A long-burning greenhouse stove will allow you to grow flowers and pineapples in January

A greenhouse is a salvation in unfavorable climatic conditions in some areas It is impossible to obtain a quality harvest without its installation.

Equipping the greenhouse with an additional heating stove expands its capabilities — plants are no longer afraid of long periods of low temperatures, when a regular greenhouse inevitably cools down.

The use of a greenhouse becomes possible even in winter, that is all year roundThe greenhouse oven also allows you to grow more exotic heat-loving varieties vegetables and fruits.

Wood burning stoves for heating greenhouses

The choice of heating devices for the greenhouse is also diverse, as for home. Most often, factory models are used, which are purchased in stores, but it is possible to make such a device yourself.

The ovens differ as by fuel type - wood, gas or electric, as well as by material of manufacture - metal or brick.

The most common choice for self-construction is solid fuel apparatus, which is heated with firewood, pallets of chips, husks, and dry pieces of peat.

A regular greenhouse stove

A device of this type can be made of metal or brick.

Metallic the stove is quite easy to build, it is recommended to weld it from an old barrel or gas cylinder, size 1.5 m x 0.5 m. A distinctive negative feature will be the inability to retain heat, therefore, as soon as the fuel in the stove burns out completely, the greenhouse begins to cool down.

It matters uneven heating — the stove has a high heat output due to the metal body, so the air in the immediate vicinity of it overheats greatly, which negatively affects the soil and plants.

Construction of the furnace made of brick will allow you to get longer, gradual heating of the room, as well as long-term heat transfer after the firewood has already burned out. The construction of an elongated horizontal smoke channel will significantly increase these indicators.

The dimensions of such a device may vary depending on the area of the room, smoke channel usually posted along the entire length of the greenhouse — located in the center, it promotes high-quality, uniform heating of the air.

Important! The primary purpose of a greenhouse oven is soil warming, therefore the smoke channel and the device itself are located as close to the ground as possible.

Long burning device diagram

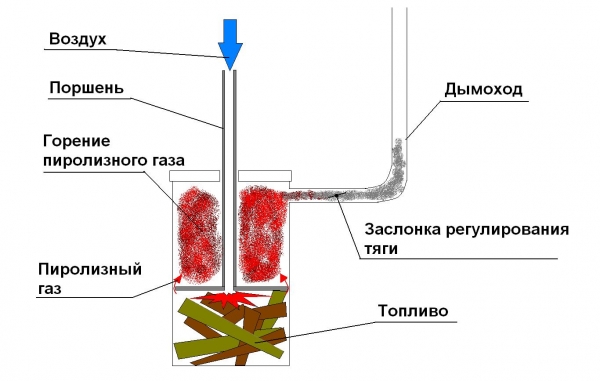

To increase the efficiency of the furnace, it is often equipped double combustion chamber - this allows extend the effect of one load of firewood for 12-18 hoursThis is achieved through the process pyrolysis — due to the controlled flow of air into the firebox, the wood does not burn in an open flame, but smolders very slowly, releasing a large amount of smoke and hot gases. Second camera The furnace serves for the final combustion of the released combustion products.

Photo 1. A diagram demonstrating the design of any long-burning furnace with a limited oxygen supply.

With this method of heating you have to add fuel much less often, and pyrolysis combustion leaves almost no waste, so you won't have to clean the firebox from ash oftenSaving fuel and time required for maintenance makes this option the most popular. Dimensions can be quite small - 1.5m x 1m, more efficient heating of the air will be ensured by the installation horizontal smoke channel.

Making a stove with your own hands

The choice of the design of the future device is mainly depends on the existing conditions and desired functions. If heating is required small greenhouse, the device will only work periodically, for example, to ensure earlier sowing of seeds in the spring, a small potbelly stove of simple design will do.

With constant use of heating, for heating large areas, significant volume of fuel consumption, the most suitable option will be economical designs based on pyrolysis combustion. Compactness and ease of installation are important - a small device made of steel easier to install and commission, brick Due to its massiveness, the structure will require the laying of a foundation, and the construction work will be more labor-intensive and time-consuming.

Preparation of materials, tools, place

The following materials are suitable for building a stove:

- metal barrel of suitable diameter;

- trimmings metal pipes;

- steel sheets of sufficient thickness;

- old gas cylinder.

To make a long-burning stove body, a barrel or cylinder would be a suitable option. with a capacity of 200 l for the body and cutting of pipes for chimney equipment, pieces of steel, fittings.

In addition to materials, you need to prepare special tools:

- marker for marking;

- Bulgarian with steel cutting discs;

- welding machine;

- protective gloves and mask.

Then a place is selected and prepared - it would be best to install a stove in the middle of the greenhouse. Necessarily the foundation is being builtAlthough a metal device does not have as much mass as a brick one, a reliable foundation is required for it - a suitable paving slabs, bricksThe materials are laid out in even rows on a compacted, leveled area of land.

Assembly order

The work starts with the body:

- From a cylinder the top part is cut off, V lower part an opening is cut for loading fuel, from the side - opening for chimney equipment.

- The resulting the metal circle is being turnedso that it can pass freely into the barrel.

- It is cut out in a circle blower hole, the circle itself gets heavier reinforcement or pieces of metal.

- It is welded to the lid pipe cutting with a damper that functions as a blower.

- It is welded chimney, door, made from a bent sheet of steel or the wall of a barrel.

- It is being attached metal fittings or legs.

Operating principle such a homemade device - to ensure smoldering of firewood with a limited supply of oxygen. Under its own weight, the lid gradually falls, simultaneously showing the level of combustion of the fuel.

Possible complications

When assembling, it is advisable to avoid the following: errors:

- Installing directly on the base causes overheating, burnout of the bottom; there must be an outflow of hot air from the bottom, so the device is placed on sturdy legs.

- Installation of the stove near unprepared walls may be unsafe because steel devices get very hot, so there is a high risk of fire when placed near objects.

- Excessively large blower diameter leads to excess oxygen, causing the wood to catch fire instead of smoldering; corrected with well-adjustable valve.

The device has quite simple design, so if you approach the work carefully, you will be able to avoid most of the mistakes.

Useful video

A video demonstrating how to make a stove from a barrel to heat a greenhouse and how long the fuel lasts for it.

Safe Operation Rules

The main danger when using a stove in a greenhouse is high risk of fireTo prevent fire, it is better to keep a fire extinguisher or a container with sand in the greenhouse.

Attention! It is not recommended to leave it near a working unit. small children unattended - the hot walls of the oven can cause serious burns.

Following simple rules will protect you from fire:

- remote installation not less than 0.6-0.8 m from the walls;

- security chimney thermal insulation;

- do not engage work on kindling the stove and adding firewood if you feel unwell, are very tired, or intoxicated;

- do not store fuel in the immediate vicinity proximity to the firebox.

Comments

When constructing such a stove, you must first take into account the heating area and the lowest night temperatures in your area.

Only stoves with a burning time of at least 10 hours are suitable for heating greenhouses. When constructing a homemade stove, calculate the volume of the combustion chamber for exactly this burning time. Otherwise, sleepless nights during frosts are guaranteed.