Service

You are viewing the section Service, located in the large section Gas.

You are viewing the section Service, located in the large section Gas.

Installing a gas heating system in a private home involves certain electrical safety requirements.

According to the Electrical Installation Rules (PEU) it is necessary to carry out protective grounding gas boiler.

If this is not done, a fire or explosion of equipment may occur, a threat to human life from dangerous voltage may arise. You can do these manipulations yourself, without involving outside specialists.

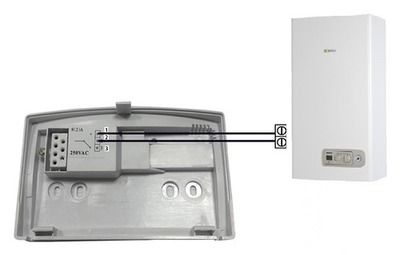

Thermostat (TS) — a device that switches the boiler on and off automatically. This occurs depending on the air temperature in the rooms and the equipment settings.

Modern boiler houses are controlled by appropriate electronic boards, which are a kind of “brain” of the device, they have a two-pin connector for connecting the thermostat.

By default, the connector is set to jumper, therefore, a boiler room without connecting the TS will operate constantly, which significantly reduces the efficiency of the system.

Even before purchasing a gas boiler, a homeowner should be aware of the requirements of gas service workers regarding its location.

A device that runs on gas is considered a dangerous device. for heating, since even a small leak leads to tragic consequences. For this reason, their installation is carried out in strict accordance with the instructions.

Usage natural gas for heating a home is the most economical solution, and in some cases the only possible option.

If all current standards and regulations are met during installation work, the gas heating system meets the highest requirements. reliability and safety.

The main task of ventilation is ensuring air circulation in a closed space — the influx of oxygen and the removal of combustion products from it.

Substances formed during the combustion of gas, if they accumulate and are inhaled by people, can lead to deterioration of health and even cause irreparable harm to health, even to the point of death.

Additionally, without proper ventilation, even a small leak of natural gas, which is the fuel for a gas boiler, can accumulate and form a flammable and explosive mixture. Lack of fresh air supply to the working boiler significantly reduces efficiency — heat output falls, and gas consumption increases.

Gas - the most popular type of fuel in places where there is a centralized heating supply. It is a cheap and widespread source of energy.

But when installing a gas boiler it is necessary strictly observe safety precautions and act according to the instructions, following all requirements and rules.

Incorrect installation can result in additional refurbishment costs and, in the worst cases, to a leak or even an explosion.

When a home is heated with natural gas, each resident saves a significant portion of material resources.

This is due to the fact that the raw materials have a high efficiency, and the price of gas is relatively low.

To save the maximum amount of money, it is important to know how gas consumption is calculated correctly.

Equipment wear is a natural process. Boilers over time lose their power and start making strange sounds, and the carbon deposits in the system become unimaginably thick.

The heat exchanger burns out. The repair costs exceed all reasonable limits. It's time to replace the boiler.

Modern gas boilers are highly technological and most often have a built-in thermostat - a device that measures the temperature and humidity of the air in the room and sends signals to the boiler board about how to produce heating.

The adjustment is done by turning the boiler power on and off. However, there are situations when it is necessary to connect additional control equipment.

In all cases, wherever it is planned to place a gas boiler, on the floor or on the wall, the installation is carried out accredited specialists from Gorgaz.

Gas supervision will allow installation, only if there is a certificate of conformity purchased equipment.

Gas heating has a wide range of advantages, so most homeowners dreaming of an autonomous heating system choose this fuel.

But such a heating system has significant drawback – although, you can install a gas boiler yourself, The devices must be installed by specialists.

According to the ignition method, heating boilers are classified into: equipment with electric and piezo ignition.

Electric start devices work automatically.

Gas boilers with piezo ignition are functioning by pressing a button.

Gas boiler complex mechanism. It can be divided into 3 main parts: electronics, gas pipes and burners, heat exchange unit (pump, tank, fan). Only the last part can be repaired independently.

Attempts to restore the first two parts, without proper skills, will lead to final breakdown boiler, gas leakage and other negative consequences.

Gas is a budget fuel, so many people prefer to heat their homes and water with it.

Legal installation procedure gas boiler quite complicated.

The preparation of documentation takes even more time than the installation itself.

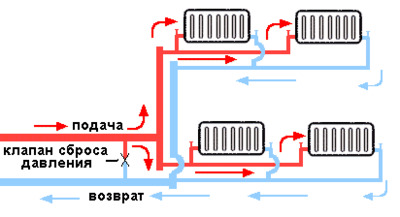

The heating system is complex design, consisting of several elements combined into one contour and is launched into operation through a chain reaction.

But it happens that the system is failing and the water in the radiators becomes cold. This may be due to problems with the return line.

The newly purchased gas boiler heats the room in the same way as silent as an electric kettle.

However, after some time (depending on how you install and configure the boiler) it may tap softly or, on the contrary, hum like a car.

Grounding a gas boiler is a necessary and mandatory condition when connecting gas to residential buildings.

This precaution will protect people and equipment from voltage and current surges, and will also serve as reliable protection against fires and explosions.

For safe operation of a gas boiler, it must be grounded in accordance with certain conditions.

Only registered devices are allowed to operate, after specialists from the gas service drew up an acceptance certificate.

A gas boiler does not belong to the category of electrical appliances, but in the process of performing its functions, the unit accumulates static electricity inside the metal frame, which is part of the design.

Over time accumulated static can cause problems, related to the control of equipment, for the proper operation of which the electronic board is responsible.

Private construction is gaining momentum, and with it the demand for modern heating equipment, which continuously supplies consumers with thermal energy for heating their homes and heating water for household needs.

Gas boiler - the central link of the gas heating system, created for such purposes. Being one of the most economical devices, it nevertheless requires its correct adjustment, ensuring proper fuel consumption and reliability of its operation.

A recently purchased gas boiler works quietly, barely noticeable to a person. If during operation the unit suddenly starts making noise, then this is a direct sign of the appearance of the first malfunctions in the system.

The fan is out of order, the walls of the heat exchanger are clogged with scale, the units of the device are worn out or the boiler is incorrectly configured - all these reasons lead to the fact that the device beeps, knocks, hums, or clicks.

The heat exchanger of a gas boiler is a structure inside which water, which is a coolant, circulates.

The water is heated by thermal energy and distributed throughout the heating system. Heat exchanger made from metals, conduct heat well: cast iron, copper, steel.