The best device for environmentally friendly and inexpensive heating of your home is a gas boiler!

You are viewing the section Gas, located in the large section Boilers.

Subsections: Service, Accessories, Double-circuit, Wall mounted, How to install.

A gas boiler is a unit that acts as a as a central element of a liquid heating system.

Such equipment is actively used to provide heat supply to both entire buildings and individual premises, in particular apartments.

The wide use of heating structures is primarily due to low cost of gas, used as a fuel, as well as high efficiency rates, autonomy and safety of operation.

In addition, among the unconditional advantages are: environmental friendliness, ease of use, as well as a long service life of the structures.

Content

Application of different fuels for gas boiler

When operating the devices, gas is used as an energy source. Most models operate on both main and liquefied gas — methane and propane-butane respectively. At the same time, each of the listed types of fuel has certain advantages and disadvantages.

Main gas

Heating with mains gas - the optimal way of heat supply private housing, primarily due to the low cost of energy, as well as the high efficiency of modern gas boilers.

When using a centralized gas pipeline, there is no need to allocate space for fuel storage. The operation of the boilers is characterized by the absence (or minimal level) of noise, odor and smoke, as well as high safety indicators.

The disadvantages of main gas include:

- Potential dangerHowever, modern gas equipment minimizes this disadvantage.

- No connectivity. Not all regions are still connected to the centralized gas pipeline.

- Gas supply interruptions. If the gas pipeline stops working, the house will be left without heating. However, most models of gas boilers are universal, which allows using liquefied gas from cylinders in such situations.

Liquefied gas

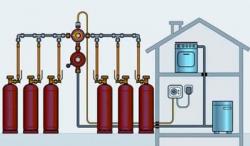

Liquefied gas from cylinders was widely used as an energy source throughout the twentieth century due to the insufficient level of gasification in many regions.

At present, in addition to cylinders, gas is also stored in gas holders — sealed tanks with a volume of from 5 to 10 m3, buried underground.

Gas tank refilling required from one to two times a year.

The advantages of using this type of fuel are practically no different from the advantages of main gas, while among the disadvantages stands out comparatively high cost of both the fuel itself and the maintenance of the gas tank and/or cylinders.

Reference. Despite the high cost of liquefied gas one and a half to two times cheaper than electricity or diesel fuel.

Heating gas boilers: what are they, their types

The range of gas boiler models available for sale is wide - the differences concern not only the design, but also a number of technical characteristics, and also operational features.

In this case, the operating scheme (except for some nuances) the same for all models: In the combustion chamber of the boiler, an air-gas mixture is burned, due to which thermal energy is generated, which is used to heat the coolant circulating in the heating circuit. The design of all designs also differs little, the main differences concern the functional characteristics.

Modern gas boilers are classified according to the following features:

- installation options;

- connecting an additional water circuit;

- type of air draft and combustion chamber;

- ignition method;

- method of using fuel energy;

- heat exchanger material.

Mounting options

Depending on the installation method, gas boilers are divided into floor and wall models. As follows from the definition, floor-standing gas boilers are installed directly on the floor or a pre-prepared foundation, while wall-mounted boilers are attached to the wall.

Photo 1. Wall-mounted gas boiler for heating, located in the kitchen. Due to its small size, the device fits into a kitchen cabinet.

In addition to the installation method, floor models differ from wall models. larger dimensions and weight, as well as greater power. At the same time, wall-mounted gas boilers are cheaper, but they break down faster. Most floor-mounted models are energy-independent, while using a wall-mounted device requires a constant connection to the power grid.

Floor-standing boilers are ideal for heating large areas, however, their installation requires the arrangement of a specialized room - a boiler room. Installation of wall-mounted models is permissible without allocating a separate place for the boiler room, but their installation is allowed only subject to compliance with a number of rules established by current legislation regarding the operation of household gas equipment.

Number of connected heating circuits

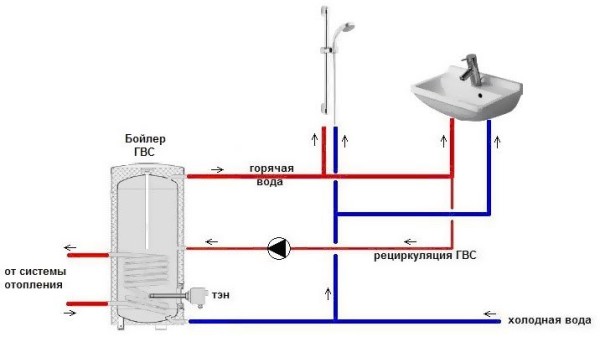

Gas boilers also differ in the number of connected water circuits. Single-circuit The options allow you to connect only the main water circuit, which is directly responsible for heating. Double-circuit The models have two circuits, one of which is responsible for heating, the second for hot water supply.

Photo 2. Diagram of a heating gas boiler with two water circuits. One of which performs heating functions, the other - hot water supply.

Average price of a dual-circuit unit lower compared to the cost of a single-circuit analogue in tandem with a boilerHowever, the efficiency of a double-circuit gas boiler decreases with an increase in the number of users.

Important! Dual-circuit options are more susceptible to scale formation on internal surfaces, which can lead to gradual decrease in efficiency and significant increased fuel consumption.

Type of air draft and combustion chamber

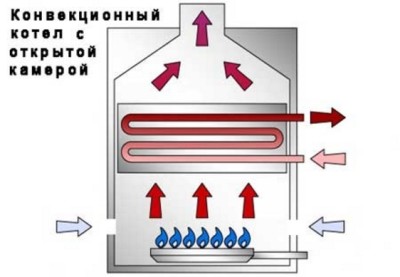

Depending on the type of air draft, gas boilers are divided into models with natural and forced draft. In this case, the type of combustion chamber directly depends on the implemented principle of air and combustion products circulation.

In models with natural draft, air supply and exhaust gas removal are carried out due to natural circulation of air flows, since these boilers are equipped with open combustion chambers. The burner operates using room air, and combustion products are discharged through a fixed chimney.

The advantages of such boilers include: They highlight independence from the power grid, lack of noise during operation and low price. Among the disadvantages — dependence on the pressure level in the gas pipeline: with sharp changes, the risk of burnout or extinguishing of the burner increases, and gas overconsumption is possible.

All models with forced draft are equipped with closed combustion chambers.

Air supply and exhaust gas removal produced using a built-in turbine through a coaxial chimney, which is brought out to the street through the wall.

The operation of a forced draft gas boiler does not depend on the pressure in the gas pipeline, however, such units require uninterruptible power supply, the designs are very noisy. Installation of a coaxial chimney is inexpensive, although the cost of models with forced draft is higher compared to boilers using natural air circulation.

Reference. When operating a unit with a closed combustion chamber indoors the natural oxygen level does not decreaseIn addition, to install the boiler, there is no need to install a traditional chimney.

Method of ignition of the burner

Depending on the specific model, the burner ignition is done manually or automatically:

- In the first case When the corresponding button is pressed, the piezoelectric element is activated, igniting the air-gas mixture in the combustion chamber. The main disadvantage The advantage of such gas boilers is that the need for manual re-ignition when the burner goes out. In this case, the operation of the unit with piezo ignition does not depend on the power supply.

- In the second case the burner starts automatically - depending on the specified settings. In such boilers there is no pilot light, which is to a large extent reduces fuel consumptionIn addition, if the power grid fails, the gas supply will stop and the burner will ignite automatically when normal electricity operation is resumed.

Method of using fuel energy

Despite the general operating principle, depending on the type of use of energy generated by burning fuel, commercially available gas boilers are divided into classic convection and condensation models.

In classic convection In boilers, the coolant is heated exclusively by heat generated directly from the combustion of gas.

In this case, part of the thermal energy is lost, since it is contained in the combustion products discharged through the chimney.

Condensation models are equipped with a secondary heat exchanger, which allows for the extraction of additional volumes of thermal energy by transforming the aggregate state of combustion products, i.e. the formation of condensate.

The efficiency of condensing boilers is higher than that of convection models and exceeds 90%. At the same time, condensing units have compact dimensions, are lightweight and do not make noise during operation. The volume of emissions of harmful substances compared to traditional devices 70% lowerHowever, condensing devices are significantly more expensive than their classic counterparts and are very sensitive to air quality.

Attention! The use of a condensing appliance requires timely disposal continuously formed condensate with a high content of acids and other chemically active substances.

Heat exchanger material

The heat exchanger is one of the main elements of any gas boiler. In most models, heat exchangers are made made of steel or cast iron. As a rule, cast iron heat exchangers are equipped with floor-standing boilers, while steel is usually used in wall-mounted models. Each material has a number of advantages and disadvantages, the degree of manifestation of which is primarily depends on operational factors.

Cast iron heat exchangers more durable, less susceptible to corrosion and have better thermal conductivity. At the same time, they are very sensitive to mechanical impacts, coolant quality and temperature changes. Due to the brittleness of cast iron, microcracks often form on heat exchangers due to various circumstances, which contribute to a significant reduction in their service life.

Photo 3. Floor-standing gas boiler made of cast iron. The color of the device is gray with red.

Steel heat exchangers are less resistant to corrosion, as a result of which the service life of these elements is shorter compared to cast iron analogues. At the same time, steel heat exchangers are resistant to temperature changes and mechanical impacts. In addition, steel heat exchangers are cheaper than cast iron analogues.

Reference. The average service life of a boiler with a cast iron heat exchanger is 35 years old, for a boiler with a steel heat exchanger, this indicator varies within the limit from 15 to 20 years old.

Useful video

Watch the video, which explains how to correctly calculate the required power of a gas boiler for your home.

Important characteristics

Efficiency of any gas boiler depends on the following factors:

- Power and fuel consumption figures.

- Cost of the boilerOften, more expensive models quickly pay for themselves due to additional technological solutions.

- Quality of assembly and materials used - ease and safety of operation.

Heating efficiency is also affected by the characteristics of the building or premises being heated: its area, the quality of thermal insulation and the level of natural heat loss.