Construction issues

You are viewing the section Construction issues, located in the large section Bake.

You are viewing the section Construction issues, located in the large section Bake.

The wood burning stove is working thanks to the principle of traction. Hot gases released during combustion rush up the chimney, giving off heat to the heat exchangers along the way.

To create a draft, a properly calculated chimney is needed. Ceramic bricks have long been used for this purpose, thanks to their properties baked clay.

When designing a heating system It is very important to check the compliance pipes and stoves - brick is not suitable for all systems.

Oven doors are widely used and are made from a variety of materials: cast iron, metal, panoramic glassThey are found on the firebox openings of all stoves and fireplaces.

By opening the door you can add more firewood, regulate temperature, and watch the burning logs through the glass.

Cast iron cooking surfaces are used in wood-burning stoves. They serve for heating the room and cooking.

Cast iron has the ability warm up evenly over the entire surface and slowly release heat, heating the room.

The grate is a grate that is installed between the firebox and the ash pan of the furnace. It promotes more efficient combustion of fuel.

After part of it has burned, the ash falls down through the holes. The remaining part goes down and burns more intensely, because air enters through the grille.

The part is made from materials that are resistant to temperature effects: cast iron or heat-resistant steelAt the same time, cast iron grates last longer, as they are more durable.

The design of the furnaces provides for several types of doors. Firebox doors, as the name suggests, close the firebox. When using them during combustion sparks and embers do not fall out, which significantly reduces the likelihood of a fire.

In addition, thanks to the firebox door combustion efficiency increases and is supported even temperature inside the stove.

Furnace firebox – one of its main elements, designed for combustion of fuel materials.

Any firebox must provide an oxygen supply to maintain the fire, complete combustion of fuel, the release of flue gases and the removal of ash.

Firebox design is determined depending on the type of furnace and type of fuel.

When the oven is in operation, its surface becomes very hot. For safety, the device is placed at a certain distance from the walls: not less than meters for metal structures and half a meter for brick.

But this arrangement is not always convenient, especially in small spaces. To avoid damage to surfaces and, especially, fire, put protective screens. They also promote gentle heating and protect against burns.

A smoke exhaust pipe is one of the key elements any heating device that runs on solid fuel.

Chimney removes hot gases to the outside, provides traction, necessary for the correct combustion process of fuel in the combustion chamber.

From the chimney in many ways depends on the efficiency of the furnace, the efficiency of its additional functions and the features of heating the air in the room.

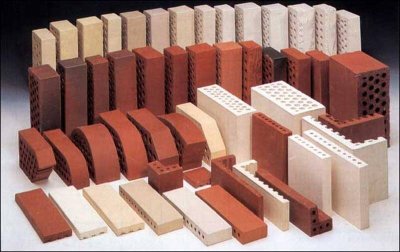

Materials for building a stove or fireplace are selected based on their characteristics.

There are several types of adhesives for ovens. Heat-resistant, heat-resistant up to +140 °C.

Heat-resistant, maintaining strength even with temperature fluctuations from -10 to +140 °C; heat-resistant and heat-resistant, capable of withstanding heat from 1000 °C; fire-resistant and fire-proof, do not lose their properties when exposed to open flame.

Along with modern heating systems that run on liquid fuel or gas, many people living in private houses prefer stoves and fireplaces.

At the same time, consumers choose for themselves not only functionality heating device, nand its exterior decoration.

Currently methods of registration ovens diverse. The most popular methods are plastering and universal painting ovens, decoration tiles or lining natural stone and tilesThe common criterion for all the listed finishing methods is their resistance to high temperatures.

High-quality plastered brick ovens are not only interior decoration, but also significantly increase strength and reliability structures, ensure its tightness and resistance to cracking.

Plastering is effective prevents smoke penetration through holes in old brick ovens.

Prevents occurrence in new designs chips and cracks, which may arise due to temperature changes in the furnace, eliminates the possibility of smoke on the walls and makes the operation of the furnace more secure.

To ensure reliability and stability In order to maintain the design of the furnace and prevent the loss of its original appearance and functionality, it is necessary to build a reliable support.

Without a properly constructed foundation, brickwork can become warped over time, requiring large repair costs, so It is worth thinking about its design and layout in advance.

The foundation should be installed with sufficient or a small margin of safety.

Chamotte clay mortars differ from conventional clay-sand pastes increased heat resistanceThey are used for laying the firebox, since the bricks in this area are exposed to high temperatures.

The dried fireclay mixture has high strengthA firebox laid out using such material does not require repairs for several years, even with constant use.

A stove is a structure that in the modern world competes equally with heating devices.

It is used not only for heating, but also for cooking. Heating technology has a beneficial effect on the human body and does not dry the air.

Since ancient times, it has been customary to build a stove with your own hands, putting positive energy into each brick.

A well-built stove serves for decades and does not require major repairs.

When creating such devices, several types of solution are used: clay, lime, lime-cement and cementSand is added to all mixtures.

The main part (body) ovens are often laid out using clay mortar, for foundation The craftsmen use cement. For chimneys cement or lime-based mixtures are suitable. Less condensate (soot) settles inside the chimney on the limestone masonry. Furnace mixtures can be prepared independently or purchased at a hardware store.

Despite the wide range of modern heating equipment, many people prefer to use a stove, made by hand.

This way it is possible save on utility bills, and the most important thing is that the stove creates the desired microclimate at any time.

Today's masonry does not have an archaic appearance; the stove can fit perfectly into any interior.

The main point in choosing a stove or fireplace is the mortar for masonry. This is important, since the quality of the masonry mixture depends not only on reliability of the future design, but also proper functioning of the structure.

Clay mortar for stove masonry is made from natural materials.

Clay has the same coefficient of linear expansion as bricks made from this raw material.

The solidified clay mixture is a strong and durable material, it does not deteriorate decades.

During operation of the furnace are gradually being destroyed. The firebox walls lose strength from the heat. Bricks burn through and break off, masonry joints crack, and soot accumulates inside the wells and on the walls of the chimneys.

High temperature load the firebox door, the hob, and the grates are exposed. In the northern regions, in freezing temperatures, firewood has to be burned every day, which gradually leads to the destruction of the stoves.

The oven has an ancient history, but even today it is capable to enliven any interior and even become its central part.

Various methods are used for this, and the most popular of them is tiling. This technology has existed for several centuries and has not lost its relevance to this day.

Thanks to her simplicity and use inexpensive materials, it is not necessary to involve experienced specialists in the work; you can do it yourself.