out half a brick wide. The masonry option is also widespread. a quarter of a brick, it is lighter in weight, but has lower heat capacity and strength.

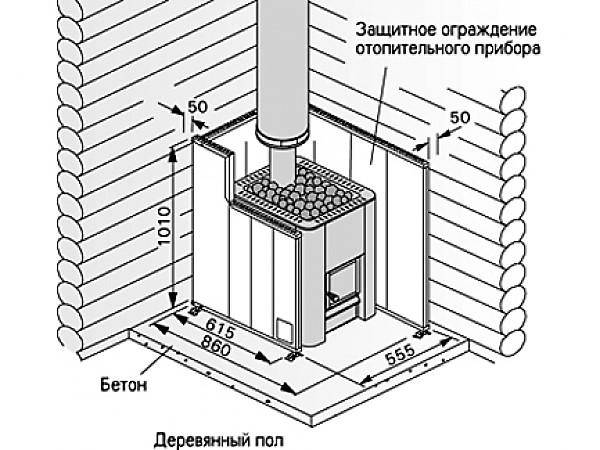

Photo 1. Installation diagram of a protective screen around a sauna stove. Dimensions are in millimeters.

When choosing the type of design, consider:

- load-bearing capacity of the floor covering — brickwork has significant weight and, in the absence of a reliable foundation, requires the installation of a foundation;

- temperature, to which the device heats up — at high rates it makes sense to choose brickwork, it will provide better protection from intense heat and will only increase the period of heat transfer;

- desired heating speed steam rooms - to increase it it is better to leave one wall open;

- open or closed top — if the masonry is solid, then for ease of servicing the stove, the brick box is left without a top.

For a welded steel structure, a solid half-brick masonry with an open top and gaps left at the bottom is best.

Materials

It is best suited for laying solid brick. Even though it takes longer to heat up, it high heat capacity allows you to dry the steam room in the best possible way after use.

Depending on the size of the heating device, the thickness of the masonry, the number of gaps left, the calculated The number of bricks required will vary. For correct calculations, it is recommended to draw up a diagram before starting work.

Ready masonry mortar can be purchased in hardware stores or made independently using fatty clay and fine-grained sand. Soaked in water, the clay is rubbed through a sieve and knead, adding sandTo increase the strength of the solution, it is recommended to add to it up to 10% cement.

Important! For laying You cannot use a specialized heat-resistant solution. In order for such a composition to set properly, it requires high temperatures, which are not provided by the protective lining of the furnace. Therefore, such a special solution will crack quickly, gaps and cracks will begin to appear.

Tools

To independently make a heating structure from steel and surround it with brick cladding, you will need corresponding set of tools:

- welding machine;

- protective mask and gloves;

- building level, plumb line, cord;

- grinder with cutting disc;

- hammer;

- container for solution;

- trowel;

- rule.

The grinder will be useful both for cutting pieces of sheet steel to the required size and for dividing bricks. Therefore, it is necessary to take care of it in advance. discs for metal and stone.

Construction stages

Construction begins with the device foundation or a durable non-combustible base:

- If the floor of the steam room is not able to withstand the weight of the stove, heater, cladding, then it is dismantled and a pit is dug for the foundation. In the case of installing a brick foundation on the foundation of the steam room, a thermal insulation layerCeramic tiles and steel sheets are also suitable for the base.

- It is cut out of metal and welded device body.

- It is welded smaller steel box, it is installed inside as a heater.

- Welding of an oblong box is in progress chimney.

- Need to do some welding additional tank for heating water, and the dimensions are calculated so that the heater and water tank are located next to each other inside the body.

- It is cut out opening for the heater and for the firebox door, legs are welded to the bottom.

- Execution begins masonry at a distance of 5-7 mm from the walls of the oven to form a channel through which hot air will rise.

- In the lower layers the clutches are left small gaps-windows, Depending on the chosen project, they are also made in the walls.

- The masonry is in progress with offset, each seam is covered with a brick from the next row.

- Necessarily the evenness is checked masonry using a level and plumb lines.

- In accordance with the project, it is installed top or net is installed.

Gaps for air flow to the furnace ensure the creation of air exchange, they will allow you to maintain the high efficiency of the metal heating device, while not depriving the bricks of the ability to accumulate thermal energy. For ease of use, gaps often equipped with doors, in the open state the steam room heats up faster, in the closed state the main heat accumulates in the screen masonry.

Possible complications

When building on your own, it is easy to make mistakes mistakes:

- the lack of space between the brick and the walls of the stove leads to disruption of air exchange, overheating and cracking masonry;

- insufficient distance from walls the steam room has a negative impact on both the strength of the masonry and fire safety;

- usage unsuitable solution leads to the appearance of cracks, crumbling of the solution, and the formation of unnecessary gaps.

The laying of the screen for the stove is different quite a simple technology, so with careful attention even a novice master can handle it.

Useful video

Watch the video to see how to install fire-resistant protective panels on the walls around the stove.

Benefits of Building a Screen

If the brick cladding work is carried out correctly, the result is a structure that increasing positive properties using the steam room:

- A screen with vents does not interfere with the speed of heating the room, and the ability of bricks to accumulate heat will ensure long-term pleasant and healthy heat.

- Brick cladding will help improve the aesthetic appearance stoves, will allow you to decorate the interior of a sauna or bathhouse.

- Building a screen will protect against burns due to negligence.

- Drying the steam room after use will have a positive effect on its properties and durability.

- Installing the screen will reduce the risk of fire, will prevent both excessive heat loss and overheating of the air in the room.

The brick fence will be effective for both the heating device installed in the middle of the steam room, and at corner arrangement structures near walls. Building such protection with your own hands will not require large financial and time expenditures and will significantly improve the overall functionality of the bathhouse.

Comments