When the house is warm, the heart is happy: how to build a wood-burning stove for a summer house

A wood-burning stove is installed when you need to get rid of dampness after the cold season and retain as much heat as possible.

In the design there is nothing too complicated.

It is possible to make a stove for a summer house on your own without spending money on hiring specialists.

Content

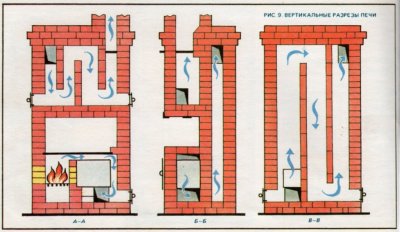

Scheme of a regular wood burning stove

A similar heating device fully under construction made of brickThe pipe is led out through the roof, and a metal sheet is used as a damper.

The main building element is brick, which has the property accumulate and gradually give away into the room heat energyThe more basic building material is used in the manufacture of the stove, the longer it will take to heat up and cool down.

When is the layout carried out? fireboxes, it is necessary to use fireproof building material and mortar. If we are talking about chimney, it needs to be lay out dry with selection and the layout of individual rows. When laying out the first ones, it is worth adhering to parallelism rules, which is checked with a special square.

To do this, you need to measure the opposite distances between the main angles. If these distances are equal, you can conclude that the masonry has been done correctly. The size of such a stove is quite large, as a rule, the device takes up area equal to 5 to 8 square meters.

Long burning stove

When making a stove, it is necessary to take into account that in the future it will work thanks to pyrolysisThis concept means fuel combustion process at high temperatures in the furnace and a lack of oxygen masses.

The peculiarity of the device is that air to support the fire it is not fed from below, but above. Such supply is carried out in doses. Air masses are supplied only to a thin layer of solid fuel. This eliminates the ignition of the load. As a result, long-term operation of the furnace and complete combustion of gases are ensured.

To make such a unit with your own hands, you will have to acquire metal barrel. It can be replaced by gas cylinder, steel pipes large diameter. Thickness there should not be fewer walls 4-5 mmIf they are thinner, they may burn out during the operation of the oven. Height the future unit is no less 1 m. The oven is divided into three sections, namely: on loading chamber, combustion zone and the system responsible for gas removal.

Stove with a hob for a summer house

To assemble the main body of such a unit, you should use special red stove brickIt has fireproof properties and, if laid correctly, can ensure the durability of the future product.

Cannot be used cement mortar, since it tends to crack under high temperatures. When making the body, special attention must be paid and the structure must be checked by drying its parts.

During laying, it is taken into account that both the room and the hob will need to be heated a little heat is enoughThe element of the oven responsible for cooking food does not require a large amount of thermal energy.

Despite the relative complexity, it is possible to produce finishing such a stove can be made of various building materials, for example:

- ceramics;

- facing brick;

- ordinary plaster.

You can also use modern ones glass wallpaper. But they are treated with distrust by many people who prefer to use elite material such as marble, granite or semi-precious stonesThus, the furnace consists of:

- from 230 firebricks red color;

- from 200 kg of clay and small sand;

- from steel angle;

- from doors blower and combustion chamber;

- from cast iron stove with burners;

- from heating boxes water and oven.

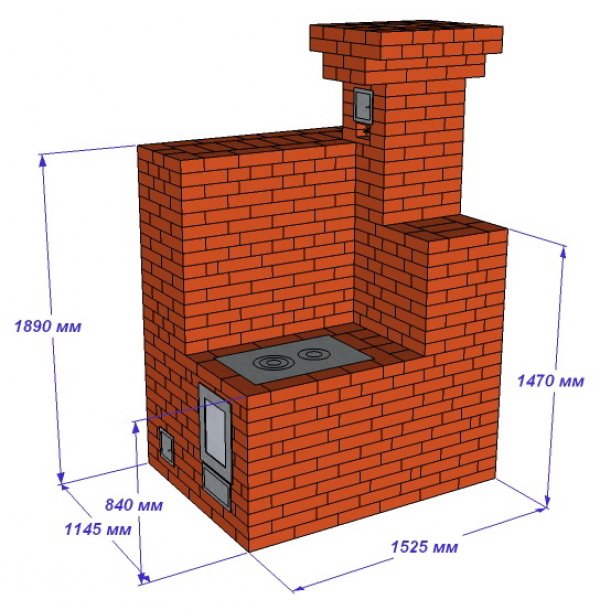

Important! Individual sizes of individual elements must be selected in accordance with the general scheme.

Selecting a project

If the owner of the dacha cannot decide what exactly he needs, then when making a decision he should pay attention:

- On number of rooms in the house that the future stove is to heat. If we are talking about heating one room, you can make such a structure as a designer addition to the interior. When you need to heat several rooms, you need to think about the possibility of connecting the stove to the central system responsible for heating.

- For that, what type of fuel the future building will be heated. A wood-burning stove is built if it is necessary to provide autonomous heating for several days.

- On frequency of occurrence the owner of the house.

- For presence a special place intended for storing fuelCoal and firewood must be stored in special conditions and care must be taken to ensure that they do not become damp.

Photo 1. Example of a project for building a country wood-burning stove with the specified dimensions.

If you take into account all the factors described when choosing a project, you can build a furnace that is most suitable for specific conditions and performs its functions. as efficiently as possible.

How to select materials?

To build the device in question, you will need:

- Solid brick red, pre-fired. The material must be fireproof.

- Clay and small sand preferably of river origin. This should be given special attention, since with the right components it is possible to make thin and neat seams.

- Crushed stone, rubble stone or broken bricks.

- Cement mortar. When choosing this component, you need to pay attention to how it is mixed. It should contain 1 part cement to 2 parts sandThis ratio is well suited for the construction of the foundation.

- roofing felt.

- Ordinary polyethylene and oil, used to lubricate the internal components of automobiles.

- Metal pipesWhen selecting this element, you need to ensure that they diameter was no less 100 mm.

- Lattice. This element of the future wood-burning stove must belong to grate variety.

- Doors, intended for the ash pit and firebox. They must be no less than 3-4 mm thick, otherwise burnout cannot be avoided.

- Sheet metal, necessary to protect the floor from coals that may accidentally fall out of the firebox.

- Galvanized wire and pipe.

Reference. If you have all the listed components at your disposal, selected in the right way, the stove is assembled without any particular difficulties.

How to build with your own hands: preparing the site

Before you post such a structure in the house, it is necessary to prepare:

- On the floor in the place where the stove will be located, special tiles are laidFor better adhesion, you need to use a primer called BetokontaktThe first row of tiles is laid perfectly level, since the quality of the entire work depends on this. Grout is applied in a dayand after installation.

- We can begin wall cladding special tile. For better adhesion, the same primer is used as in the first stage. Heat-resistant adhesive mastic is used. Apply grout also needed in a day after the tiles have been laid in full.

- Let's get started preparation of the ceiling area. It needs to be done chimney hole so that its internal diameter corresponds to the individual characteristics of the furnace. The hole must be screw on a special flange using self-tapping screws.

Important! If all the preparatory procedures are carried out correctly, it is possible to significantly reduce fire hazard level during the operation of the oven and make it easier for you to use the device in the future.

Construction of the oven itself

The procedure is carried out taking into account the following algorithm:

- It is being laid down foundation. To do this, find out how deep the soil freezes in a certain area. If the foundation is being laid in an already finished house, depth the trenches can reach half a meter. Measures are being taken related to preventing freezing buildings.

- They are being erected wallsIt is important to remember that dimensions of the blower must correspond to the dimensions of the furnace itself and provide the flow of oxygen necessary for combustion. Grate must have square shape and installed at an angle to the firebox door.

- It is being held final finishingIf the owner is more concerned about the efficiency of the structure than its appearance, he plasters the walls clay solution. After such treatment, it is necessary to apply a special coating to the structure. a mixture of chalk, water and milk.

Photo 2. The process of building a brick oven. The image shows how the grate and firebox door are installed.

If you follow the described algorithm, you can get an excellent stove that effectively heats the room.

Possible complications

If the described structure was built by non-professionals, problems may arise heat dissipation problems. They can be solved as follows:

- It is necessary to eliminate the so-called dead angle in the fireboxTo do this, the free space is filled with broken cast iron, gravel or crushed stone.

- During construction, some adjustments can be made to the design and create thermal pocketsThey will delay the release of heat, which tends to rise.

Important! Another problem is condensation formation. It can be solved by providing a short path for the gas to escape. The problem sparks appearing eliminated by installing an oven.

If you take the above nuances into account during assembly and finishing, you can significantly increase the efficiency of the stove.

Useful video

A video showing the construction of a country stove, possible mistakes and how to minimize problems with heat transfer.

Advantages of a wood burning stove

The described structures are widely used due to the following advantages:

- Simplicity a design that can free the owner from the need to purchase pipes and radiators.

- Benefit. The construction of such a device in a private house allows the owner not to pay for heating, since he will not need it.

- The presence of oxygen draft. Due to this feature, complete removal of combustion products occurs, ensuring efficient heat exchange.

Due to the listed advantages, a wood stove is found in almost every private home.

Comments

The dead spots in the furnace firebox are also described incorrectly - no filling, especially with "broken" cast iron, of these spaces is required. The firebox dimensions are simply calculated so that there are no dead spots.