Reliable stove: what kind of brick is needed for its laying

A stove is a structure that in the modern world competes equally with heating devices.

It is used not only for heating, but also for cooking. Heating technology has a beneficial effect on the human body and does not dry the air.

Since ancient times, it has been customary to build a stove with your own hands, putting positive energy into each brick.

Content

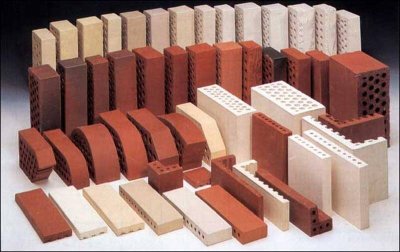

What brick to choose for laying a stove

Brick - the main material for building a stove, and if you are taking on the job yourself, it is very important not to rush, but to get a complete picture of the types of bricks in order to find the best quality products and build a structure that will serve you for many years.

Photo 1. Classic stove made of brick. The better the quality of the material used, the longer the device will last.

Wrong choice of material may cause a fire in the house. It is necessary to choose only the highest class brick, which plays a huge role, especially when building a combustion chamber. The material must be marked, must not crumble, and when lightly struck, produce a ringing sound.

Clay bricks are resistant to high temperatures. If the material is of high quality, it should not have any voids inside, there should be no cracks, chips or unevenness on it. All these parameters are very important when choosing, because when building a stove in the house, you are worried about your safety and the safety of your family.

Types and brands of bricks

The material for building stoves is of different quality. For the base you can use sand-lime bricks, but for the camera they should be ceramic, because this material will retain high temperatures inside. Dense or solid brick should be used for the inner walls of the stove, and more accurate facing tiles are better for finishing work.

Fireclay brick used for construction combustion chambers. It is fireproof and can withstand high temperatures. The materials for building the stove differ in size from ordinary building blocks. Bricks made of fire clay or graphite powder, but it is worth remembering that you cannot build the entire stove out of them, because in this case it will heat up a lot and quickly give off heat.

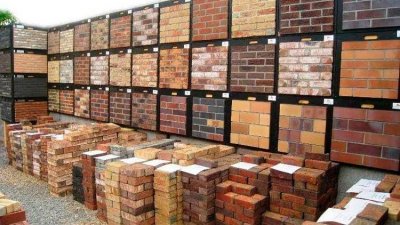

Photo 2. Fireclay brick blocks. Sand-colored material, fireproof, withstands heavy loads.

Functionality, what to use for different parts of the stove structure

Bricks are intended for interior finishing of the stove, for cladding and additional decoration. During construction cameras And internal masonry recommend using clay ones. They are hardened, withstand high temperatures, and retain heat longer in winter.

Brick grades are indicated by a combination of the letter M and a number that indicates the level of permissible load on the material. For laying any of the sections of the furnace, a grade of at least M150For more massive buildings, brands are used. M200 or M250.

For construction, it is very important to follow all the recommendations of specialists. As for the facing material, it should be light and neat, often its front part is covered with enamel or special ceramic glaze. Facing tiles retains heat, but it is not capable of heating up much by itself. When choosing a material for cladding, it is important that it is smooth and without defects, the edges of the tile should be carefully sanded, without chips and scratches.

There are several types of material for the construction of the interior:

- To the first grade can be attributed to a fired brick with a good structure and a transparent film on top. It is dense, with clear edges and without damage.

- Second grade more porous structure, but at the same time, it retains heat well. The difference with the first grade is in the different degree of firing, the color of the second grade is not so rich and bright.

- Third grade the most unstable to temperature changes, it is often used for laying the foundation of the stove. It is dense, but not porous.

Before purchasing any of the varieties, it is worth make sure of its quality - it must have clear edges, no damage, marked and well packed. All corners of the material are securely protected. Each package must contain operating instructions, and it describes the type of material, where it can be used and at what temperatures.

The facing should also be approached seriously. High-quality tiles will serve for a very long time, there should be no cracks or chips on them when purchased, and the set should include instructions for use and proper operation.

Types of material, which is the best

Fireclay brick more expensive than ceramic, but it maximally resistant to high temperatures. The material is durable, but heavy, and completely non-porous. It is often used in industry, it tolerates temperature changes well and is frost-resistant. An important point in preparing for construction is difficulty of cutting fireclay, which is why it is rarely bought.

Fireclay is often used in cladding works, because of its sandy color it fits very well into any interior design. The material comes in different shapes, which is convenient for construction. absolutely harmless to health, a little more expensive than the usual ceramic one, but better and more reliable.

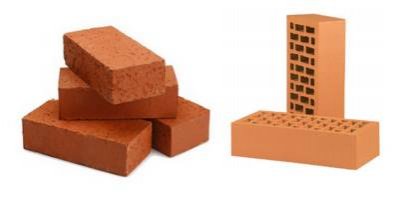

Ceramic — the most popular, lightweight, durable, reliable type of material. Due to its affordable price, it is often used in the construction of all kinds of structures. Waterproof, durable, long lasting. It consists of clay with various additives that create porosity and thus allow heat retention. It should have clear edges, without chips. The highest quality material will serve perfectly, and if used correctly, it will retain its original appearance for a long time.

Photo 3. A pile of ceramic bricks of two types: solid and hollow. This material is the most popular in the construction of various brick structures.

Sand-lime brick made of quartz sand with impurities. Standard sizes, but more expensive, because its production takes a lot of time and money. Russia is considered one of the leading countries in the production of this building material. Refers to top category materials for finishing and decoration, differs reduced temperature resistanceIt is impregnated with special agents, which allows the brick to breathe, thus it transmits heat well and does not heat up from the outside.

Material design

Full-bodied brick is used more for the foundation, because it is frost-resistant and fireproof. According to its characteristics very durable, it is difficult to split when struck. It is characterized by thermal conductivity and high moisture resistance. It is also used in the construction stoves, fireplaces or chimneys.

It is important to take into account that it is not recommended to use it for building walls, and if this happens, then the surface must be properly and reliably insulated for further work.

Hollow used for interior work. Walls, stoves, fireplaces It is built from it. Due to the voids inside, it has good thermal conductivity and retains heat for a long time. Porous or hollow is obtained by adding various peat impurities to clay, as well as coal. The cost of such material is low, so it is used most often in modern buildings.

It is important to remember that the solution used to build a hollow brick oven must be very thick - this will ensure the solidity of the structure, reliability and durability.

But when loading and unloading this type of brick, you need to be careful with it. Material very fragile and when falling easily damaged.

Criteria for choosing bricks for construction

If you saw on a brick some kind of film or coating - this means that it is not tempered correctly and, as a result, will not withstand high temperatures. It is very important to check the material by sound - a light blow on the brick should be accompanied by a metallic ringing. This will confirm the quality and correct production technology. Such selection criteria will help to find a material that will serve reliably for many years.

Important! Decide on the type of material, its quality, and markings. Externally, it should be correct shape, no chips or damageThe packaging must be tight and secure.

Bricks for different types of stoves

Russian stove have long been built by hand, now such devices are very popular due to their cost-effectiveness. The simple design allows you to build the device on an additional foundation, which gives the stove special fire resistance and durability. The heating device is famous for the fact that it can create the optimal temperature for both cooking and heating the room. Its secret is that due to the design features, soot and carbon do not get inside.

To build you will need premium grade brick. Use solid ceramics for interior work, hollow ceramics for decoration. If the design requires a special color, you can use lighter-toned silicate brick for finishing.

Mini oven. In its characteristics it is the same as a large Russian stove. With a small difference - a mini-stove can be easily folded and placed in the car. Such ease of transportation has won the hearts of consumers. The device can be taken on a picnic, placed on the veranda or even on the balcony of the apartment.

The mini-oven is heated both with regular coals and simply with electricity. Unfortunately, the device is quite expensive, as it is made in Europe and has no analogues in Russia. There are many designs that can also be classified as a mini-version of the stove.

Fireplace. For a fireplace, which is now very common in many houses and apartments, it is better to use refractory fireclayIt holds high temperatures well and has excellent heat transfer. The material is almost impossible to damage, it will serve for a very long time if used correctly.

Photo 4. A fireplace made of two types of brick: fireclay and ceramic. The first is used to line the interior of the device, the second is used to line the exterior.

When heated, fireclay bricks there is no smell or harmful fumes, so it is safe to leave it where there are children. Fireclay will easily fit into the interior of your apartment or house, as it has a neutral sand color.

Dutch oven. This monolithic structure is larger similar to a blind furnace. They use it for its construction. best quality brick. Such a stove can heat a large room, but unlike a Russian stove, you cannot cook food in a Dutch stove. It is intended only for heating, but due to its small dimensions it is very convenient to use. Quite often it is built on two floors at once.

The finishing material should be heat-conducting, but not too hot on the outside, so as not to burn. The best material for this is sand-lime brick covered with a special glaze. A significant advantage of the stove is its rapid heating and slow cooling. The consumption of material for kindling is minimal.

Location of furnaces

Home stove It's worth posting there, where is it more convenient to install a chimney. Most often, a home brazier is located in the kitchen, it is more convenient from a safety point of view. It is easier to install a chimney in the kitchen if the stove is later used for cooking. The home brazier should be covered with tiles around it, which will protect the walls from heating.

Bath stove in terms of its characteristics and configuration, it is completely different. Usually the firebox is placed in the dressing room, and the container with warm water is placed inside the bathhouse.

The quality of the material when building a bathhouse is not so important, it should be a brick that can withstand high temperatures. It is imperative that it does not have chips or damage to its integrity.

Outdoor stove are installing in summer cottages or private houses. They can replace a stove for cooking. An outdoor stove should be built from high-strength bricks that can withstand high temperatures. Porous, low-grade bricks, as well as deformed or broken ones, are not suitable for an outdoor stove.

Attention! Bricks cannot be used irregular shape, size, with chips and unevenness, without markingsMaterial that has been stored in improper conditions is also not suitable for construction.

Conclusions

In the modern world, a stove in a house, cottage or apartment is no longer a novelty, but a familiar element of decor, a device for heating the room and cooking. It is very important that it is reliable. To build the device, use high quality brick. If we talk about the interior of the stove, then for its arrangement they choose full-bodied, which can withstand high temperatures and will give off heat well.

External work can be carried out using hollow or sand-lime brick, which conducts heat well, retains it, but does not burn.

It is important to remember that before construction it is necessary to make a detailed project of the placement of the furnace. To ensure reliability, it is better to use fireproof tiles.

The peculiarity of the oven is that it keeps warm for a long time, it can be used for cooking and even for heating a sauna.

Useful video

Watch a video that shows how to test the quality of a brick by tapping it with a hammer.

The presence of such defects makes it impossible to use such bricks for laying stoves. And you need to choose specifically at construction markets, where products from several manufacturers are presented in one place and there is an opportunity to compare.