Small but extremely useful: how to easily make a metal stove for your summer house?

A metal stove for a summer house is made much easier and faster, than its bulkier brick counterpart.

For construction you will need less time, expensive materials and experience, which the person who has undertaken this activity has been trained to do.

The design can easily include a heat exchanger, hob or oven.

Content

Types of metal wood stoves for summer cottages

Exists several varieties furnaces in which the role of the main building element is played by metal. Each described scheme has positive and negative sides.

Ordinary iron

An ordinary metal furnace, the operational characteristics of which are fully determined by the main building material. Iron It accumulates heat poorly and has high thermal conductivity.

Such a stove is placed on a special prepared siteto avoid any contact with wooden elements.

This prevents possible fires that occur when external surfaces become overheated.

The described feature gives advantages. A way to build a stove with high performance indicators with minimal heating appears. This is due to the fact that when using such a product, it becomes possible to use the principles of fuel combustion that do not work when it comes to a stove made of brick. This is achieved by competently using high degree of connectivity metal structural elements.

Width the metal furnace reaches 600 mm, length equals 600 mm, height taking into account the chimney pipe it reaches 1350 mm.

Metal fireplace stove

The metal fireplace stove for a summer house has interesting features useful features. The firebox is made in the form of a chamber and is placed on a special stand or support. Due to this, there is no need to install an additional foundation for such a structure.

A reliable foundation is necessary due to the impressive mass of the steel fireplace. The device of such a stove fits harmoniously into the interior country house or cottage. A pipe is connected to the firebox, designed to remove smoke masses, capable of effectively removing combustion products from the system.

To prevent accidental ignition, the surface of the stove-fireplace lined with fireproof materials.

Such a device has high efficiency, does not require special care, is unpretentious during installation, which is done in a few minutes. The fireplace is capable of heat up instantly room and can be mounted anywhere.

IN width reaches 1300 mm, height it comes to 2500 mm, and the length is leveled 1200 mm.

Making a country stove with your own hands

To complete the assembly without delays and difficulties, the following is required.

Project

If heating is required garage or other secondary premises, then preference is given to an ordinary metal stove.

It is easy to make and the device heats up quite quickly. At the same time, the unit does not require much fuel and is a type of relatively economical homemade heater. The owner will not have to spend too much money on firewood to keep warm.

If it is necessary to install such a structure inside private house or cottage, the best choice is considered to be a fireplace stove. It has lower fire hazard due to the fireproof lining. The product is able to heat up quickly and heat the room. The stove is characterized by aesthetic appearance, harmoniously fitting into the interior.

Materials

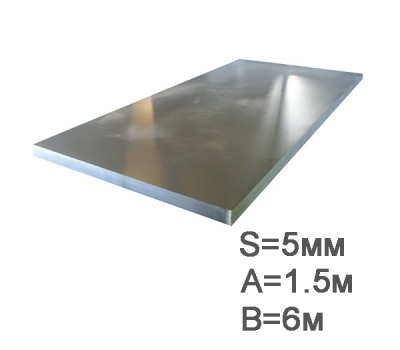

It is necessary to select raw materials for construction. As mentioned above, the role of the main building material is played by metal sheets with a thickness of 5 mm. This condition is met to avoid burnout of the walls during operation of the furnace.

To arrange the foundation you will need cement mortar and firebrick. The legs of the stove require corners, made of metal, the thickness of which is not less than 8-10 mm.

It is being prepared pipe for chimney diameter from 10 cm and of sufficient length to ensure that smoke masses exit the room.

A special platform is made in front of the firebox door, designed to increase fire safety. For the organization of which a metal sheet with a thickness of 3 mm.

High-quality materials will allow the unit to serve for a long time and heat the room properly. When choosing metal preference is given to the thickest sheets, since the ovens tend to heat up quickly.

Place for construction

To prepare a place for the stove, as mentioned above, it is necessary to limit the contact of the heating elements of the structure with the wooden parts of the interior.

To prevent accidental fire, the site of the structure is filled with small foundation, on which the stove itself will be installed in the future. Firebricks and high-quality cement are selected for construction.

Important! If you follow the above preliminary procedures correctly, you will be able to make the oven quickly and without difficulties and delays.

Manufacturing process

To correctly use the prepared materials, it is worth adhering to a certain algorithm:

- Take four metal sheets thickness not less than 8 mm and weld the edges together, you get a cube without a bottom and a lid.

- Cut out opening in one of the walls. It is intended for laying firewood, so it is worth making a larger hole.

- Embed doors fireboxes. Cut from metal of the same thickness.

- Take another sheet of metal and weld the previously prepared steel pieces to the corners. corners thickness not less than 10 mm, which act as legs for installing the structure.

- Weld the bottom to the body and organize ash-pit to control the furnace draft in the future.

- Do cover stoves. Take a metal sheet of the same thickness. Cut a hole in it, to which you will weld a pipe that will serve as a chimney.

- Make area in front of the firebox, which serves as a fire safety measure. To do this, take a thinner steel sheet and screw it to the floor under the firebox door.

- Produce heat-resistant cladding to improve fire safety. This step is optional, but following it will reduce the likelihood of an accidental fire. Which is useful if the stove is located inside a summer house or a private home.

Advice. It is quite easy to implement the described algorithm. A person can handle the assembly, skilled in handling a welding machine and wanting to save money by making a heating unit on your own that can quickly heat a room and consume a small amount of wood fuel.

It won't take much time to make. A person with little experience in such matters will be able to build a metal stove. in a few hoursIn any case, the procedure takes less time than laying a stone structure with a large number of labor-intensive stages.

Photos of stoves: compact country stove, fireplace and long-burning device

Photo 1. A small homemade iron stove, ideal for small spaces. Heats up quickly and takes up almost no space.

Photo 2. Fireplace made of metal. A fairly simple device to make, which not only heats the house, but also decorates it.

Photo 3. Homemade long-burning stove. A more complex and bulky unit that allows you to heat an entire country house.

Possible complications

One of the troubles in the process of using a metal furnace is heat loss. This is due to the fact that metal is a bad battery and quickly gives it away. To solve this problem, a special shield, which is a brick structure surrounding the oven on three sides. Before laying the walls, the building material is immersed in water to improve adhesion. If desired, the shield is faced with special tiles.

Another problem is the emergence of condensate due to the cooling of combustible gases formed during the operation of the furnace. The problem is solved by shortening the pipe, designed to remove smoke masses.

Potential troubles include unexplained smoke the room in which the working stove is located.

This phenomenon indicates that welded seams, fixing the edges of the metal sheets that form the body, not hermetically sealed.

This happens when welding is performed by an inexperienced person. To eliminate such a malfunction, the joints are welded several times. The tightness of the hull is checked with water. If no leaks are found, there will be no smoke in the future.

Rapid burnout of the bottom and walls firebox is a serious problem. To prevent its occurrence, metal sheets are selected thickness from 5 mmA body welded from such elements will not be subject to burnout and will serve reliably for a long service life.

Increased fuel consumption indicates that traction ovens poorly regulated. To get rid of this problem and reduce firewood consumption, they are equipped with special doors, performing regulatory functions.

Useful video

A video demonstrating a homemade metal fireplace stove: appearance, design features, kindling.

Conclusion

When using a metal stove, certain rules must be followed. To avoid accidental fire necessary:

- Make a bookmark refractory materials in places in close proximity to open fire and heat.

- Flammable materials near the stove separate with basalt or asbestos.

- Fence off the chimney non-combustible materials with thermal insulation properties.

Compliance with the described conditions will prevent an accidental fire from spoiling the owner’s opinion of the stove that he built himself.

Comments