Heats up just right! How to make the perfect sauna stove with your own hands

You are viewing the section For the bath, located in the large section Types of furnaces.

Subsections: Finishing.

For any bath a quality stove is important.

This is a must-have steam room equipment present their own requirements: high heat transfer, ability to remain heated for a long time.

And also ensuring maximum temperature in the steam room, relative fire safety and protection from thermal burns.

Content

Types of sauna stoves

Bath stoves are classified according to various criteria:

- by material, from which they are made: from fired bricks, stone, metal and combined;

- by fuel used: wood-fired, diesel-fired, gas-fired, electric;

- by the location of the firebox: inside the steam room, with access to another room or outside;

- by the mechanism of heating stones, used to create temperature: with constant or periodic heating.

Simple

The device is open stove design, which is subjected to gradual heating, and the heating process itself is constant. Such a stove is made of both brick and metal.

Reference. The oven is considered to be a special feature the possibility of its rapid production, and also easy to care for.

The diagram of the furnace looks like this:

- ash pit with a door;

- a firebox with a door - opens directly into the steam room, as this simplifies its design;

- a heater located above the firebox and subject to constant heating due to the fire;

- chimney.

Although such a stove is simple in its design and easy to maintain, from a safety point of view, it raises many questions.

The main point in this regard is the presence of a firebox with a door inside the steam room - due to the small size of the room when adding firewood you can get a serious burn.

It is not possible to stock up on firewood directly in the steam room — due to the high temperature inside the room, they will quickly become damp, which will negatively affect their quality.

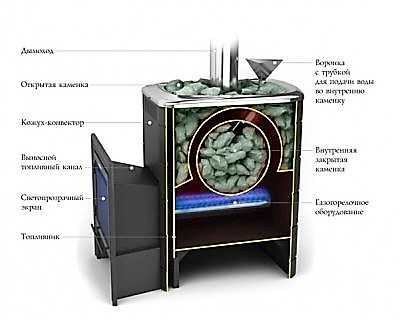

Round

A round stove is most often made of metal. It is located inside the steam room, but due to its relatively small dimensions, such a design is considered safer. Total height of the stove (including the chimney) can reach three meters.

The diagram of the furnace looks like this:

- ash pit with door — the door can be replaced with a permanently open grate;

- firebox with door — in some cases, a door with fireproof glass is installed to monitor the flame condition;

- heater - can be either open or complex, the latter consists of two parts: one is located directly above the firebox and is subject to constant heating from the firebox, and the second is on top of the body;

- chimney with a water tank located around it: to create additional steam.

The main difficulty in using the oven is considered to be heater maintenance, located inside the firebox.

Black sauna stove

The furnace diagram is simple:

- a stone recess for placing firewood;

- On top it is covered with a grate, on which stones are fixed.

Photo 1. A brick stove for a bathhouse, which is heated in a black way. The upper part of the device has a heater, there is no chimney.

There is no chimney, as all the smoke comes from the wood. is removed through the windows and doors of the steam room.

Attention! Device quite dangerous, since open fire is in the access zone, as a result of which the distribution of such stoves is currently small (mainly in ethnographic complexes).

Stone

The structure is built according to various designs, including the method of lining the metal base with stones. The total weight of the furnace can reach several tonsHowever, the construction of a powerful foundation for such a stove is not required, since the main heating load falls on the metal firebox, which, despite the thick metal used, weighs comparatively less than a completely stone stove.

The stone structure is a structure that is built using fireclay materials (clay or fireclay powder). Externally, it looks like a combination of two projects - a black stove and a brick one, and Its scheme is a combination of several elements:

- blower with door;

- fireboxes;

- heaters;

- chimney.

If the design of a stone oven is based on the black oven scheme, then no blower required, since the entire structure will be erected around a recess in the foundation, which will allow for a natural flow of air.

On gas

Gas sauna stoves are now widely used because do not require additional maintenance costs, and the main heat carrier is gas, which is supplied through a gas pipeline or from a specially connected gas cylinder.

Construction diagram:

- brick base on which the device is installed;

- the oven itself;

- hot water tank;

- a chimney with a double-circuit pipe installed for fire protection.

Inside the oven consists of from a gas burner and special pipes, through which the gas source is hermetically connected.

The hot water tank can be used to supply the washroom and, if necessary, to heat the entire complex. For the latter purpose, the tank is made flow-through with special drain cocks.

How to make a device with your own hands

Each sauna stove is made according to a strict algorithm, consisting of the following steps:

- project development;

- preparation of suitable materials and tools;

- selection of a place for construction;

- construction of a foundation or brick base;

- installation or assembly of a finished structure.

Important! Each stage has a direct impact on the final result, for this reason it is better pay attention to every step.

Choosing a project for a homemade stove, drawing

The project for the construction of a sauna stove is being developed based on special requirements, presented to the heating product.

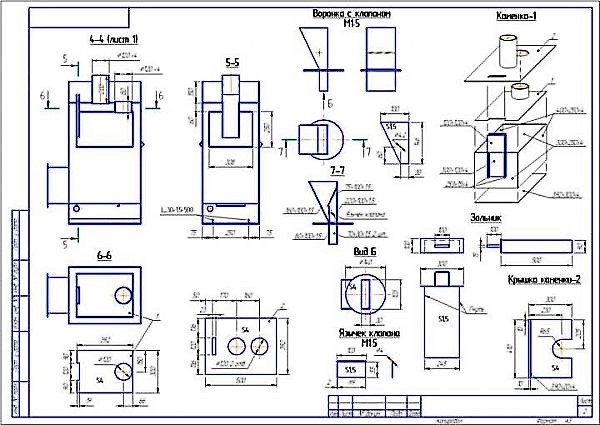

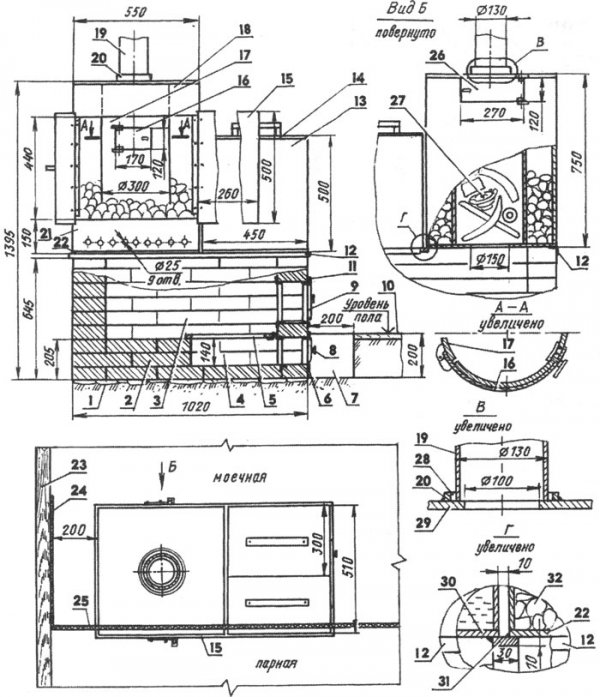

Photo 2. Detailed drawing of a metal sauna stove, the dimensions of all parts of the device are indicated.

Key points to consider when choosing projects:

- area and volume of the steam room;

- maximum temperature of the heater;

- materials, as well as the ability to use a ready-made structure with modern heat carriers (gas or electricity);

- construction budget;

- decorative design.

Photo 3. Drawing of a brick stove for a bathhouse with the size of the device indicated. Stove with a closed heater.

Preparation of materials and tools

If we are talking about building a brick or stone oven, To build it you will need:

- fireclay brick;

- fireclay clay or mortar powder;

- sand and cement for the foundation;

- cast iron doors for the ash pit and firebox;

- metal corners for laying bricks or stones;

- reflective metal heat-insulating screen for installation in places where the stove touches the walls of the steam room;

- grate;

- Stones for the sauna: the most suitable option is boulders from the river or sea bottom that have undergone long-term treatment with water.

If we are talking about a metal furnace with different heat carriers, then For its construction and operation you will need:

- brick and cement for installing the stove base;

- metal pipes for the chimney and coolant supply (if the stove will not be fired with wood);

- metal corners for fixing the stove;

- heat-reflecting screen to ensure the safety of the structure.

The following tools will be needed:

- buckets;

- shovels;

- trowels and floats;

- level and plumb lines;

- welding machine and electrodes (for mounting metal elements);

- hammer;

- grinder and cutting wheels.

Attention! When working with a power tool, be sure to use of protective elements - glasses, mask, gloves, and clothing that protects against damage.

Place for construction

When constructing a sauna stove, it is necessary to form a foundation, which is built independently of the foundation of the bathhouse itselfBefore constructing a stone oven, the walls around it must be strengthened and covered with heat-insulating material.

A pit of depth is dug for the foundation from 40 to 60 cm, and its size must exceed the dimensions of the structure by no less than 10 cm on each side. The pit is first filled with sand and crushed stone, everything is compacted on top and covered with mortar. The top layer is reinforced.

Important! The solution is made plastic and pour in two layers, to achieve the highest quality solidification.

How to build correctly, order

The installation of a sauna stove begins with laying a layer of any kind non-combustible heat-insulating and moisture-proofing material, to avoid destruction of the foundation from constant temperature changes. The seams should not exceed four millimeters, because otherwise they will begin to quickly deteriorate, and smoke from the wood and carbon monoxide will flow from the stove into the steam room.

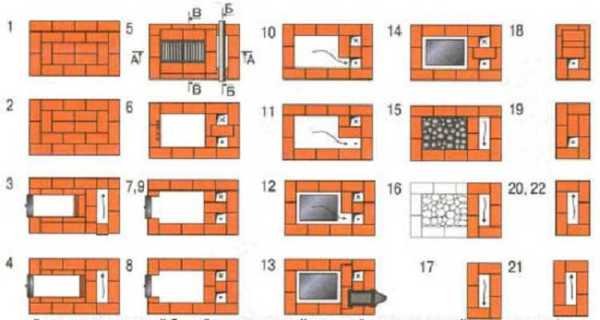

Photo 4. Option for laying out a brick stove with an open heater. Construction includes 21 stages.

The laying of the stove is carried out in the following order:

- first row laid out evenly to avoid further deviations from vertical and horizontal planes;

- each subsequent row is installed according to the diagram, and after completion, it is checked with a level and a plumb line for evenness of the layout;

- in the second row the laying of the ashpit begins;

- in the third row the ash pit door is being secured;

- fourth row is laid out without changes according to the selected scheme;

- in the fifth corners are placed to secure the grate: it is laid loosely;

- from the sixth to the tenth row the firebox is made of fireclay bricks using clay, since such bricks cool quickly;

- on the eleventh row metal corners are laid out, on which the vault of the firebox is subsequently formed;

- the firebox door is secured, and it is advisable to wrap its edges with a basalt stove cord, which will compensate for all expansions and contractions under temperature influence;

- After the construction of the firebox is completed, the heater is formed according to the diagram, which can be either open or closed - in the latter case, a chamber is built for placing stones, the door of which allows you to easily load stones inside and take them out for washing and sorting;

- A chimney is installed from the heater according to the diagram, into which, if necessary, a hot water tank can be installed.

How to connect a gas sauna stove yourself

A gas stove for a sauna can only be safe if it correctly installed and connected.

There are a number of requirements for installation.:

- The distance from the stove to the wall is not less than 50 cm, covering the walls with non-combustible materials or installing heat-protective screens.

- The base of the furnace is made of firebricks and extends beyond the edges of the furnace by at least 10 cm on each side.

- If the burner used is installed without special pads, the edges of the opening must be the same size from 48 to 60 cm height and 35-48 cm width; if an overlay is used, the dimensions increase up to 62-65 cm, and the height is up to 52-67 cm.

The chimney has its own requirements:

- pipes used in construction are made of stainless steel;

- the connection between them is made by sliding one sector onto another by no less than half the diameter of the lower pipe.

The gas stove is installed in such a way that the burner goes into the dressing room. Wall thickness should not exceed 30 cm.

Possible complications

When building a sauna stove, the following difficulties may arise:

- the seams between the bricks are increasing — this problem can only be corrected at the construction stage before the mortar hardens by dismantling the masonry;

- long-term solidification of the solution - speed up the process by drying the structure with small fires;

- release of carbon monoxide and smoke into the room during the combustion process — can only be corrected by disassembling the entire structure.

Useful video

Watch the video, which demonstrates the process of laying a brick sauna stove with a water tank.

In conclusion

In order for the operation of the sauna stove to be safe, the device must be built with strict adherence to design requirements, and it is important to ensure constant draft in the chimney to minimize the risk of carbon monoxide being released into the steam room.

Comments