The pipes don't heat up and the water from the tap barely runs? A pump to increase the pressure in the heating system will fix the situation

You are viewing the section Pump, located in the large section System components.

Low temperature in the heating system in winter may be associated not only with clogged pipes, air locks or low heating of the coolant.

Often the reason for slow water circulation in the network is low pressure in the system. This drawback can be eliminated by using booster pump.

Content

Pressure Booster Pump Design

Pumps designed to increase pressure in the heating system have a single design, which includes:

- electric motor;

- water pump.

The electrical part of the unit is reliably isolated from water. The body and parts of the pump are made of high-strength materials that are not subject to rust:

- made of cast iron;

- made of ceramics;

- made of brass;

- made of stainless steel.

The working element of the pump is impeller, it is a disk with curved blades. The impeller comes in two types:

- open — the blades are fixed on one disk;

- closed - the blades are enclosed between two disks.

The device is fixed to the pipeline using pipes.

Operating principle

The pump operates based on conversion of energy of a rotating shaft with an impeller into the movement of the pumped liquid. If the pump body is filled with water, then when voltage is applied to the electric motor, it starts to rotate rotor with an impeller attached to it.

The impeller blades give the water radial movement from the center. As a result, a vacuum area is created in the central part of the pump, and an area of increased pressure is created on the periphery. As a result, water will flow under increased pressure into the discharge pipe.

Types of booster pumps

Depending on their characteristics, booster pumps are divided into several groups:

- by type management;

- By permissible temperature water in pipes;

- by method cooling;

- by method installations.

Photo 1. Automatic pressure boosting pump model UPA 15-90, with wet rotor, manufacturer - Grundfos.

Control type

According to the control type, booster pumps are divided into:

- on automatic;

- on manual.

Automatic devices are installed in networks with unstable pressure. The devices are equipped with sensors that automatically turn on the electric motor when the pressure in the network drops.

When controlled manually, the device is on.it switches on and off forciblyIn this case, it is necessary to monitor the presence of water in the system and the temperature of the electric motor to avoid overheating.

Permissible water temperature in pipes

Booster pumps for heating systems must operate at a temperature up to +90 °C. A large number of models on the market can only withstand temperatures up to +60 °C. Such a device, installed in a heating pipe, will quickly fail.

Reference! When purchasing a booster pump, pay attention to its operating temperature range.

Cooling method

The devices are produced by:

- With dry rotor;

- With wet rotor.

In the first type of models, the pumped liquid is connected to the rotor of the electric motor does not directly contact.

The impeller and the electrical part of the engine are separated by two sealing rings, which are automatically pressed on one side by a spring and on the other by water pressure.

As a result, a hermetic connection, preventing water from getting into the electric motor. Cooling of the electric motor is provided by aluminum fins in small models or an additional fan in large ones.

Attention! Efficiency of devices of the first type reaches 80%, but the operation of the cooling fans is accompanied noise.

In the second type of models, the rotor of the electric motor directly contacts with the pumped liquid. The housing of the electric motor with the stator is sealed, and the rotor with the impeller fixed to it is located directly in the pumped medium. In this case, water plays the role lubricant and coolant.

Important! Models of the second type work practically silently, but their efficiency is 50-55%.

Installation

The following pumps are installed on the pipeline:

- horizontally;

- vertically;

- in any of these positions.

Recommendations for selection

When choosing booster equipment, you need to pay attention to the following rules:

- The power of the device is determined heating network load, which it is intended to serve.

- The permissible noise level emitted by the pump depends on installation locations. Residential buildings require the installation of quiet models; in utility rooms this indicator is less important.

- ? The choice of device depends on diameter pipes on which it is installed.

- Using different transition fittings variable cross-section reduces efficiency operation of the heating system.

- The maximum permissible operating temperature of the pump cannot be lower than the operating temperature of the heating system. (up to 90-95 °C).

- ? The dimensions of the device determine choosing the place for its installation.

- The unit's performance must comply parameters of the heating system.

Power selection

In a closed heating network of a private house, the normal pressure value is 1.5-2 atmospheres. This pressure is created with the help of standard circulation pump. In an open heating network operating with natural circulation of the coolant, the pressure does not exceed 1 atmosphere. Then, for the proper functioning of some network elements, it is necessary to increase this pressure.

The initial power value when choosing a device is the difference between the existing pressure in the network and the pressure required for the operation of the desired element. For example, for the operation of a heated floor, the pressure required is at 2 atmospheres, and the pressure in the network is 1 atmosphere. Then a booster pump is installed in front of the heated floor, increasing the pressure in it by 1 atmosphere.

If several different models meet the received parameters, then the device is selected with maximum efficiency.

Attention! Excessive pump power leads to heavy load on the heating network elements and their rapid wear.

Installation in the heating system

There are a few things to consider when installing.

Selecting a location and marking

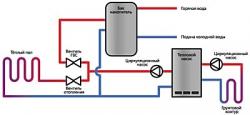

The efficiency of the pump depends on the correctness of its connection. If the device is installed on a common main line, the pressure will increase on all branches of the heating network.

In some areas the pressure will increase slightly because the total volume of the pipes creates too much resistance.

To significantly increase the pressure, a more powerful unit will be required, which will have a negative impact on energy consumption and noiselessness.

Attention! The efficiency of the booster pump installed in common highway, is small.

A more preferable option is to install a unit immediately before the element, which requires pressure support:

- before boiler heating;

- before underfloor heating system;

- before remote branch heating systems.

In other places of the network the pressure does not change. Even installation of several separate units can be more profitable than installation of one powerful device.

Reference! The pump is installed in a place that allows service device and, if necessary, change his.

In the selected place of the pipe, the section in which the installation will be carried out is marked out insert. Its length is determined by the dimensions of the device, taking into account the transition fittings and shut-off valves. Shut-off equipment is necessary to ensure that in the future there is the possibility of easy replacement of the pump if it fails. Shut-off valves are placed on both sides of the pipes, forming a pressure unit.

Wiring diagram

The pressure unit is installed according to the following diagram:

- Selected heating section overlaps, water drains from it.

- Pipe is being cut off according to the markings.

- The ends of the heating pipes are prepared for connection to the pressure unit.

It is cut on metal pipes external thread, are installed on metal-plastic fitting, are welded into plastic pipes threaded adapters.

- The burst of pipes is included pressure unit.

If the booster pump is working fickle, then the connection can be made by bypass circuit. To do this, the pressure unit is mounted parallel to the main pipe, and a shut-off valve is installed in it between the cutting points. As a result, the movement of the coolant can occur in two ways:

- By bypass, when the tap on it is open, and the taps on the discharge unit are closed. The pump does not work.

- Through pressure unit, when the taps on it are open and the tap on the bypass is closed.

Important! During installation, it is necessary to ensure that direction of water movement in pipes and direction of operation of the booster pump coincided.

Sealing the connections and checking the operation

During installation, it is necessary to provide reliable sealing of the connection points to avoid leaks during operation of the system. Sealing is performed using rubber gaskets and FUM tape.

After the installation is completed, test run heating systems when the pump is not workingAll detected leaks are carefully eliminated.

Connection to the electrical network

It is better to entrust the connection to the electrical network to specialists. They will perform the work according to the following scheme:

- A separate control panel is installed for each pump. residual current device (RCD).

- It is extended from the electrical distribution panel separate three-wire line to the installation site.

- Near the installation site of the pump unit the socket is being installed, to which the pump is connected.

- It is being held trial installed booster pump. It can be started only when water circulation in the system resumes.

Useful video

Check out this video that shows how to adjust pressure using an Oasis booster pump.

Pressure increase safety guarantees

Selection and installation of a booster pump It's better to entrust it to specialists, having a large work experience, skills and professional toolsOnly they can guarantee that the selected device will perform its functions, and the mounted connections will not leak.