Easy to make, surprisingly effective: Bubafonya – a homemade long-burning stove

Often, home craftsmen who want to acquire a small heating stove make primitive potbelly stove, considering it impractical to design more complex products.

But there are many more a more advanced version heating unit and at the same time just as easy to make — "Bubafonya" oven.

This is a homemade top burning device that surpasses potbelly stove by efficiency and operating time on one tab.

Content

What is the essence of the top combustion principle?

In furnace and boiler equipment with top combustion firebox has the form vertically oriented cylinder. It is obvious that the fuel bookmark in such conditions will burn longer, than with the usual method of ignition from below.

At one time, the company's engineers slightly improved the technology. Stropuva, applying the following innovations:

- Air began to serve dosed and only in the combustion zone. To supply air, it was necessary to install telescopic air duct.

- So that in addition to combustion in the upper zone of the fuel load, pyrolysis, an air heating chamber was installed up to 4000°C.

Afterburning of pyrolysis and flue gases — occurs in the space above the fuel loading. By using pyrolysis, the efficiency of the plant was significantly increased.

Rationalization by Afanasy Bubyakin: a diagram of a new device

It is obvious that the Stropuva boiler is to be repeated it is impossible at home: to avoid malfunctions, the links of the telescopic air duct must be manufactured with very high precision. Afanasy Bubyakin suggested an easier way heating the air and feeding it into the combustion zone. "Bubafonya" is the nickname of this builder on one of the forums where the design was published. Later, this name was assigned to the stove.

The solution is simple:

- Place on fuel storage a bend with an air duct attached to it, coming out through the firebox cover. As the fuel burns out, the oppression will fall under its own weight, and air will always flow into the upper part of the bookmark.

- On the lower side of the oppression, use pieces of angle or channel to make hollow radial canals, along which the air will move to the periphery. During its journey, it will heat up to the required temperature.

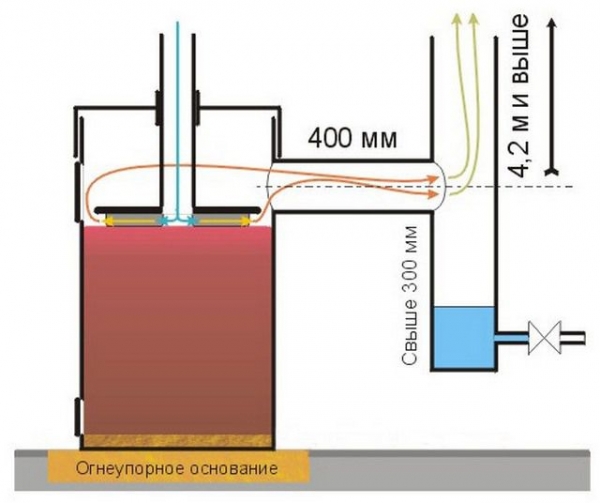

Photo 1. Diagram of the internal structure of the Bubafonya stove indicating the dimensions of the chimney and condensate collector.

The dimensions of the oppression are selected so that there is sufficient space between it and the walls of the firebox. gap for the outlet of pyrolysis gases.

How to make a "Bubafonya" with your own hands? Drawing of a long-burning stove

The device "Bubafoni" seems extremely simple. But you need to understand that the device will work effectively only when the correct ratio of parametersHere are some guidelines to consider when designing a stove:

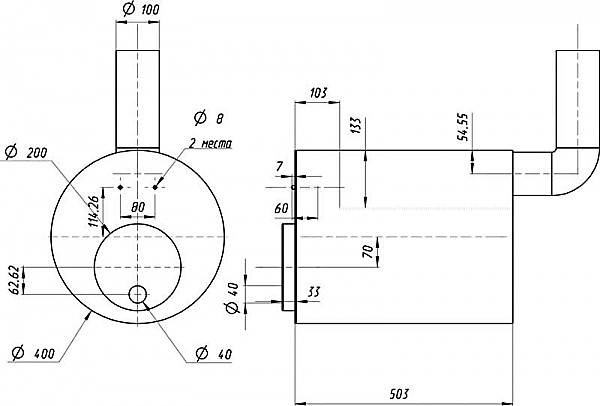

- Internal clearance of the firebox (D) should be 30-80 cm. If you make it smaller, the gases will not be able to burn completely. Therefore, the efficiency of the stove will be low. If you overestimate the diameter, the fuel combustion rate at the edges will be too low, and the bend will sink into the bookmark. As a result, the stove will go out.

- Height fireboxes (N) is taken equal to 3-5 D.

- Wall the firebox has thickness s, equal to 2.5 mm or more.

- Diameter the oppression is 0.9 D.

Height of channels (h) to heat the air mass on the lower surface of the press:

- For D = 300 mm: h = 40 mm;

- For D = 600 mm: h = 60 mm;

- for the range between D = 300 mm and D = 600 mm: h is calculated proportionally;

- For D more than 600 mm: h = 0.1D.

Photo 2. An example of a drawing of the Bubafonya long-burning stove in two projections: top view and side view.

Thickness of the oppression is being selected based on its optimal mass: it should not be too heavy, so as not to sink in the fuel, and not too light, otherwise, due to weak pressure, the fuel will flare up with back burning. The following values should be taken:

- at D = 300 mm: thickness oppression - 6-10 mm;

- at D = 400 mm: 6—8 mm;

- at D = 600 mm: 4—6 mm;

- at D = 800 mm: 2.5—4 mm.

The thickness for diameters between the specified values is calculated proportionally.

What should the furnace body be made of: a barrel, a pipe or a gas cylinder?

The most convenient make a "bubafonya" from a piece of pipe or from a liquefied gas cylinder.

The second option is the most preferable: bottom already exists, and domed top serves as an excellent chamber for combustion of gases.

The source material for the production of the case can be sheet steel — amateur sheet bending machines, which are used in small private workshops, with a sheet 2.5 mm thick they can handle it quite well.

Sometimes "bubafonya" is made from a barrel.

Manufacturing process

We will show the manufacturing process using the example of a stove made from a cylinder.

- You need a balloon fill with water, to ensure that it is freed from residual gas (without this, an explosion may occur when the container is cut).

- Draining water from the cylinder cut off the dome-shaped top and, having welded handles and clamps to it, they turn it into a lid. The remaining part weld in the pipe to connect the stove to the chimney, diameter which should be not less than 150 mm.

- After welding legs The furnace body is ready.

- We weld it to the top of the lid collar - a piece of pipe (can be made from galvanized steel), which, fitting around the air duct, will limit unplanned leakage of air masses into the combustion chamber. The gap between it and the pipe for air supply there should not be more 2.5 mm. To determine height collar, you need actual the size of the gap between it and the air duct multiply by 80. Thus, with a gap size of 0.8 mm The collar height will be 0.8*80 = 64 mm.

Photo 3. Before welding the pipe to the stove. An example of how you can easily measure a hole of the required size using a paint sprayer.

- A round piece is cut out from a sheet of steel of the required thickness. oppression, in which they then make hole diameter 75-80 mm.

- Welded to the bend in the center air duct - a pipe with an internal diameter 75-80 mm. Her length should be such that after the load is completely lowered from the collar the segment was speaking air duct length not less than 150 mm.

- A hole needs to be drilled in the air duct and install a damper (a round plate welded to a rod).

- Several are welded to the bottom of the oppression radial ribs, made from a channel or angle. They form channels for heating the air.

Please note! If the diameter of the inner space of the furnace less than 500 mm, the ribs need to be lengthened, giving them curvilinear shape (in this form they resemble the impeller of a centrifugal pump). The air must twist clockwiseThe direction of twist is determined by the Coriolis force.

The "bubafonya" stove is ready. Now it can be connected to the chimney and loaded with fuel. In doing so, consider the following:

- You need to put "bubafonya" on fireproof base (fireclay bricks will do).

- It forms in the chimney large amount of condensate, therefore it must be equipped with a condensate collector with a tap.

Useful improvements

Flaw classic "bubafoni" - difficulties with ash removal. Two options can be proposed to solve this problem:

- The easiest one: lay it down a round steel plate on the bottom with a piece of reinforcement welded to it. After the fuel burns out, this plate can easily be pulled out along with the ash.

- A more complicated solution: weld it to the body firebox door, through which it will be convenient to clean the oven.

Important! At presence of a door it will be possible to add fuel to the “bubafonya” until the current load burns out completely.

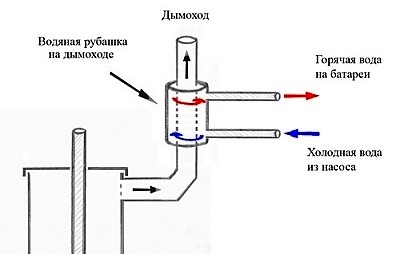

"Bubafonya" with a water jacket

It should be understood that the bubafonya is suitable for the role of a water heating device not very good.

During the absorption of heat by water, the temperature in the furnace decreases, as a result of which the efficiency of the afterburning of pyrolysis gases, and with it The efficiency of the installation drops sharply.

However, if you follow some rules, a "bubafonya" in the form of a boiler can work:

- The coolant can absorb no more than 10-15% of the heat produced.

- Firebox wall thickness should be 4-6 mm. If the thickness is smaller, the heat will go into the water too quickly, which will lead to an unacceptable decrease in temperature. If it is larger, the thermal inertia of the boiler will be so high that it will be impossible to prevent the heat carrier from boiling.

- Optimal water jacket thickness makes up 40-60 mm.

- Necessary outer shell thickness shirts are accepted on the basis of 1 mm for each unit of atmospheric pressure in the heating system (at a height of up to 2 m). Thus, the steel thickness 2.5 m, which can be bent on an amateur machine, will be able to withstand pressure up to 2.5 atm.

- Thickness there should be a water jacket everywhere the same: uneven heat dissipation will have a negative impact on the gas combustion process.

Useful video

A video showing the manufacture of the Bubafonya stove: welding features and possible errors.

Conclusions

Few heating devices arouse as much interest among craftsmen as the “bubafonya” stove: they constantly experiment with her, they try to select the best combination of parameters, to introduce some additions to the design in order to increase efficiency.

Such enviable popularity is explained by the following advantages of the design:

- bake extremely simple in production;

- has Efficiency over 70%;

- can work on one fuel load long time.

Comments